Smooth Conveyor Transfer for Delicate Photovoltaic Cells and Solar Panels

Every stage in the photovoltaic cell and solar panel manufacturing process requires delicate product handling techniques. Any cracks on the surface of a photovoltaic cell will influence the module’s efficiency and may render an individual cell completely useless.

As protective layers are only applied after the chemical texturing, coating, curing, and soldering (stringing) of silicon wafers, damage to the photovoltaic cells can occur during every step of the solar panel’s manufacturing cycle. A gentle conveyor solution can help prevent damage while efficiently moving cells and panels through different production stages.

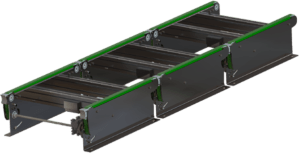

Glide-Line’s zero contact zoned conveyors eliminate product-to-product collisions on the line, while our transfer solutions gently orient and hand off products to different process stations. Consider these solutions from Glide-Line for your production lines to reduce manual handling of PV cells and solar modules that could lead to higher reject rates.

Maintain Quality and Reduce Damage with Zero Contact Zoned Conveyors and Gentle Transfers

The Zero Contact Zoned Conveyor controls each PV cell or solar panel independently on the line. Products only move within a defined zone with controllers operating sequentially to prevent collisions during accumulation.

With this design, the conveyor delivers:

- Gentle product movement with zero collisions that could damage your delicate PV cells or solar panels

- Increased energy efficiency as each section of the conveyor only “runs on demand” when upstream processes complete

- Zero backpressure from the conveyor while products accumulate on the line to improve the usable life of the belt

The all-urethane white belt provides friction to gently move products directly on the line without scratching or damaging items during stops and starts. An open-center design gives you access to the bottom of the cells or panels when required. Combined with these features, the system uses 24v DC drives to expertly control movements without requiring VFDs.

Additionally, you can configure the multi-strand timing belt conveyors to adjust the width when changing direction to maintain the required orientation. For PV cells, you can design a solution with guides to provide stability while for panels, you can increase the number of strands for improved rigidity and support across the conveyor line. We’ve found that oftentimes the edges of the panels are delicate and cannot come into contact with our standard side guides, so accommodations should be made by either Glide-Line or the integrator.

Transfer Solutions for Delicate Photovoltaic Cells and Solar Panels/Modules

When accumulating products on the line, Glide-Line has solutions for vertical transfers, right-angle direction changes, traffic control sections, and 360° rotation units.

PV Cell and Solar Panel Transfer Solutions for Every Application

Managing transfers between different conveyors is possible with customizable and configurable solutions from Glide-Line. Because of the modular design, you can integrate these solutions at any point in the production line to streamline your automated product handling solution for greater efficiency, reduced damage, and precise control.

With Glide-Line’s solutions, you can:

- Reduce damage during conveyor-to-conveyor transfers with a lift and rotate unit without increasing the footprint of the system

- Move photovoltaic cells up or down with a vertical transfer unit to hand off to another conveyor or access a storage area

- Merge or shuttle different products between conveyors and process stages while controlling traffic, diverting items, or stacking completed modules

With Glide-Line, the configuration possibilities are endless and because all our solutions are modular, you can fit them into your existing facility.

Choose Glide-Line for Your Automated Photovoltaic Cell and Solar Panel Production Process

All of Glide-Line’s solutions are documented with 3D models with each proposal, allowing you to order any replacement part that may lead to extended downtimes common with customized systems. Our engineers can assist with developing a solution that will solve your unique application challenges, eliminate contact between products, and deliver the ROI you expect from a PV cell and solar panel conveyor.

With our in-context IMPACT! configurator, you can design your solution in SolidWorks and generate an accurate quote in record time.

To discuss your requirements and see how Glide-Line can deliver a PV cell and solar panel handling conveyor, contact us today.