Conveyor System Terminlogy

Glide-Line offers a full range of customizable conveyor systems designed to improve automation, flexibility, and efficiency. Their product lineup includes precision timing belt conveyors in single-, dual-, and multi-strand configurations for accurate, repeatable motion; durable roller chain conveyors for heavy-duty applications; and intelligent zero-contact zoned conveyors that prevent product collisions. They also provide FlexMove modular conveyors for curves, spirals, and elevation changes, the versatile Glide-Line 360 for complex multi-directional motion, and innovative Vertical Transport Units (VTUs) for smooth vertical transfers. In addition, Glide-Line develops custom conveyor solutions tailored to unique manufacturing challenges, ensuring seamless integration with any automated system.

Timing Belt Conveyors

Single-Strand Solutions

What is a single strand conveyor?

A highly configurable timing-belt conveyor in a single strand configuration, designed for precision indexing, durability and clean-room use.

How it works

Products or pallets ride on a T5 (or similar) toothed timing belt driven by a pulley/drive unit. The belt’s teeth engage positive drive, so there is no belt-slip, allowing accurate positioning for indexing, pick & place or inspection operations. The conveyor uses precision bearings, clean-room rated components (down to ISO Class 5) and 24 VDC or AC motors. Because the drive is positive, the system can move to exact positions and hold them.

Features / Use-cases

Max speed ~66.70 m/min, up to ~250 lb capacity, belt width ~1″, aluminium-extrusion frame. Suited for feeder industry, clean-rooms, precision automation.

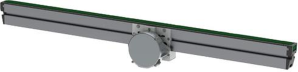

Dual-Strand Solutions

What is a dual strand conveyor?

A timing belt conveyor featuring two parallel strands, used primarily for handling larger platform-type fixtures or work-piece pallets.

How it works

Two (or more) separate timing belt strands run side by side. Each strand carries part of the load. The dual-strand structure distributes weight and supports large fixtures moving from workstation to workstation. The drive system uses standard timing-belt technologies, but because of the dual strands, the system can handle larger loads or wider pallets.

Features / Use-cases

Speeds 3.5-70 m/min (with 1750 rpm motor), transport payload ~250 lb per strand. Belt type: 25 mm wide polyurethane core T5 timing belt with steel tension members. Extruded aluminium construction. Clean-room, antistatic options.

Multi-Strand Solutions

What is a multi-strand conveyor?

A timing belt conveyor system with multiple parallel strands (three, four, or more) to handle very wide or heavy loads (e.g., large panels).

How it works

Similar to dual-strand but expanded: multiple belt strands side-by-side share the load and provide a broad conveying surface. The T5 timing style belts provide positive drive across each strand. The distributed load reduces stress per belt and supports large panel-type products or fixtures. It integrates with transfer units (e.g., the Roller Lift Transfer Unit) for flexibility.

Features / Use-cases

Large, direct product-handling of wide panels. Clean-room certified or antistatic options available.

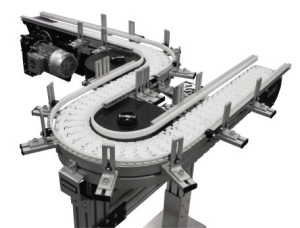

Curve Conveyor (within Timing Belt family)

What is a curve conveyor?

A curved version of the timing belt conveyor, allowing direction changes within a conveyor system while still maintaining precision indexing and positive belt drive.

How it works

The timing belt modulated system is arranged around curved or arc sections, with pulleys or idlers creating the required path. Because the belt is toothed and positively engaged, the system can maintain accuracy even in curves — allowing pallets or fixtures to turn direction without loss of indexing or alignment. (While a specific dedicated page isn’t cited, it’s listed in the navigation for Timing Belt Conveyors.)

Features / Use-cases

Useful where layout requires curved routing (e.g., around workstations, tight factory footprints) while retaining precision.

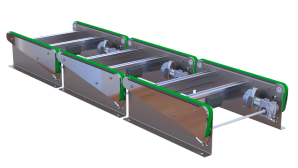

Roller Chain Conveyors

What is a roller chain conveyor?

A heavy-duty conveyor solution using roller chain as the conveying medium (rather than purely belt), designed for large loads, heavy fixtures, long runs, heavy accumulation, and flexible configuration.

How it works

A roller chain (heat-treated steel links) drives polymer-carrying rollers which support the pallet or product. The chain drives the rollers, the rollers carry the product. Because the rollers spin freely (less friction), there’s capacity for accumulation/back-pressure relief. A single drive can power long runs thanks to the chain durability. The system is modular and configurable to width/length.

Features / Use-cases

High-capacity load (up to ~700 kg accumulated load in certain versions) for heavy assemblies like appliances, automotive parts, furniture. The combination of chain drive + rollers gives ruggedness and flexibility while maintaining modularity.

Zero Contact Zoned Conveyor

What is a Zero Contact Zoned Conveyor?:

A conveyor system composed of independently controlled zones that transport products without ever allowing product-to-product contact (i.e., zero-pressure accumulation).

How it works

The conveyor is segmented into zones; each zone has its own drive (motor or 24 V brushless), sensors and logic (zero-pressure logic). When a product enters a zone, upstream zones can stop or slow, so that contact between items is avoided. The system allows accumulation without collisions. Maintenance from top, clean-room able, etc.

Features / Use-cases

Particularly valuable for delicate or heavy products where contact might cause damage, or in layout where precise spacing is required. The configurable width/length and zone logic allow more intelligent flow control in automated production lines.

FlexMove Conveyors

What is a FlexMove Conveyor?

A modular and flexible conveyor system family designed for more complex motion, elevation change, tight footprint, assemblies with unique routing (e.g., spirals, wedges, pallet loops).

How it works

Under the FlexMove umbrella are multiple specialized conveyor types:

- Alpine Conveyors: compact spiral design for elevating/lowering product in continuous flow, maximizing vertical space.

- Helix (Spiral) Conveyors: Helical curve conveyor for buffering, elevation change, compact footprint. Uses side roller chain to reduce friction.

- Wedge Elevators: Two parallel conveyor belts with a urethane side-gripper chain that “wedges” a product from the sides, enabling vertical transport (even up to 90° incline) or inversion.

- Top Running Loops & Pallet Systems: Chain circulates in a single plane (top running loop) to handle precise routing for automation/assembly cells.

Each variant uses the FlexMove modular structure: chain or belt modules, drives, supports, adjustable widths/lengths, and allows routing through curves, inclines, loops.

Features / Use-cases: Applications with space constraints, elevation changes, continuous flow buffering, pallet routing in automation cells, high flexibility in layout.

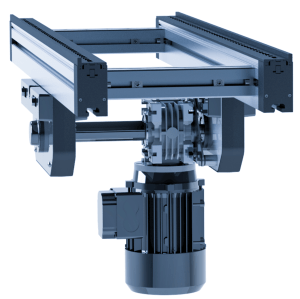

Glide-Line 360

What is the Glide-Line 360?

A highly configurable conveyor solution that can shuttle, divert, merge, sort, stack, lift/lower, transfer, turn — or any combination thereof — in one system. In effect, a conveyor-actuator hybrid designed for complex motion and automated integration.

How it works

The system uses timing-belt driven conveyors combined with actuator motion (linear or rotational). The conveyor segments themselves act as motion axes, enabling movements beyond straight transport: for example, shifting a pallet sideways, lifting it, rotating it, merging it into another loop, etc. Because it is modular and built with 24 V DC brushless motors, extruded aluminium frames, standard belts etc., the 360 system can be re-configured for complex tasks while maintaining conveyor functionality. Maintenance and belt changes are top-accessible.

Features / Use-cases

Ideal for automation integrators who require more than mere transport. For example: merging flows, sorting parts to different workstations, integrating robot pick-cells where pallets need to shift axes, re-orienting parts, or compact work-cells with multi-axis conveyor motion.

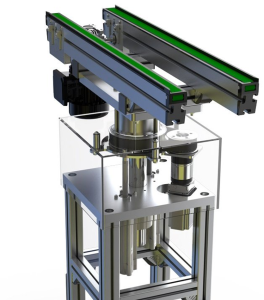

Vertical Transport Unit (VTU)

What is a Vertical Transport unit?

A conveyor module designed to move products vertically (up/down) between levels, decks or locations — often within the footprint of a station or machine cell. Includes multiple variants: Dual Axis VTU, Dual Deck VTU, Low-Cost Mini VTU, Tilting Deck VTU, Multiple Position VTU, Pass-Through VTU, Bypass Lift VTU, Rack Feeder, Machine-Tending Solutions.

How it works

The VTU uses a lift mechanism (servo, stepper, pneumatic or motorized) to raise or lower the product. For example, a dual-deck VTU has two transport decks that move simultaneously – one deck goes up while the other goes down – enabling continuous flow. Other configurations allow tilting of the deck (for robot access), bypass of the main line while work is done, or storage/feed functions (rack feeder). The transport decks themselves can be conveyors (timing belt or other) and integrate seamlessly into the line.

Features / Use-cases

Useful when elevating or lowering parts between production levels, integrating vertical buffer zones, machine-tending where parts must travel up/down to robot cells, or where vertical indexing/tilting is required.

Drop & Rotate Transfer Unit (DART)

What is a Drop & Rotate Transfer unit?

A Drop and Rotate Transfer Unit (often seen under brand names like DART) is a specialized material handling device used in automated conveyor systems to precisely change the direction and/or orientation of a product or pallet.

How it works

The process begins when a product on a pallet is indexed and lifted off the main conveyor surface by an internal mechanism, usually driven pneumatically. While suspended, a servo-driven rotating deck precisely spins the pallet to the desired angle (e.g. for a perpendicular transfer or for a turn-around). Once the new orientation is achieved and aligned with the destination conveyor line, the unit lowers the pallet back down, transferring it onto the belts of the secondary line. This sequence of lifting, rotating, and lowering enables complex traffic control, streamlines product orientation changes, and maximizes layout flexibility.

Features / Use-cases

Complex Traffic Control: It acts as a centralized “hub” to manage complex material flow, distributing work pieces to multiple downstream conveyor lines.

Orientation Control: It can be used to re-orient a product for processes like assembly, inspection, or packaging—for example, rotating a car part for a robot to access a new side.

Space Saving: By combining lifting, rotating, and transferring functions into a single compact unit, it can simplify factory layouts and save significant floor space compared to using multiple separate devices (like a turntable and a separate transfer unit).

Precision: These units often use servo-driven rotation for smooth, rapid, and precise positioning, which is critical for automated processes.

Cost-Effectiveness: For complex layouts, it can often be a more cost-effective solution than using a series of typical lift and transfer units.

Customized Solutions

What are customized conveyor solutions?

A class of conveyor solutions built for specific bespoke applications. Examples include: Centerline Adjustable Conveyor, Conveyor Rotate Unit, Direct Product Handling Conveyor, Drop & Rotate Transfer Unit, Dual Pop-Up Transfer, FlexMove Line Integration, Pedestal Mounting Support System, Pop-Up Right Angle Transfer, Serpentine Buffer Conveyor, Slave Driven Conveyor, Transfer Bridge Conveyor Solution.

How they work

These solutions build on the core conveyor technologies (timing belt, chain, etc.) but add custom features or mechanisms to solve non-standard applications. For example:

- Slave Driven Conveyor: One motor drives multiple conveyors via mechanical PTO/chain drives, reducing motor count and cost.

- Transfer Bridge Conveyor Solution: A supplemental conveyor designed to handle end-to-end transfers, supporting heavy/large products (e.g., automotive tires) with special frame, end-drive, and belt material.

- Others like rotate units, pop-up transfers, serpentine buffers, etc., provide specialized motion or buffering beyond standard straight conveyors.

Features / Use-cases: Ideal when the standard conveyor families don’t directly address the application (very heavy loads, unusual layout, multi-axis transfers, special product handling). These allow integrators to leverage Glide-Line’s configurable modules but tailor them further.

Ready to get started

with a Better Flexible Manufacturer for Conveyor Systems?