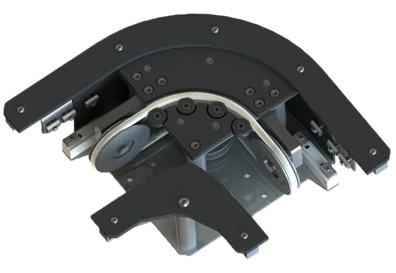

Curve Conveyor

Smooth Pallet Curving

Glide-Line curves are a mechanism to change the direction of a pallet. Pallets are conveyed around the curves by means of a solid, round urethane belt that is driven on v-groove pulleys. Small idler pulleys follow the track to reduce friction and prevent wear and tear.

Due to the configurable nature of our systems, curves can be configured as options of 30, 45, 60, 90, and 180 degrees, other custom options are available upon request.

Tandem Curves:

One variation of a curve is a Tandem Curve which allow pallets to transfer to/from parallel conveyor lanes, maintaining the leading edge of the pallet as it travels. The unit provides an economical approach to lane transfers, and if slaved can save several drives required for a traditional solution. Gap between parallel conveyors can range between 45mm and 350mm in 1mm increments.

Videos

Specifications

- Curves are suitable for pallets with 1.5:1 length to width ratio

- Curves are suitable for pallets that are up to 400mm x 400mm

- Curves are suitable for loads up to 44 lbs (20 kg)

Features

Curves are typically slave driven off adjacent conveyor by extending the o-ring belt into the upstream or downstream conveyor. The upstream conveyor utilizes a power take off shaft through a secondary drive box on the main conveyor and this shaft drives the v-grooved o-ring belt pulley.

Options

- Self-powered curve options available upon request

- Various angles to suit your needs, configurable from 15 to 270 degrees

Curve Conveyor

Smooth Pallet Curving

Glide-Line curves are a mechanism to change the direction of a pallet. Pallets are conveyed around the curves by means of a solid, round urethane belt that is driven on v-groove pulleys. Small idler pulleys follow the track to reduce friction and prevent wear and tear.

Due to the configurable nature of our systems, curves can be configured as options of 30, 45, 60, 90, and 180 degrees, other custom options are available upon request.

Tandem Curves:

One variation of a curve is a Tandem Curve which allow pallets to transfer to/from parallel conveyor lanes, maintaining the leading edge of the pallet as it travels. The unit provides an economical approach to lane transfers, and if slaved can save several drives required for a traditional solution. Gap between parallel conveyors can range between 45mm and 350mm in 1mm increments.

Specifications

- Curves are suitable for pallets with 1.5:1 length to width ratio

- Curves are suitable for pallets that are up to 400mm x 400mm

- Curves are suitable for loads up to 44 lbs (20 kg)

Features

Curves are typically slave driven off adjacent conveyor by extending the o-ring belt into the upstream or downstream conveyor. The upstream conveyor utilizes a power take off shaft through a secondary drive box on the main conveyor and this shaft drives the v-grooved o-ring belt pulley.

Options

- Self-powered curve options available upon request

- Various angles to suit your needs, configurable from 15 to 270 degrees