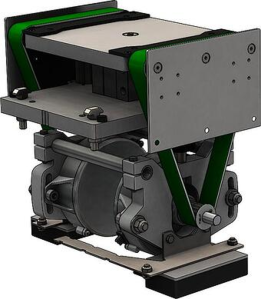

Lift Transfer Unit

Accuracy with a Small Footprint

Lift Transfer Units move work piece pallets from one transport conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two, three, and four-way traffic control conditions.

Videos

Specifications

- Speed Range – 3.5 to 70 m/min

- Bi-directional operation

- Payload Capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm to 1040mm in 1mm increments

- Pallet width range – 160mm to 1040mm in1mm increments

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- 50mm bore lift cylinder

- 10mm lift stroke – 2mm below conveying surface to 8mm above conveying surface

- G1/8 ports

Features

- T5 timing style conveyor belts for positive drive

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Various bolt-on dampened stops available

- Guard package

- 24VDC enclosed drive system

- Additional DC drive options including control cards

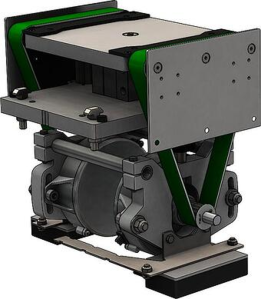

Lift Transfer Unit

Accuracy with a Small Footprint

Lift Transfer Units move work piece pallets from one transport conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two, three, and four-way traffic control conditions.

Specifications

- Speed Range – 3.5 to 70 m/min

- Bi-directional operation

- Payload Capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm to 1040mm in 1mm increments

- Pallet width range – 160mm to 1040mm in1mm increments

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- 50mm bore lift cylinder

- 10mm lift stroke – 2mm below conveying surface to 8mm above conveying surface

- G1/8 ports

Features

- T5 timing style conveyor belts for positive drive

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Various bolt-on dampened stops available

- Guard package

- 24VDC enclosed drive system

- Additional DC drive options including control cards