Zone-Controlled Conveying: Why Intelligent Conveyors Are the Future

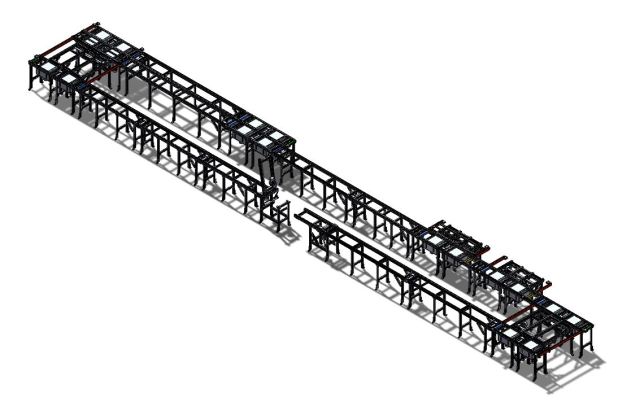

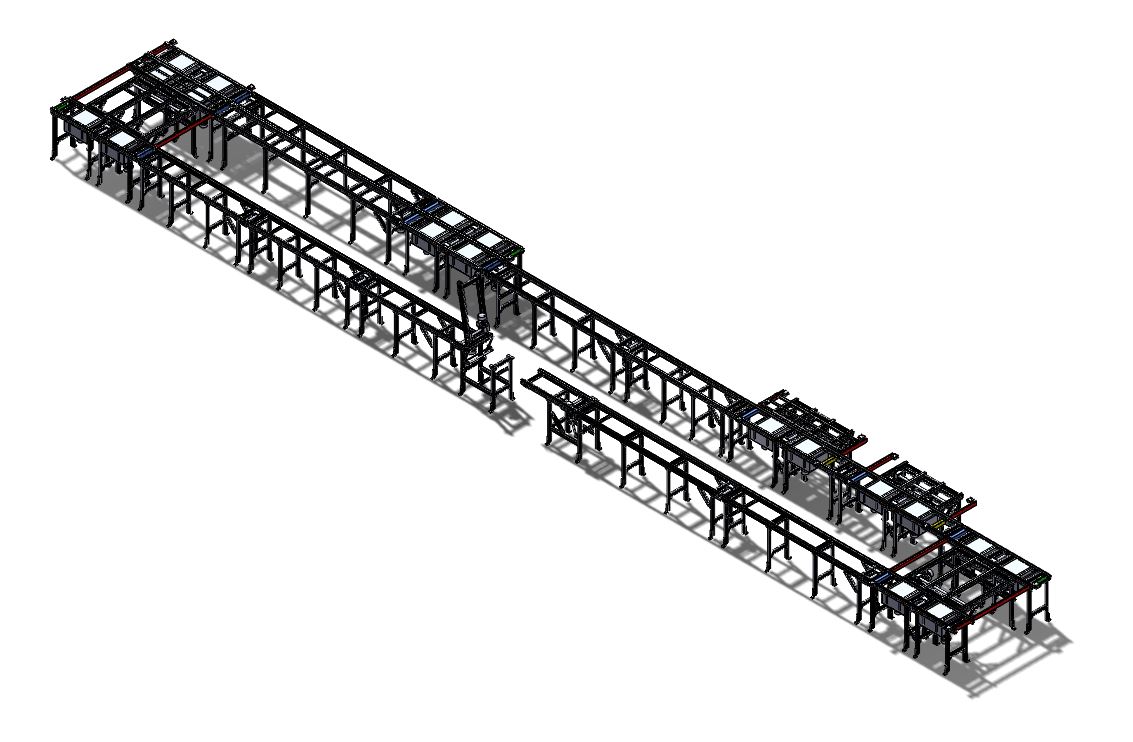

Conveyor systems are no longer just simple belts moving products from point A to B. Intelligent, zone-controlled systems use sensors and logic to create smart, responsive flow control.

With zone-controlled conveyors, each product moves independently through predefined zones. Zero-pressure accumulation means no product contact, less damage, and reduced mechanical wear. In Glide-Line systems, zone control also supports variable speed, indexing, and integration with robotics or vision systems.

The benefits? Faster throughput, less downtime, and safer operation. Smart conveying reduces bottlenecks and improves control—and it’s quickly becoming the new standard in high-performance automation.

Conveyors have come a long way from simple belts that move parts from point A to B. Today, more manufacturers are turning to zone-controlled conveyors for smarter, more responsive material handling. But what exactly are they, and where do they deliver the most value?

What Is a Zone-Controlled Conveyor?

A zone-controlled conveyor is a conveyor system that is divided into multiple independently controlled zones. Each zone typically has its own motor and sensor, allowing it to start or stop based on product presence. Products move independently from one zone to another without contacting each other.

This design enables zero-pressure accumulation (ZPA)—a method of accumulating products without any physical contact. As one zone becomes occupied, upstream zones stop moving, preventing product collisions or backup jams.

Key Features and Capabilities

Zone-controlled conveyors aren’t just about starting and stopping. They offer a wide range of capabilities that are reshaping automated production lines:

- Independent control of product movement for precision spacing

- Zero-pressure accumulation to prevent product damage

- Programmable logic control (PLC) integration for sequencing and timing

- Gap creation for inspection or robotic pick-and-place

- Variable speed control per zone

- Built-in diagnostics and sensor feedback

- Smooth merging and diverging of product flows

These capabilities allow zone-controlled conveyors to support high-speed operations with more control, higher safety, and fewer mechanical stress points.

Why Zone Control Matters in Automation

Unlike conventional conveyors that rely on manual control or physical accumulation, zone-controlled systems are responsive. That means they can:

- Reduce downtime from jams and collisions

- Minimize wear on belts, motors, and drives

- Protect sensitive products from impact

- Enable smarter integration with robotics, inspection, and packaging systems

- Improve line efficiency by synchronizing with varying cycle times

Zone control enables better flow management and real-time decision-making on the conveyor—without the need for additional hardware or labor.

Industry Application 1: Electronics Assembly

In electronics manufacturing, where fragile components and sensitive PCBs are common, zone-controlled conveyors provide non-contact transport and precise positioning.

Boards can be spaced for automated soldering or visual inspection. If one board pauses for a test, others upstream stop safely without stacking or pressure. This protects high-value goods and maintains consistent flow even when subprocesses vary in cycle time.

Industry Application 2: Consumer Goods Packaging

High-speed packaging lines often handle various SKUs with different shapes and packaging needs. A zone-controlled conveyor can adapt instantly to changes in product size and packing sequence.

For example, in a line packaging cosmetic bottles, zone logic can create gaps between products for labeling, inspection, or robotic packing. If a downstream station halts, upstream zones accumulate without damaging or scuffing the bottles.

Industry Application 3: Medical Device Manufacturing

In cleanroom environments, medical devices require careful handling with no cross-contamination. Zone-controlled conveyors reduce human intervention while maintaining precise transport.

Devices can move individually through inspection, UV sanitation, or packaging steps, all without touching or jostling. Integrated sensors can monitor movement, track production, and trigger alerts if conditions vary—supporting both efficiency and traceability.

Zone-controlled conveyors are becoming the backbone of smart manufacturing. With their ability to manage product flow independently, integrate with advanced automation systems, and reduce operational risk, they offer a strategic advantage for companies pushing toward leaner, cleaner, and more connected production.

Glide-Line’s zone-controlled systems are fully modular, PLC-ready, and designed for fast integration. Whether you’re automating electronics, packaging, or medical devices, this technology opens the door to smoother, safer, and more scalable production lines. Contact us today for your industrial conveying needs.