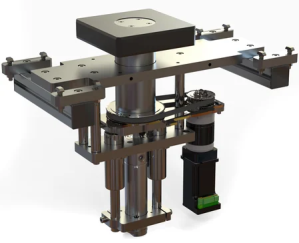

Lift & Rotate Unit

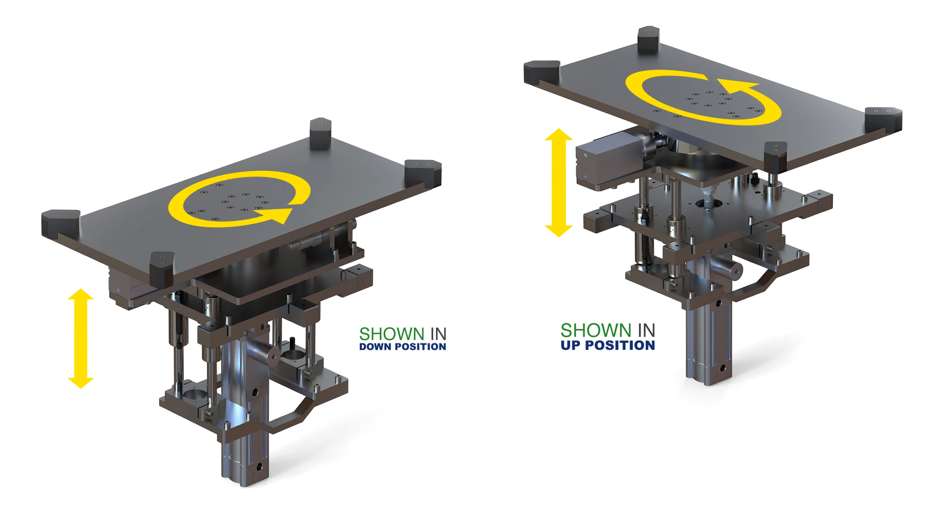

Lift & Bypass Capabilities

The Pneumatic Lift Rotate unit is designed to turn pallets 90° or 180° in a clockwise or counterclockwise direction. The unit uses pneumatics (lift portion) and servo motors (rotating portion) for ultra-smooth rotational motion and acceleration. Servo motors are customizable for special applications that demand continuous rotational motion, such as winding operations or visual inspection requiring multiple view angles. It can also act as a lift-and-bypass unit, lifting pallets and placing them on a shelf so other pallets can pass through.

Specifications

- Bi-directional operation

- Payload capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm – 1040mm in 1mm increments

- Pallet width range – 160mm – 1040mm in 1mm increments

- 40mm bore lift cylinder

- Lift Stroke of 1.5-40mm

- ¼ NPT ports

Features

- Pneumatic lift

- Servo driven rotation

- Integrated shock absorbers for lift motion

Options

- Guard package

- High tolerance locating pins available

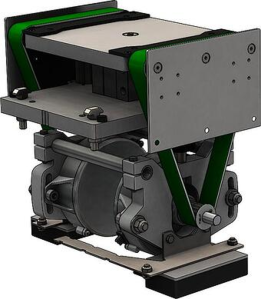

Manual Lift & Rotate Unit

Rotate Product Without Controls

Allows for vertical lifting of pallet and rotation of 90 degrees.

- Rotation lock to secure pallet in position at end of rotation cycle

- Robust Lift and Rotate Unit that allows for product to be lifted off conveyor, and rotated 90 degrees

- Provides operator improved access to product

- Manual rotation allows for operator to rotate product without controls

Videos

Features

- Dual acting air cylinder with clamping device to secure device in case of loss of air pressure

- Robust slewing bearing for rotation ensures smooth and easy operation

Options

- Can be designed for various rotation angles or freely spinning.

Downloads

Lift & Rotate Unit

Lift & Bypass Capabilities

The Pneumatic Lift Rotate unit is designed to turn pallets 90° or 180° in a clockwise or counterclockwise direction. The unit uses pneumatics (lift portion) and servo motors (rotating portion) for ultra-smooth rotational motion and acceleration. Servo motors are customizable for special applications that demand continuous rotational motion, such as winding operations or visual inspection requiring multiple view angles. It can also act as a lift-and-bypass unit, lifting pallets and placing them on a shelf so other pallets can pass through.

Specifications

- Bi-directional operation

- Payload capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm – 1040mm in 1mm increments

- Pallet width range – 160mm – 1040mm in 1mm increments

- 40mm bore lift cylinder

- Lift Stroke of 1.5-40mm

- ¼ NPT ports

Features

- Pneumatic lift

- Servo driven rotation

- Integrated shock absorbers for lift motion

Options

- Guard package

- High tolerance locating pins available

Manual Lift & Rotate Unit

Rotate Product Without Controls

Allows for vertical lifting of pallet and rotation of 90 degrees.

- Rotation lock to secure pallet in position at end of rotation cycle

- Robust Lift and Rotate Unit that allows for product to be lifted off conveyor, and rotated 90 degrees

- Provides operator improved access to product

- Manual rotation allows for operator to rotate product without controls

Features

- Dual acting air cylinder with clamping device to secure device in case of loss of air pressure

- Robust slewing bearing for rotation ensures smooth and easy operation

Options

- Can be designed for various rotation angles or freely spinning.