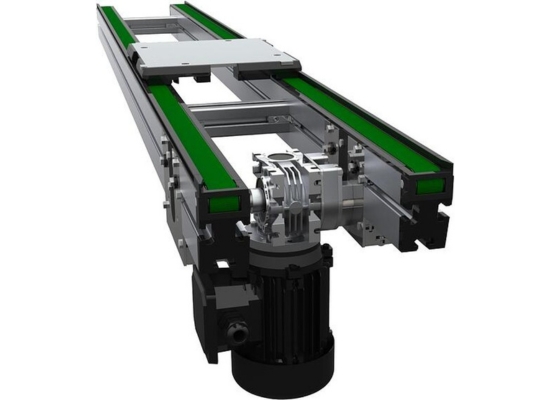

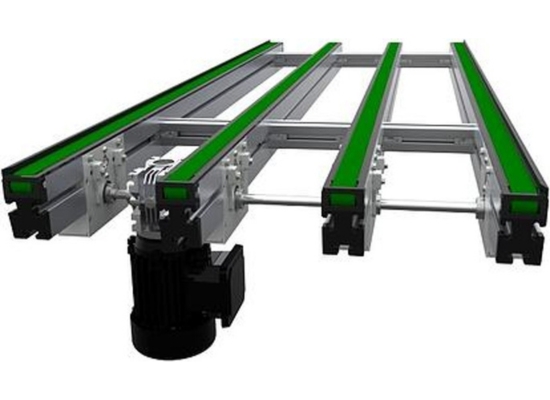

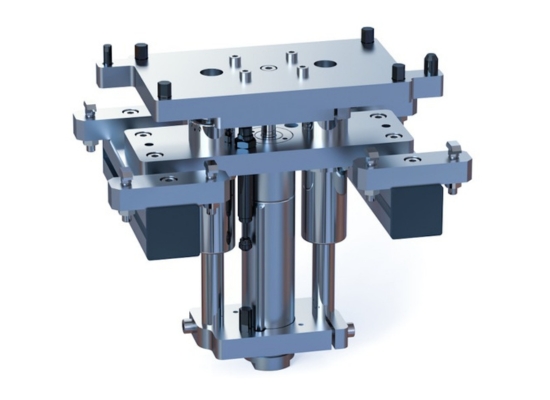

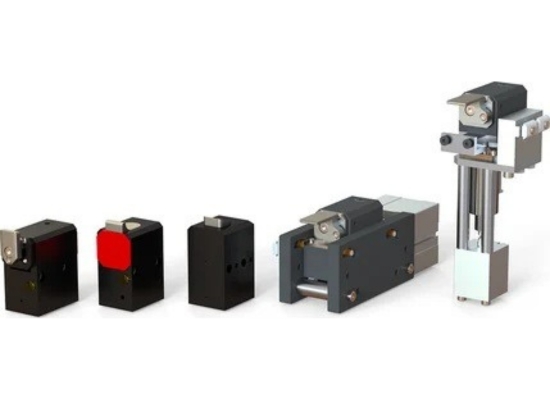

Timing Belt Single-Strand Conveyors for Precision Product Handling Highly Configurable A configurable conveyor designed for precision indexing, durability and clean room environments, Glide-Line Single Strand solutions are a great fit for the Feeder Industry. This is a best in class solution at a competitive price made possible by using 21st century advanced manufacturing and engineering […]

Timing Belt – Single-Strand Solutions