The Pre-Assembled Advantage: Why Integrators Profit More with Glide-Line

When engineers and project managers evaluate conveyor systems, they typically weigh specs, flexibility, and price. What often gets overlooked are the hidden costs of assembly — time, labor, and tools required after the conveyors arrive on-site. At Glide-Line, we approach this differently. We offer a range of assembly options designed to match your project’s needs, giving you the choice between efficiency and flexibility.

1. The Value of Pre-Assembled Conveyors

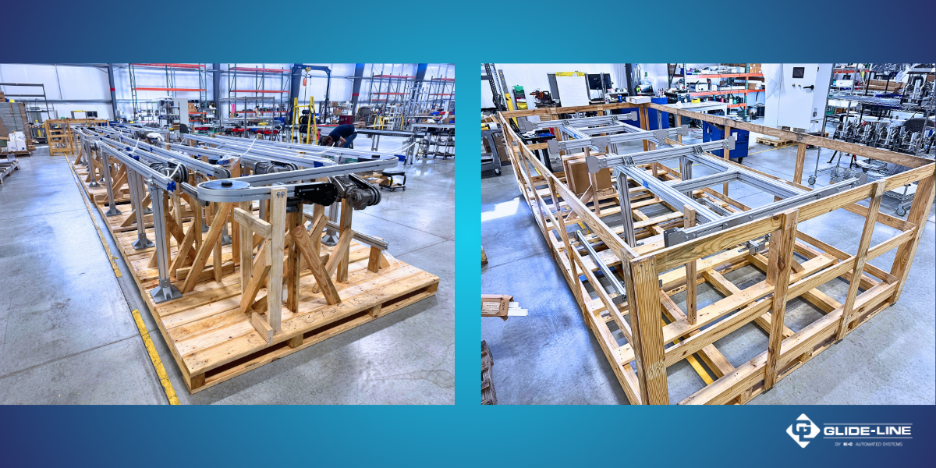

Our pre-assembled option is a unique value proposition that many competitors simply don’t offer. When you choose this path, Glide-Line pre-assembles and packages your conveyors before shipping. Integrators who opt in consistently save time, resources, and labor costs — freeing their teams to focus on higher-value work that drives profit.

This isn’t just theory. Many major automation companies have seen direct benefits from this approach. One of the deciding factors in their purchase was Glide-Line’s ability to deliver conveyors already assembled. For busy engineering and integration teams, the ability to receive conveyors that are ready to install is a major competitive advantage.

2. Flexible Options to Fit Your Needs

Glide-Line’s offering isn’t one-size-fits-all. We provide multiple levels of pre-assembly so customers can choose what works best:

- Standard Assembly: Conveyors, stands, and modules are built and shipped separately. Customers simply attach stands and mount devices to the conveyors in their designated locations.

- Fully Pre-Assembled: Conveyors arrive with stands and devices already mounted. This option is as close to “plug-and-play” as possible — a true time saver for integrators.

- Future Options in Development: We are actively exploring fully pre-assembled, tested, and wired systems — including pneumatics and PLC controls. This custom advanced service, would allow Glide-Line to test full conveyor lines before they leave our facility, with support from our technicians on-site as needed.

3. How Glide-Line’s Pre-Assembly Compares to Bosch’s Part-Based Model

Many conveyor suppliers follow a part-based model. For example, Bosch typically sells conveyors as separate part numbers: the drive assembly, the return or tail, and the frame all ship individually. Belting material is also sold in rolls, which means customers must cut and weld belts themselves — often requiring additional tools like a belt welding kit.

This approach leaves integrators with the responsibility to assemble conveyors on-site, adding time, labor, and hidden costs to a project. For some, this can be manageable, but for busy integrators it can become a bottleneck that impacts delivery schedules and profitability.

Glide-Line takes a different approach. Our standard option ships conveyors with stands and modules separately, but already built and packaged to minimize the customer’s assembly workload. And for teams who want a turnkey experience, our fully pre-assembled option provides plug-and-play conveyors with stands, devices, and modules mounted in place — ready to install, wire, and run.

By offering flexible levels of assembly, Glide-Line helps integrators control costs and eliminate the inefficiencies that come with piecemeal conveyor systems.

4. The Bottom Line: Profitability Through Flexibility

At Glide-Line, we bring bespoke conveyor solutions to life, offering comprehensive service and assembly options tailored to each customer’s unique requirements. More and more integrators are realizing that their teams don’t generate profit by unpacking boxes and piecing together parts — they generate profit by delivering high-value expertise in areas like controls, system design, and integration strategy.

That’s where our pre-assembly options create measurable advantage. By letting Glide-Line handle the hard work of assembly — whether partially built or fully plug-and-play — integrators save time, reduce hidden costs, and free their resources to focus on what truly matters: delivering smarter, more profitable automation solutions.

Why receive conveyors in pieces when you can receive them pre-assembled and ready to perform? Let us take care of the assembly so you can put your best talent where it counts.

Interested in exploring pre-assembled conveyor options for your next project? Contact us today at info@glide-line.com.