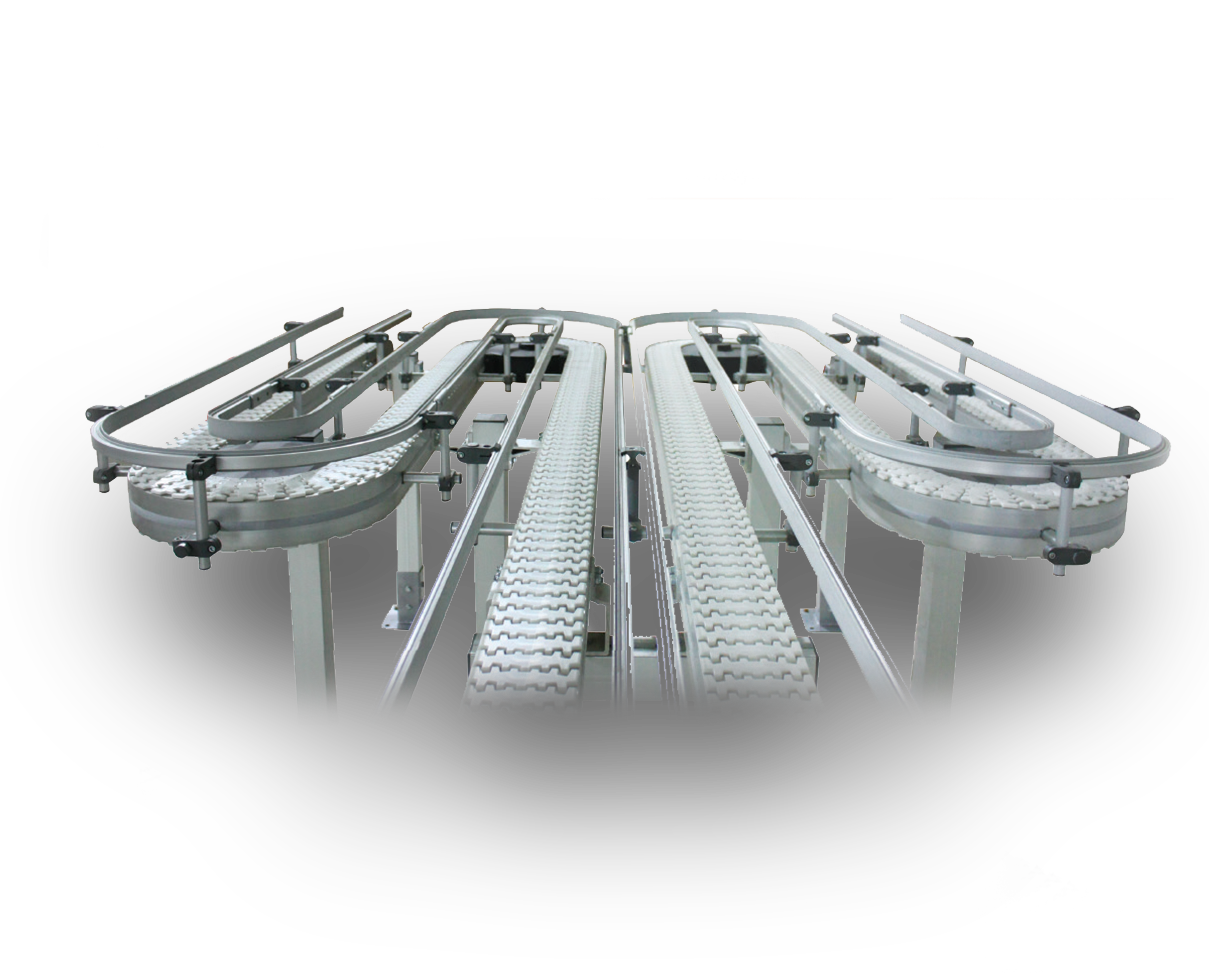

Seamless FlexMove Chain Integration with Glide-Line Timing Belt Systems

Integrate FlexMove with our TLTU, VTU and More!

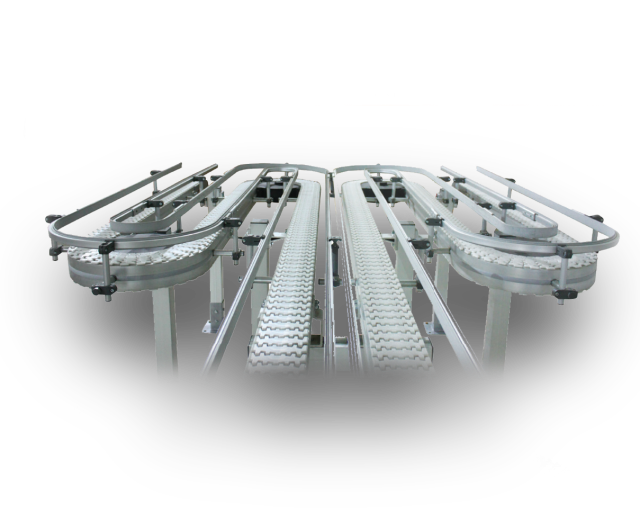

FlexMove Standard Conveyors are a versatile and efficient solution for material handling needs across a variety of industries. These modular and flexible conveyor systems are designed to navigate tight turns and inclines, making them ideal for complex layouts and space-constrained environments.

The modularity of our FlexMove conveyors allow us to directly integrate into our Glide-Line 360 line of products as well as other existing conveyor lines!

Videos

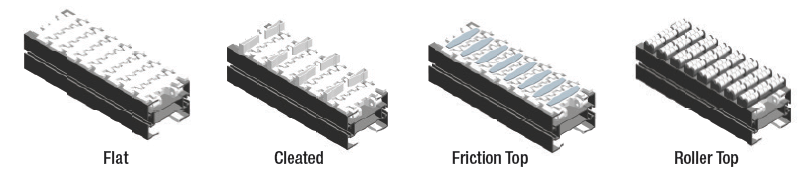

Plastic Chain Tabs

Modules

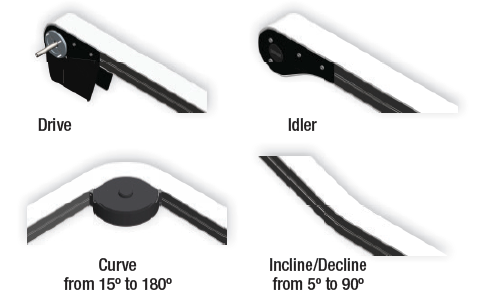

Transfers

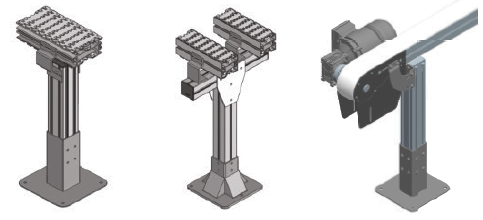

Support Stands

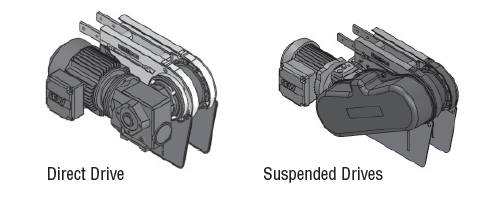

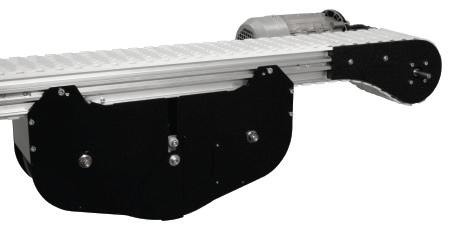

Drives

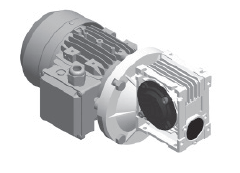

Standard / Heavy Load Gear Motors

Features

- Up to 272 kgs (600 lbs)

- Up to 76 meters (250 feet) per minute

- 45 mm, 65 mm, 85 mm, 105 mm, 150 mm, 180 mm & 260 mm (1.7, 2.5, 3, 4, 6, 7 and 10 in) widths

- 0.6 m to 29.8 m (2 to 98 ft) lengths

View our endless configurations:

Alpine Conveyors

Elevated Conveying

The FlexMove Alpine Conveyor is a highly specialized and space-saving solution for elevating, lowering, and accumulating products in a continuous flow. Its distinctive compact spiral design, reminiscent of a mountain switchback, allows it to efficiently utilize vertical space, making it an ideal choice for facilities with limited floor area.

Helix Conveyors

Smaller Footprint

The FlexMove Spiral Conveyor is a highly specialized and space-saving solution for elevating or lowering products in a continuous flow. Like its Alpine counterpart, the Spiral conveyor is designed with a compact, helical curve that maximizes vertical space, making it an ideal choice for facilities with limited floor area.

This type of conveyor excels at creating a buffer zone for accumulation, allowing for product cooling, drying, or simply balancing the flow between machines with different operating speeds. Its patented side roller chain reduces friction, enabling faster speeds and smooth product handling. With a variety of configurations and the ability to have the infeed and outfeed at any height or angle, the FlexMove Spiral conveyor provides a highly flexible and efficient way to manage product flow and optimize factory layouts.

Wedge Conveyors

Specialty Chained Side Gripped Elevation

The FlexMove Wedge Elevator is a unique and highly effective solution for vertical product transport, designed to save valuable floor space. It operates by utilizing two parallel conveyor belts with a special urethane gripper chain that gently but firmly “wedges” the sides of a product. This allows the system to lift or lower items vertically at inclines up to 90 degrees, often over aisles or to connect different production levels. The wedge elevator’s rapid transfer rate makes it ideal for continuous, high-capacity operations like packaging and bottling lines, where it can also be used for applications such as inverting products for inspection or de-pucking.

Videos

Top Running Loops & Pallet Systems

Accurate Routing

The FlexMove Top Running Loops & Pallet Systems represent a specialized and highly precise segment of the FlexMove product line, designed for applications requiring accurate product handling and routing. These systems utilize a top-running loop design where the chain circulates continuously in a single plane, which is especially beneficial for small manufacturing cells, automation, and assembly processes.

Table Top Conveyors

Low Cost Material Conveying

The FlexMove Tabletop Conveyor is a highly versatile and reliable solution for handling a wide range of products, from small bottles and cans to larger cartons and cases. Characterized by its flat, smooth chain surface, this conveyor provides a stable and consistent platform for product transport. It is exceptionally well-suited for high-speed production environments, offering durability and a low-friction surface that ensures products move seamlessly with minimal risk of tipping or damage.

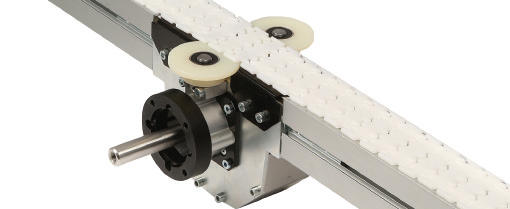

Weighted Take Up Module

Smooth Long Conveying

The FlexMove Weighted Take-Up Module is a critical component for maintaining peak performance and safety in longer FlexMove conveyor systems. It’s a simple yet highly effective device that automatically compensates for chain stretch using a weighted roller.

By providing consistent and optimal chain tension, the module prevents the chain from sagging or drooping, which eliminates the slight, jerky motion (micro-surging) that can occur on long conveyor runs. This results in smoother product handling, crucial for maintaining product integrity. The module also enhances safety by removing potential pinch points caused by loose chain. Recommended for conveyors over 40 feet in length, it’s an essential add-on for reliable, high-performance operation.

Twist Conveyors

Product Reorienting

The FlexMove Twist Conveyor is an innovative and highly efficient solution for reorienting products within a production line. Unlike other systems that require complex machinery or robotics for product rotation, the Twist conveyor uses a simple yet clever design of two independent, side-by-side conveyor chains.

As the product travels along the two chains, one is slightly elevated and angled, causing the item to gently and positively rotate. This design allows for a smooth, in-line 90-degree twist without the need for product gapping or complex guiding, significantly simplifying the manufacturing process. It is ideal for applications where access to multiple sides of a package is needed, such as for labeling, date-coding, or inspection. The Twist conveyor’s ability to handle multiple product sizes without changeover makes it a highly flexible and time-saving solution for complex packaging and assembly lines.

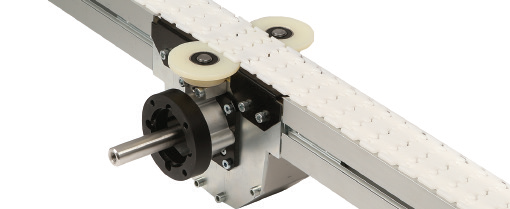

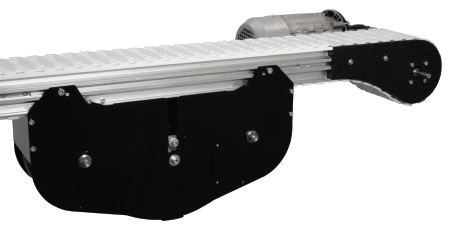

Top Running Loop Drive Design

Added Strength Driver

The FlexMove Top Running Loop Drive is a specialized and patented drive unit designed for applications where the conveyor chain forms a single, continuous loop without a return chain underneath. This design, often used in spiral, alpine, and pallet systems, is crucial for maximizing floor space and creating continuous product flow.

Unlike traditional drives that pull the chain from one end and return it underneath, the Top Running Loop Drive engages and powers the chain along its top, or product-carrying, surface. This results in a cleaner and more compact system, as there is no need for a return path. It is particularly well-suited for applications that require controlled movement, such as automated assembly, product indexing, and accumulation, as well as for multi-level systems where the conveyor needs to move products vertically with a minimal footprint. Its patented design provides superior strength, flexibility, and load-bearing capacity for demanding, continuous-loop applications.

Seamless FlexMove Chain Integration with Glide-Line Timing Belt Systems

Modular Designs

FlexMove Standard Conveyors are a versatile and efficient solution for material handling needs across a variety of industries. These modular and flexible conveyor systems are designed to navigate tight turns and inclines, making them ideal for complex layouts and space-constrained environments.

The modularity of our FlexMove conveyors allow us to directly integrate into our Glide-Line 360 line of products as well as other existing conveyor lines!

Videos

Features

- Up to 272 kgs (600 lbs)

- Up to 76 meters (250 feet) per minute

- 45 mm, 65 mm, 85 mm, 105 mm, 150 mm, 180 mm & 260 mm (1.7, 2.5, 3, 4, 6, 7 and 10 in) widths

- 0.6 m to 29.8 m (2 to 98 ft) lengths

Scroll down to view many of our endless options!

Alpine Conveyors

Elevated Conveying

The FlexMove Alpine Conveyor is a highly specialized and space-saving solution for elevating, lowering, and accumulating products in a continuous flow. Its distinctive compact spiral design, reminiscent of a mountain switchback, allows it to efficiently utilize vertical space, making it an ideal choice for facilities with limited floor area.

Helix Conveyors

Smaller Footprint

The FlexMove Spiral Conveyor is a highly specialized and space-saving solution for elevating or lowering products in a continuous flow. Like its Alpine counterpart, the Spiral conveyor is designed with a compact, helical curve that maximizes vertical space, making it an ideal choice for facilities with limited floor area.

This type of conveyor excels at creating a buffer zone for accumulation, allowing for product cooling, drying, or simply balancing the flow between machines with different operating speeds. Its patented side roller chain reduces friction, enabling faster speeds and smooth product handling. With a variety of configurations and the ability to have the infeed and outfeed at any height or angle, the FlexMove Spiral conveyor provides a highly flexible and efficient way to manage product flow and optimize factory layouts.The rotate & shuttle allows a pallet to be moved from location to another while at the same time manipulating the orientation of the pallet.

Wedge Conveyors

Specialty Chained Side Gripped Elevation

The FlexMove Wedge Elevator is a unique and highly effective solution for vertical product transport, designed to save valuable floor space. It operates by utilizing two parallel conveyor belts with a special urethane gripper chain that gently but firmly “wedges” the sides of a product. This allows the system to lift or lower items vertically at inclines up to 90 degrees, often over aisles or to connect different production levels. The wedge elevator’s rapid transfer rate makes it ideal for continuous, high-capacity operations like packaging and bottling lines, where it can also be used for applications such as inverting products for inspection or de-pucking.

Videos

Top Running Loops & Pallet Systems

Accurate Routing

The FlexMove Top Running Loops & Pallet Systems represent a specialized and highly precise segment of the FlexMove product line, designed for applications requiring accurate product handling and routing. These systems utilize a top-running loop design where the chain circulates continuously in a single plane, which is especially beneficial for small manufacturing cells, automation, and assembly processes.

Table Top Conveyors

Low Cost Material Conveying

The FlexMove Tabletop Conveyor is a highly versatile and reliable solution for handling a wide range of products, from small bottles and cans to larger cartons and cases. Characterized by its flat, smooth chain surface, this conveyor provides a stable and consistent platform for product transport. It is exceptionally well-suited for high-speed production environments, offering durability and a low-friction surface that ensures products move seamlessly with minimal risk of tipping or damage.

Weighted Take Up Module

Smooth Long Conveying

The FlexMove Weighted Take-Up Module is a critical component for maintaining peak performance and safety in longer FlexMove conveyor systems. It’s a simple yet highly effective device that automatically compensates for chain stretch using a weighted roller.

By providing consistent and optimal chain tension, the module prevents the chain from sagging or drooping, which eliminates the slight, jerky motion (micro-surging) that can occur on long conveyor runs. This results in smoother product handling, crucial for maintaining product integrity. The module also enhances safety by removing potential pinch points caused by loose chain. Recommended for conveyors over 40 feet in length, it’s an essential add-on for reliable, high-performance operation.

Twist Conveyors

Product Reorienting

The FlexMove Twist Conveyor is an innovative and highly efficient solution for reorienting products within a production line. Unlike other systems that require complex machinery or robotics for product rotation, the Twist conveyor uses a simple yet clever design of two independent, side-by-side conveyor chains.

As the product travels along the two chains, one is slightly elevated and angled, causing the item to gently and positively rotate. This design allows for a smooth, in-line 90-degree twist without the need for product gapping or complex guiding, significantly simplifying the manufacturing process. It is ideal for applications where access to multiple sides of a package is needed, such as for labeling, date-coding, or inspection. The Twist conveyor’s ability to handle multiple product sizes without changeover makes it a highly flexible and time-saving solution for complex packaging and assembly lines.

Top Running Loop Drive Design

Added Strength Driver

The FlexMove Top Running Loop Drive is a specialized and patented drive unit designed for applications where the conveyor chain forms a single, continuous loop without a return chain underneath. This design, often used in spiral, alpine, and pallet systems, is crucial for maximizing floor space and creating continuous product flow.

Unlike traditional drives that pull the chain from one end and return it underneath, the Top Running Loop Drive engages and powers the chain along its top, or product-carrying, surface. This results in a cleaner and more compact system, as there is no need for a return path. It is particularly well-suited for applications that require controlled movement, such as automated assembly, product indexing, and accumulation, as well as for multi-level systems where the conveyor needs to move products vertically with a minimal footprint. Its patented design provides superior strength, flexibility, and load-bearing capacity for demanding, continuous-loop applications.