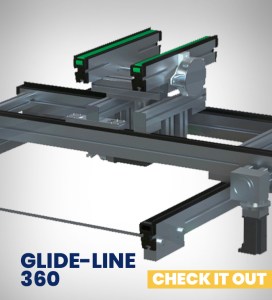

Glide-Line 360

The Completely Customizable Conveyor Solution

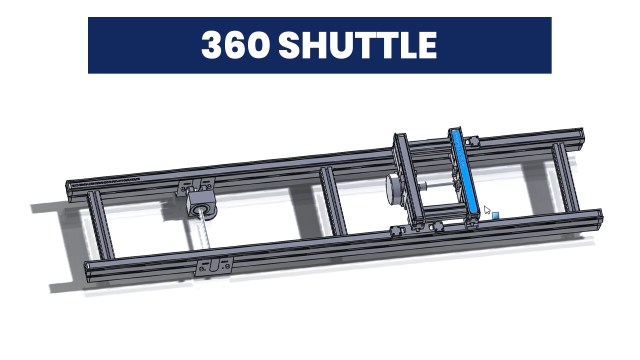

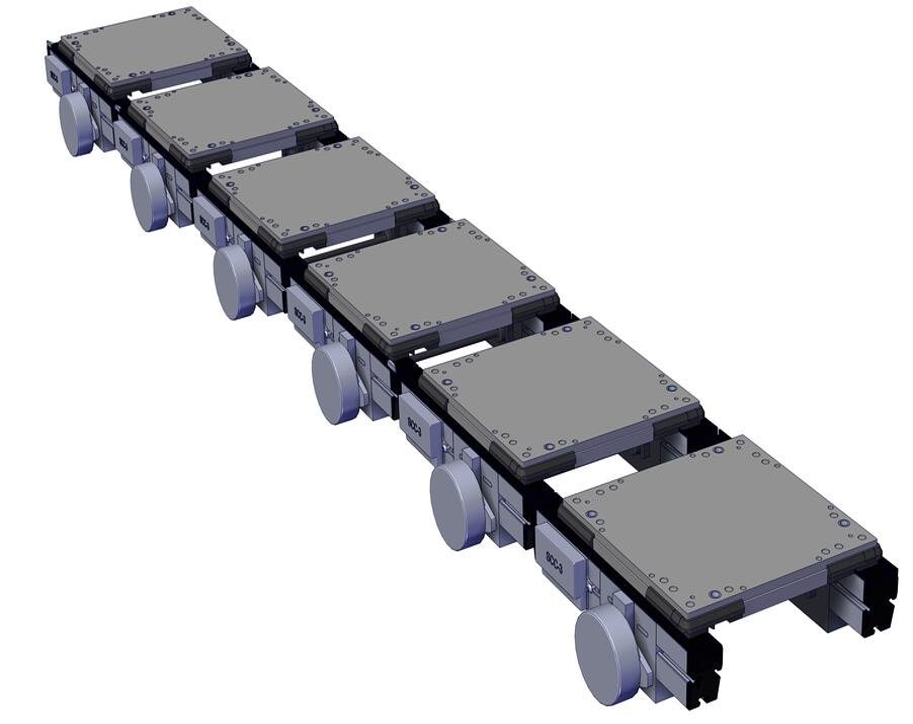

The Glide-Line 360 is a custom conveyor system that can be configured in literally hundreds of thousands of ways to meet your needs. It can shuttle, divert, merge, sort, stack, lift, lower, transfer, and turn – or any combination thereof – in one system. The best part? It doesn’t cost additional time or money, because all the configurations come as standard conveyor set-ups.

When you’re comparing the extreme configurability of the Glide-Line 360 to traditional conveyor solutions, it’s not exactly an apples-to-apples comparison. That’s because the Glide-Line 360 is an outside-the-box solution to conveying; it doesn’t follow traditional conveyor rules, and that’s what makes it so flexible for our integrator clients to use in their conveyor system solutions.

The Glide-Line 360 is a custom solution, standardized.

Videos

Features

- Gentle, more reliable and energy efficient conveyor solution.

- 24VDC brushless motors are maintenance-free and virtually noise-free.

- Can be certified for use in clean room environments.

- Built in driver card with zero pressure logic and I/O points.

- Can handle loads up to 200lbs per zone.

- Bearings in motors have 300,000 hour lifespan.

- All maintenance operations including belt changes can be performed from the top, eliminating the need to disassemble or remove ancillary equipment.

- Highly Configurable.

- T5 timing style conveyor belts for positive drive and precision positioning ability.

- Extruded aluminum construction with standard 10mm T-slots.

Glide-Line 360

The Completely Customizable Conveyor Solution

The Glide-Line 360 is a custom conveyor system that can be configured in literally hundreds of thousands of ways to meet your needs. It can shuttle, divert, merge, sort, stack, lift, lower, transfer, and turn – or any combination thereof – in one system. The best part? It doesn’t cost additional time or money, because all the configurations come as standard conveyor set-ups.

When you’re comparing the extreme configurability of the Glide-Line 360 to traditional conveyor solutions, it’s not exactly an apples-to-apples comparison. That’s because the Glide-Line 360 is an outside-the-box solution to conveying; it doesn’t follow traditional conveyor rules, and that’s what makes it so flexible for our integrator clients to use in their conveyor system solutions.

The Glide-Line 360 is a custom solution, standardized.

Features

- Gentle, more reliable and energy efficient conveyor solution.

- 24VDC brushless motors are maintenance-free and virtually noise-free.

- Can be certified for use in clean room environments.

- Built in driver card with zero pressure logic and I/O points.

- Can handle loads up to 200lbs per zone.

- Bearings in motors have 300,000 hour lifespan.

- All maintenance operations including belt changes can be performed from the top, eliminating the need to disassemble or remove ancillary equipment.

- Highly Configurable.

- T5 timing style conveyor belts for positive drive and precision positioning ability.

- Extruded aluminum construction with standard 10mm T-slots.