Flexible.

pedigree, we offer solutions for all budgets,

industries and complexities.

Flexible.

pedigree, we offer solutions for all budgets,

industries and complexities.

Flexible.

pedigree, we offer solutions for all budgets,

industries and complexities.

Flexible.

pedigree, we offer solutions for all budgets,

industries and complexities.

Flexible.

Flexible.

Flexible.

Flexible.

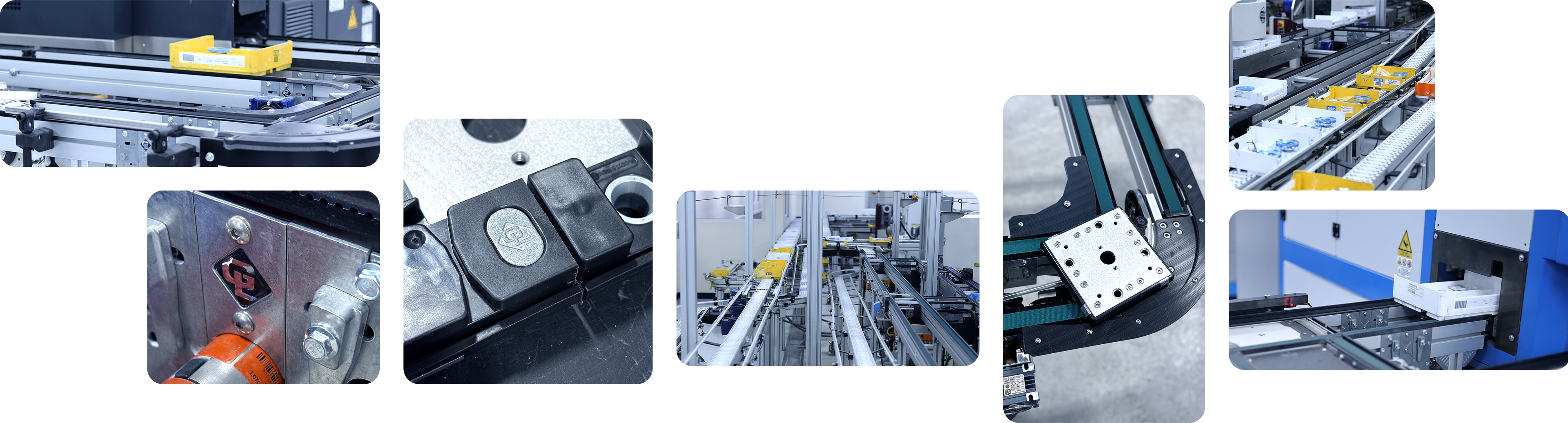

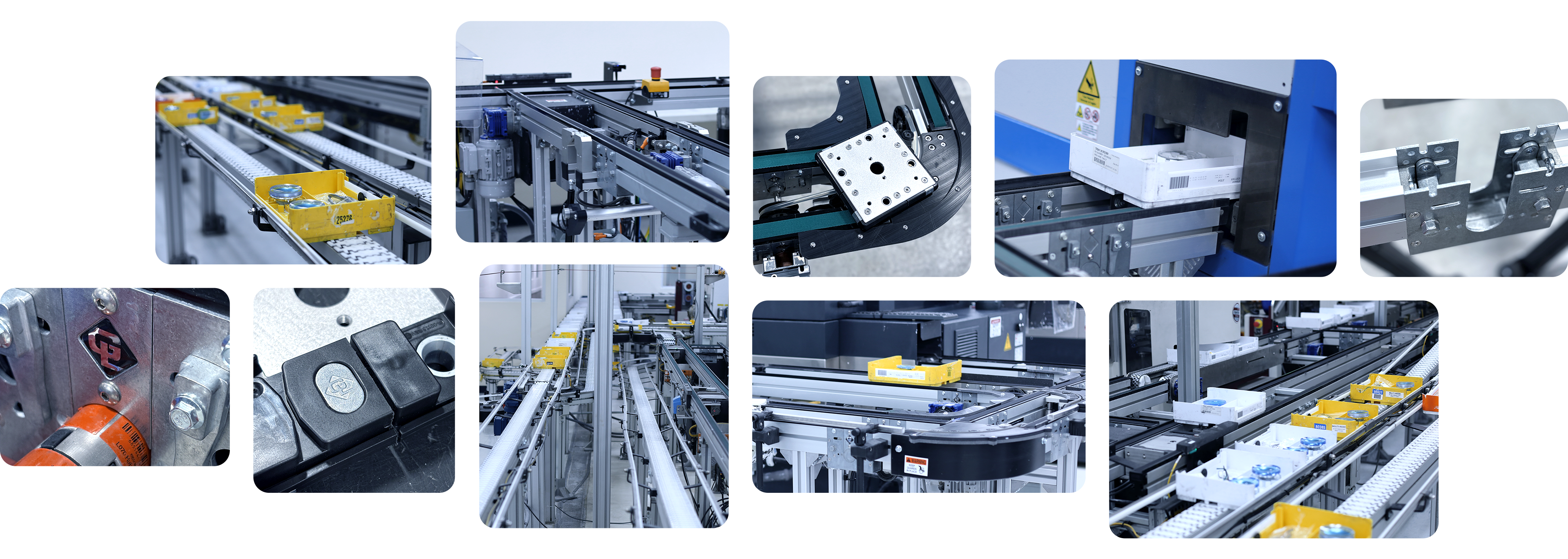

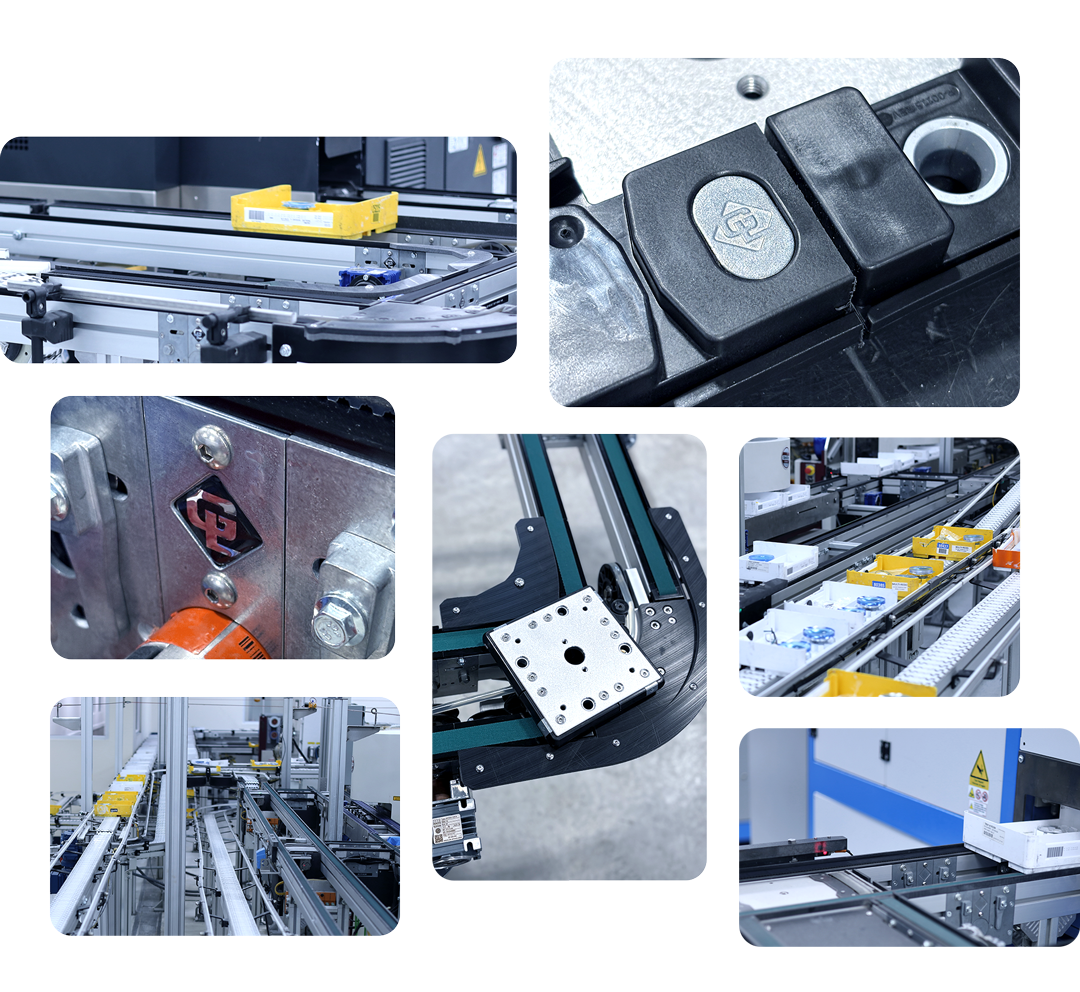

With over 40 years of conveyor manufacturing pedigree, we offer solutions for all budgets, industries and complexities.

Working with Glide-Line is fast: from quoting to lead time to delivery. Each of our conveyors is designed and built with flexible configurability and elegant motion, creating an efficient, hassle-free customer experience. We strive to be the easiest conveyor system manufacturer to work with, and our customers agree!

Working with Glide-Line is fast: from quoting to lead time to delivery. Each of our conveyors is designed and built with flexible configurability and elegant motion, creating an efficient, hassle-free customer experience. We strive to be the easiest conveyor system manufacturer to work with, and our customers agree!

Shaping the Future with Turn-Key Conveying Automation

Hear what one of our valued partners has to say about their 10 year Glide-Line journey.

What’s New at Glide-Line

Blog

Improving Production Efficiency in the Home Furniture & Appliance Manufacturing Industry With Modular Conveyors

Press Release

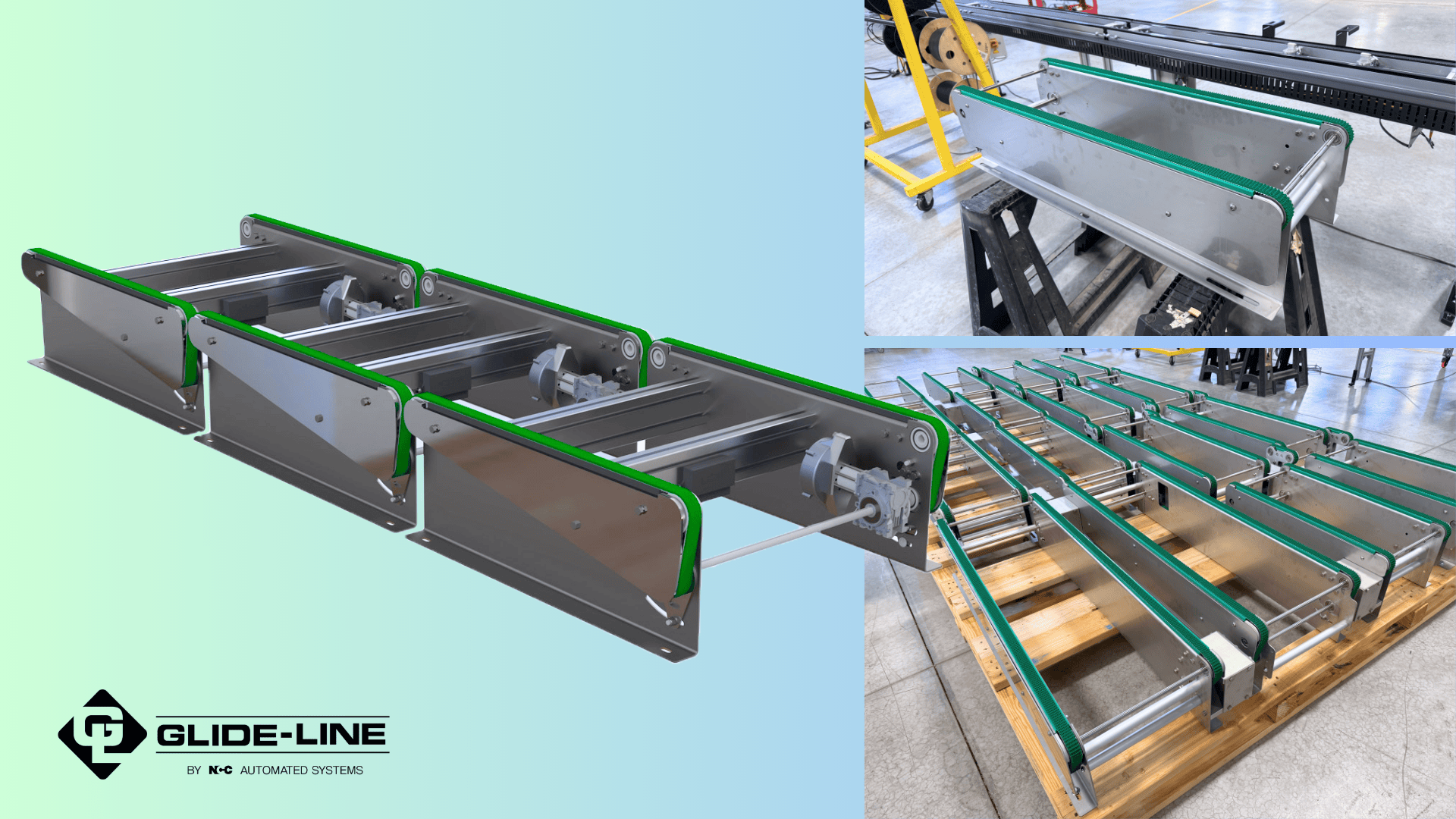

Glide-Line Unveils Custom-Engineered Zero Contact Zoned Conveyor for Heavy-Duty Applications

Videos

Glide Line Pallet Conveyor Demonstration at Automate Expo

Read More… from Glide Line Pallet Conveyor Demonstration at Automate Expo

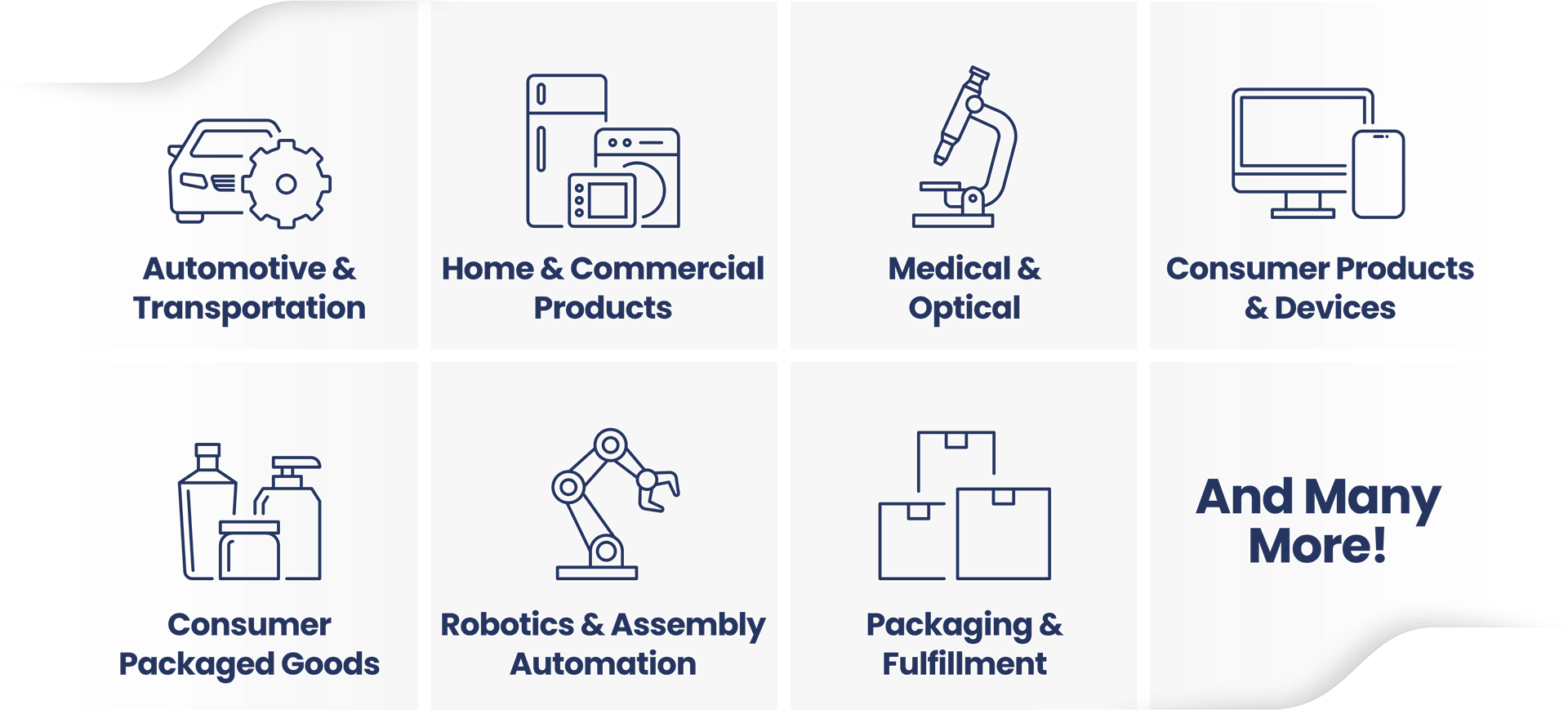

Empowering These Industries

We provide precise, efficient, and reliable material handling tailored to the unique demands of virtually any manufacturing or assembly environment, ensuring optimized flow and productivity wherever products need to move.

Empowering These Industries

We provide precise, efficient, and reliable material handling tailored to the unique demands of virtually any manufacturing or assembly environment, ensuring optimized flow and productivity wherever products need to move.

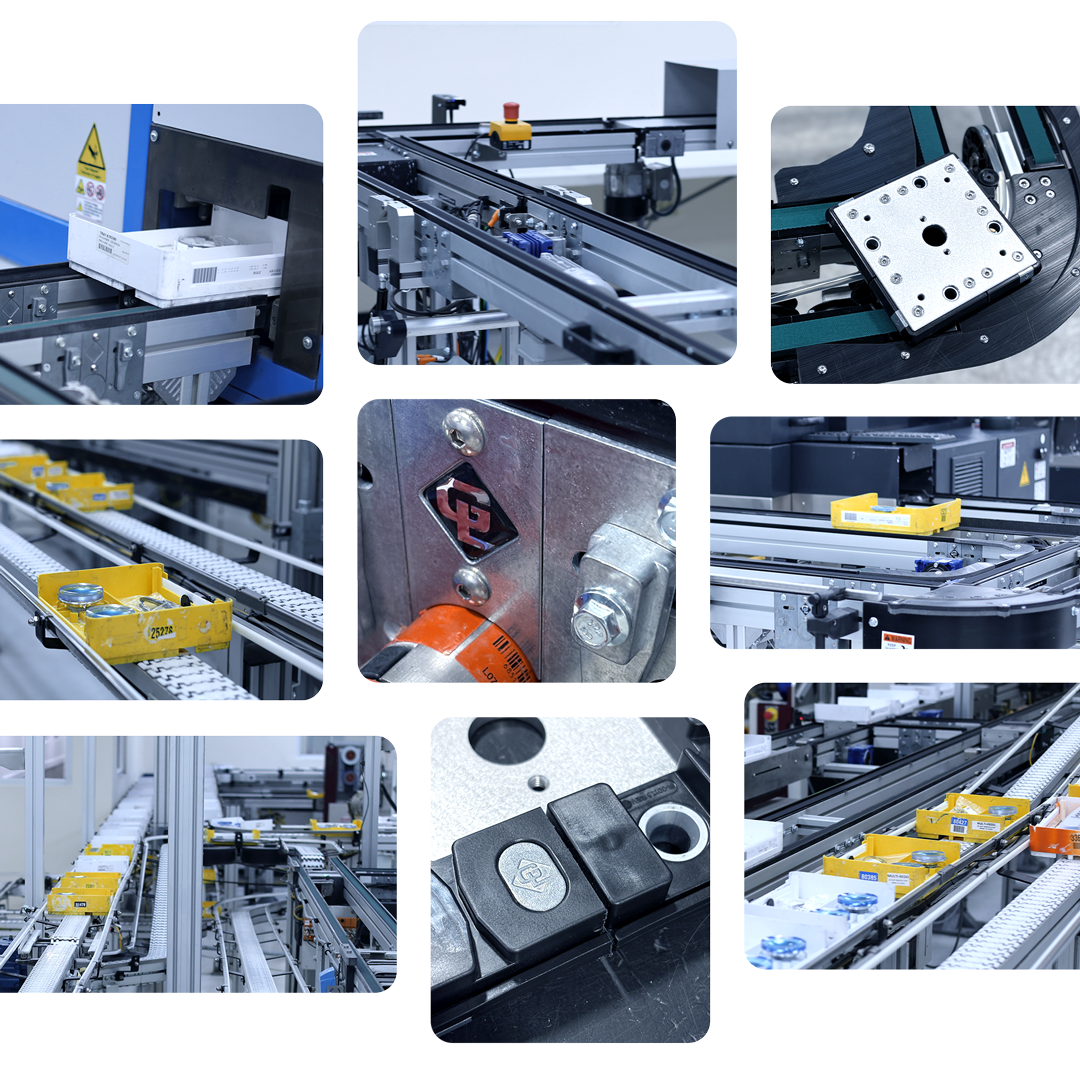

See our full portfolio

We offer modular solutions for all your automation needs. From single strand conveyors to fully integrated systems, we can support your every industrial automation need.

See our full portfolio

We offer modular solutions for all your automation needs. From single strand conveyors to fully integrated systems, we can support your every industrial automation need.

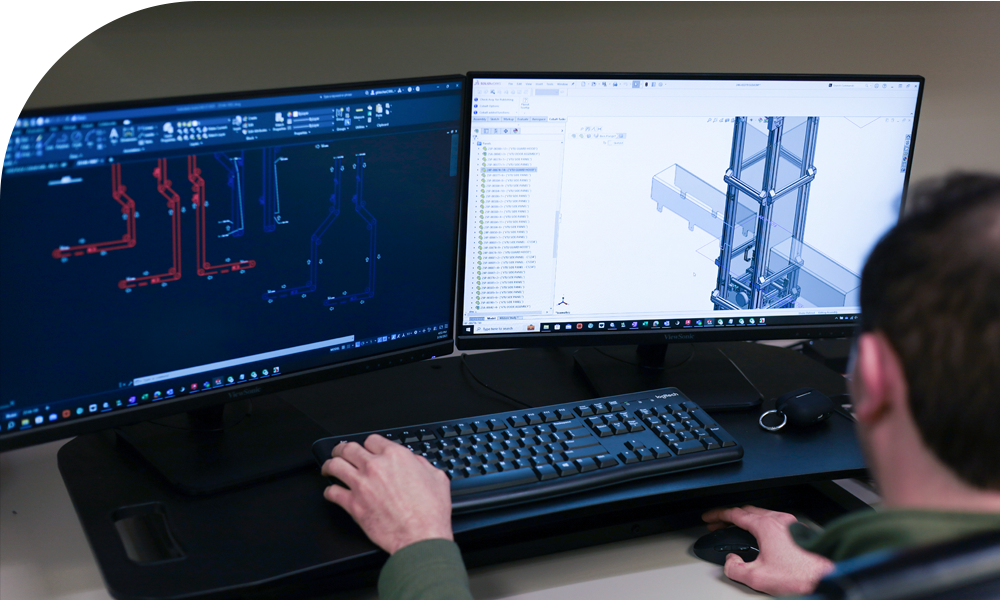

IMPACT! is our in-context, Solidworks-based Configurator for instant pricing and part numbers

IMPACT! is a Solidworks and Excel integration. Use Excel for application details and capacity feedback, as well as instant part numbers and pricing. Click a button to insert accurate CAD models directly into Solidworks, always real time linked to Excel. Your master assembly matches your Excel bill of material, pricing, and models – all in sync, all the time.

Your needs change, no problem – all models are highly configurable, not to mention include motion states and are configured for snap-to mating.

IMPACT! is our in-context, Solidworks-based Configurator for instant pricing and part numbers

MPACT! is a Solidworks and Excel integration. Use Excel for application details and capacity feedback, as well as instant part numbers and pricing. Click a button to insert accurate CAD models directly into Solidworks, always real time linked to Excel. Your master assembly matches your Excel bill of material, pricing, and models – all in sync, all the time.

Your needs change, no problem – all models are highly configurable, not to mention include motion states and are configured for snap-to mating.

Visit our resource library

To check out our wide range of educational resources. From demo videos to eBooks on solving design challenges, we hope these tools help. If you can’t find an answer to your question please contact us.

Ready to get started with a Better Flexible Manufacturer for Conveyor Systems?

Visit our resource library

To check out our wide range of educational resources. From demo videos to eBooks on solving design challenges, we hope these tools help. If you can’t find an answer to your question please contact us.

Ready to get started with a Better Flexible Manufacturer for Conveyor Systems?