The Glide-Line 360: Fully Configurable, All-Access Pallet Conveyor System

The Completely Customizable Conveyor Solution

The Glide-Line 360 is a custom conveyor system that can be configured in literally hundreds of thousands of ways to meet your needs. It can shuttle, divert, merge, sort, stack, lift, lower, transfer, and turn – or any combination thereof – in one system. The best part? It doesn’t cost additional time or money, because all the configurations come as standard conveyor set-ups.

When you’re comparing the extreme configurability of the Glide-Line 360 to traditional conveyor solutions, it’s not exactly an apples-to-apples comparison. That’s because the Glide-Line 360 is an outside-the-box solution to conveying; it doesn’t follow traditional conveyor rules, and that’s what makes it so flexible for our integrator clients to use in their conveyor system solutions.

The Glide-Line 360 is a custom solution, standardized.

Videos

Features

- Gentle, more reliable and energy efficient conveyor solution.

- 24VDC brushless motors are maintenance-free and virtually noise-free.

- Can be certified for use in clean room environments.

- Built in driver cards with zero pressure logic and I/O points.

- Can handle loads up to 200 lbs per zone.

- Bearings in motors have 300,000 hour lifespan.

- All maintenance operations including belt changes can be performed from the top, eliminating the need to disassemble or remove ancillary equipment.

- Highly configurable.

- T5 timing style conveyor belts for positive drive and precision positioning ability.

- Extruded aluminum construction with standard 10mm T-slots.

Scroll down to view many of our endless options!

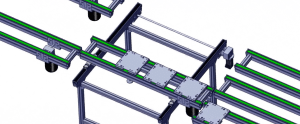

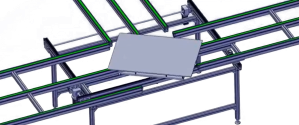

Pallet Shuttle

One of Glide-Line’s 360 Flexible Conveyor Solutions

The pallet shuttle allows traffic to be merged or sorted. For example, pallets can be merged from three lanes into one lane, or they can be sorted from one lane into three.

Videos

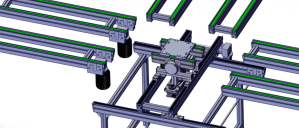

Pallet Transfer Shuttle & Merge

One of Glide-Line’s 360 Flexible Conveyor Solutions

The rotate & shuttle allows a pallet to be moved from location to another while at the same time manipulating the orientation of the pallet.

Videos

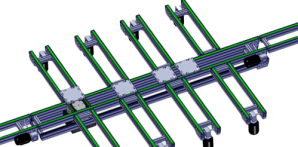

Pallet Lift and Transfer Shuttle

One of Glide-Line’s 360 Flexible Conveyor Solutions

This solution has a small lift and transfer conveyor running the length of a trunk line. It can accept product at one or more location and drop off at multiple locations along the same trunk.

Videos

Pallet Buffer

One of Glide-Line’s 360 Flexible Conveyor Solutions

A VTU base unit can be used to create multiple levels of conveyors or shelves for uses as a buffer system.

Videos

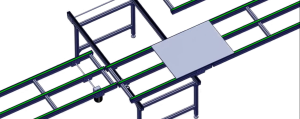

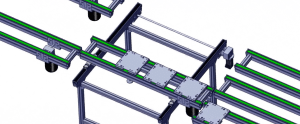

Panel Shuttle

One of Glide-Line’s 360 Flexible Conveyor Solutions

This solution makes a section of conveyor mobile in a single axis so that panels can be received one or more conveyor lanes and distribute to other lanes.

Videos

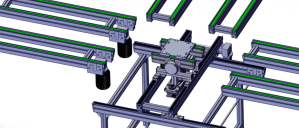

Panel Lift Rotate Shuttle

One of Glide-Line’s 360 Flexible Conveyor Solutions

The rotate & shuttle allows a panel to be moved from location to another while at the same time manipulating the orientation of the panel.

Videos

Centerline Adjust Conveyor

One of Glide-Line’s 360 Flexible Conveyor Solutions

By utilizing 360 on independent conveyor strands, we can automatically adjust the width between strands as the application demands. This can be done on one or both strands.

Videos

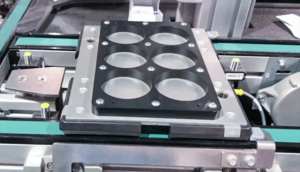

Roller Lift Transfer Unit

One of Glide-Line’s 360 Flexible Conveyor Solutions

Roller Lift Transfer Units utilize a series of rollers to lift and engage the payload perpendicular to the direction of flow. The lifting action raises the payload from the in feed conveyor so it can be moved onto the adjacent transport conveyor. The unit is bi-directional and can be set up to manage two, three, and four-way traffic control conditions.

The Glide-Line 360: Fully Configurable, All-Access Pallet Conveyor System

The Completely Customizable Conveyor Solution

The Glide-Line 360 is a custom conveyor system that can be configured in literally hundreds of thousands of ways to meet your needs. It can shuttle, divert, merge, sort, stack, lift, lower, transfer, and turn – or any combination thereof – in one system. The best part? It doesn’t cost additional time or money, because all the configurations come as standard conveyor set-ups.

When you’re comparing the extreme configurability of the Glide-Line 360 to traditional conveyor solutions, it’s not exactly an apples-to-apples comparison. That’s because the Glide-Line 360 is an outside-the-box solution to conveying; it doesn’t follow traditional conveyor rules, and that’s what makes it so flexible for our integrator clients to use in their conveyor system solutions.

The Glide-Line 360 is a custom solution, standardized.

Videos

Features

- Gentle, more reliable and energy efficient conveyor solution.

- 24VDC brushless motors are maintenance-free and virtually noise-free.

- Can be certified for use in clean room environments.

- Built in driver cards with zero pressure logic and I/O points.

- Can handle loads up to 200 lbs per zone.

- Bearings in motors have 300,000 hour lifespan.

- All maintenance operations including belt changes can be performed from the top, eliminating the need to disassemble or remove ancillary equipment.

- Highly configurable.

- T5 timing style conveyor belts for positive drive and precision positioning ability.

- Extruded aluminum construction with standard 10mm T-slots.

Scroll down to view many of our endless options!

Pallet Shuttle

One of Glide-Line’s 360 Flexible Conveyor Solutions

The pallet shuttle allows traffic to be merged or sorted. For example, pallets can be merged from three lanes into one lane, or they can be sorted from one lane into three.

Videos

Pallet Transfer Shuttle & Merge

One of Glide-Line’s 360 Flexible Conveyor Solutions

The rotate & shuttle allows a pallet to be moved from location to another while at the same time manipulating the orientation of the pallet.