The most accurate layouts and pricing typically come from a successful relationship between you and your salesperson with your current conveyor system provider. But time between pricing and revision exercises can slow down the process and get in the way of your delivering your proposal to your customer.

There’s a better way to deliver accurate, impressive 3D solid model automation strategies. There’s a faster way to deliver assembled pallet and multiple strand conveyors (and more) to your customers. It’s as simple as using an in-context configurator and conveyor software and partnering with an assemblies manufacturer who has optimized the processes for speed.

Faster Concept Delivery

Speedier delivery to your customer starts with a faster design process. Today, you may spend days or even weeks and several phone calls to receive updated part numbers, pricing, and delivery dates from a conveyor vendor. The updated process using an in-context configurator cuts down time for your process significantly while giving you high detail and accurate layouts perfect for 3D solid modeling. In short, the process would now look like this:

- Download the software files from the website and save locally

- Open the Microsoft® Excel-based IMPACT! configurator

- Develop configurations in Excel along with embedded applications support tools

- Transfer the data from IMPACT! automatically (via behind the scenes advanced API bridge) to SOLIDWORKS (upload-able files are available for other CAD programs if you are not using SOLIDWORKS)

- 3D models are generated; Excel keeps accurate and dynamic part numbers and pricing

- Modify to suit in SOLIDWORKS, and Excel bill of material where pricing and part numbers will remain accurate and be constantly updated

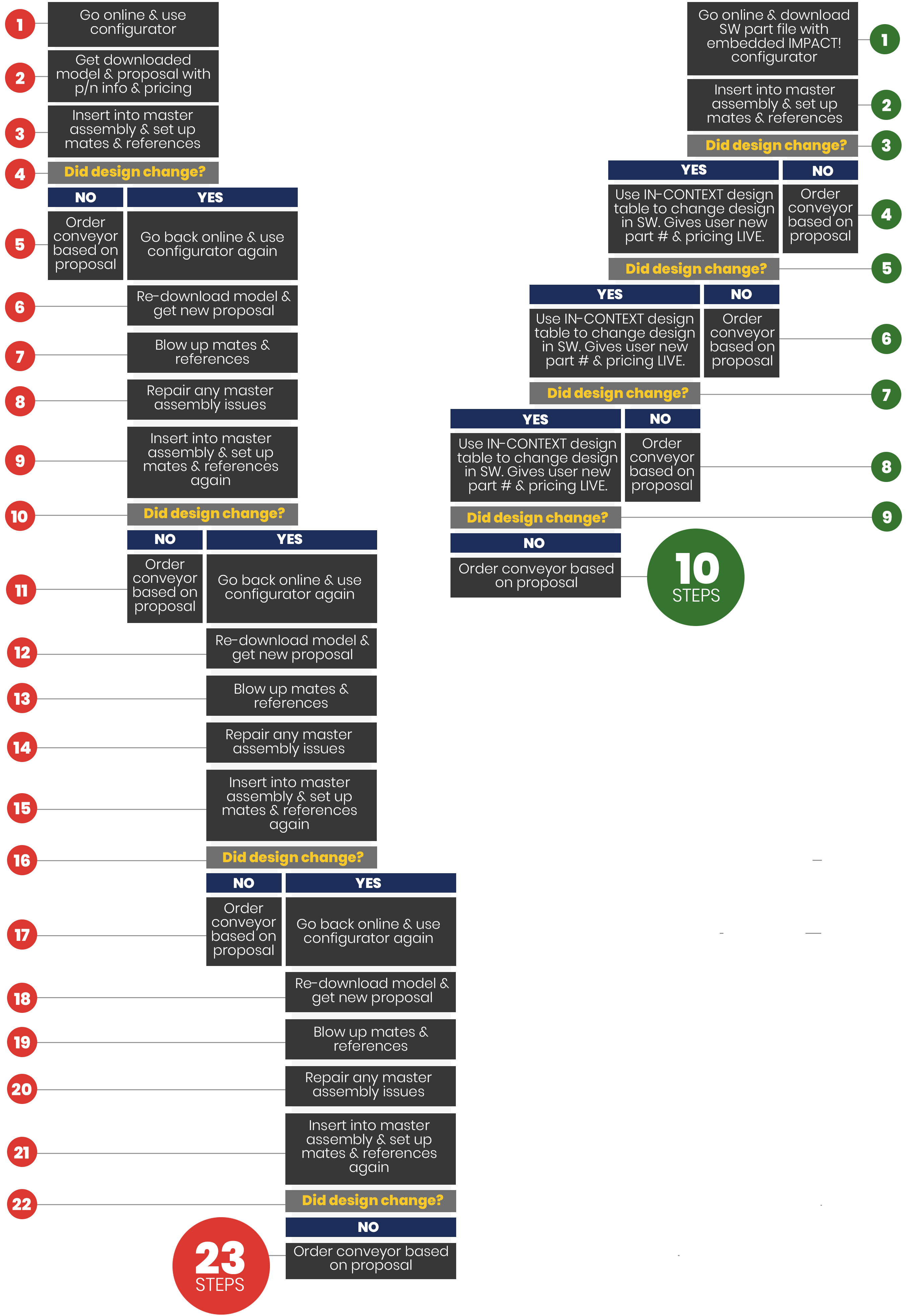

This graph highlights the difference between other configurators and an in-context configurator when it comes to design change speed.

CONFIGURATION TOOL PROCESS DEPICTING 3 DESIGN CHANGES

TYPICAL ONLINE CONFIGURATION TOOL VS. GLIDE-LINE IMPACT! CONFIGURATION TOOL

Using the in-context configurator, you eliminate the previously necessary “middle man,” plus the time it took to go back and forth for accurate pricing and modeling.

Faster Dual and Multi-Strand Conveyor Assembly Delivery

Once you use the Glide-Line IMPACT! configurator, you’re able to give your customers beautiful 3D solid models upfront. But the kicker comes when the multiple strand conveyors are actually ordered from Glide-Line.

Once ordered, the conveyors for your automation system arrive in half the time compared to other suppliers, thanks to the automated nature of the configurations and the automated method we’ve developed to drive our internal processes.

The entire world of conveyor possibilities is open using configurable modular conveyor designs from Glide-Line, and the speed with which you’re able to deliver 3D model designs can truly help to ‘wow’ your customer. Then, forget about the long wait times and delays from other providers; Glide-Line delivers assembled multiple strand (and more) conveyor systems in half the time.

Learn more about customized conveyor designs with increased flexibility and speed and dynamic configuration planning in our new ebook, Customized Conveyor Design Guide: From Configurable Conveyor Technology To Your Automation System.

Leave a Comment