How Glide-Line’s AMR/AGV Conveyor Toppers Transform Material Handling for Mobile Robots

In today’s manufacturing and warehousing operations, autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are redefining how materials move. They handle transport tasks efficiently — but transferring products on and off those robots remains a challenge.

Enter Glide-Line’s AMR/AGV conveyor toppers — purpose-built solutions that bridge this gap. If you’re an integrator or plant engineer looking to maximize throughput, reduce downtime, and future-proof your line layout, this innovation changes the game.

The Challenge with AMRs and Product Transfer

While AMRs excel at navigation and payload delivery, they often encounter performance bottlenecks at transfer points.

- Traditional conveyors are heavy, rigid, and poorly suited for mobile bases.

- Result: wasted time, frequent maintenance, and under-performing ROI on your AMR investment.

The key is designing a topper conveyor that complements the robot’s agility — lightweight, configurable, and seamlessly integrated with existing production lines.

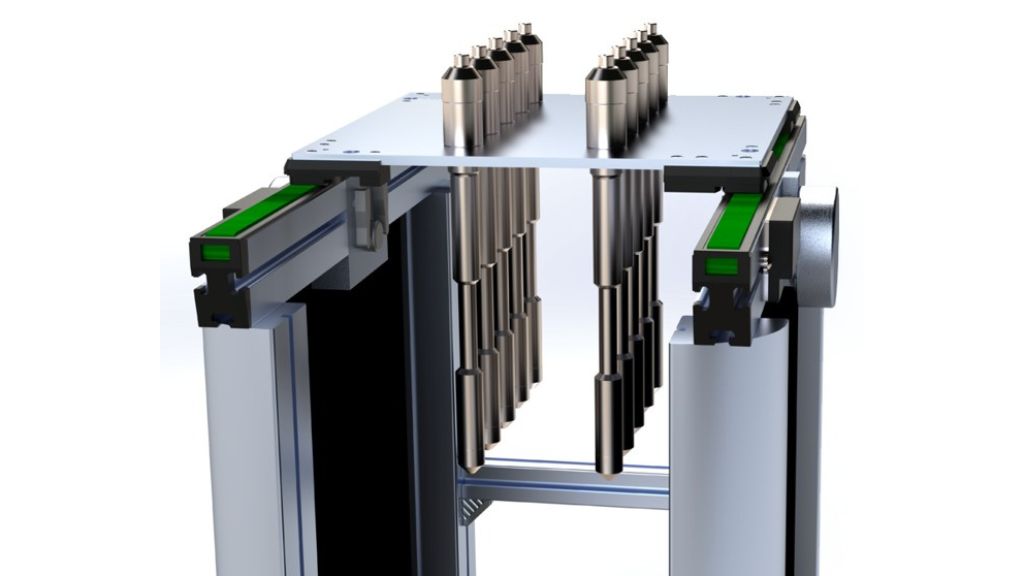

What Makes Glide-Line’s AMR/AGV Conveyor Solutions Different

Glide-Line’s toppers are engineered to support real-world production needs — not just robotic novelty.

✅ Lightweight Efficiency:

Constructed with precision aluminum framing and DC drives, Glide-Line toppers minimize battery drain and extend AMR uptime.

✅ Custom Configurability (Without Custom Cost):

Each topper is configurable to your product, load, and layout — from open-center designs to tight-transfer overlapping strands or rotating platforms.

✅ Fast Lead Times:

Glide-Line’s modular design platform turns “custom” into “standard,” delivering tailor-made conveyors without long waits or high engineering costs.

✅ Seamless System Integration:

Topper designs work effortlessly with Glide-Line’s pallet handling, multi-strand, and timing belt conveyors — creating a continuous, flexible material flow across your plant.

The Real-World Benefits of AMR Conveyor Integration

When paired with a Glide-Line topper, an AMR or AGV becomes more than a transporter — it becomes a production asset.

- Higher Throughput: Continuous, automated transfers between workstations eliminate manual handoffs.

- Reduced Cycle Time: Smart transfer geometry speeds up material flow, keeping every station active.

- Battery & Payload Optimization: Lightweight frames increase payload and runtime per charge.

- Future Flexibility: Need to change layouts or product types? Modular toppers adapt instantly.

- Lower Cost of Ownership: Glide-Line’s “custom-standard” model reduces rework, downtime, and maintenance costs.

💡 Tip: Integrators can use the Glide-Line IMPACT! Configurator to instantly model AMR toppers for specific robots, complete with CAD data and part numbers.

Integration Tips for System Designers

If you’re specifying an AMR conveyor topper, consider these key points during design:

- Interface Geometry: Match the topper’s strands to the fixed conveyor line for smooth product transfer.

- Battery Budget: Account for topper weight plus product load to ensure optimal performance.

- Motion Requirements: Choose toppers with lift, rotate, or tilt functionality if product orientation matters.

- Frame Design: Open frames for lightweight, clean applications; enclosed frames for heavier or dusty environments.

- Software Integration: Use robot control signals for automated hand-off and line coordination.

Each of these variables is easily configurable within Glide-Line’s modular design framework.

Why It Matters Now

With industries pushing toward “lights-out” manufacturing and flexible automation, integrating AMRs is no longer optional — it’s essential.

However, many projects fail to reach full potential due to inefficient product transfers.

By equipping AMRs with Glide-Line conveyor toppers, manufacturers unlock:

- Seamless connectivity between production islands

- Real-time adaptability for mixed product lines

- A scalable path to full automation

Maximize Your AMR’s True Potential

Don’t let the hand-off point be your automation’s weak link. Glide-Line’s AMR/AGV conveyor toppers eliminate transfer bottlenecks, increase efficiency, and make your robots work smarter.