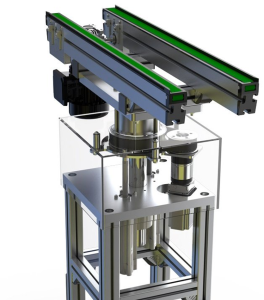

Drop & Rotate Transfer Units: Compact Pallet Routing and Orientation

Compact 360 Degree Rotation

DART Drop and Rotate Transfer Unit is a revolutionary innovation for pallet and work piece handling designed to simplify layouts and reduce cost. This specialized hub has been specifically design to maximize layouts and save complexity and cost. The DART system is a powered conveyor that can rotate from 1 degree to 360 degrees to accomplish almost any angle transfer in a system, including conventional right angle transfers. The pallet can either rotate with it (changing orientation) or stay static (maintaining orientation). With this new design in your overall layout design toolbox, Glide-Line’s DART will allow for endless opportunities and maximize assembly workspace.

All stops can be configured to be pneumatically single or double acting, to stop work-piece pallets so an operation can be performed. Dampened Stops offer a pneumatic cushioning force to the work piece that slows the impact of the pallet against the stop. The cushioning force can be adjusted to suit specific application needs. Larger stops and higher cushioning forces are available upon request.

Anti-Rebound pallet stops can be utilized as a unidirectional stop gate to prevent pallets from moving if the conveyor belt reverses direction in the application.

Drop-Away pallet stops are designed to work at an LTU (Lift and Transfer Unit) intersection where pallets are required to traverse in multiple directions.

Videos

Specifications

- Used as a centralized hub, DART can help solve complex pallet and work piece distribution challenges

- Is capable of operating with more than two stands of conveyor, ideal for handling heavier pallets and large panels

- Develop higher level automated systems at a lower relative cost

- DART utilizes many of our standard conveyor and device parts

Features

- Servo driven rotation for smooth rapid and precise positioning

- The device does not violate the space between the conveyor strands so all of the standard conveyor mounted stops and accessories can be used

- Static center plate available to maintain work piece orientation when making right angle transfers

- Smooth pneumatic vertical motion with integrated adjustable air cushions

Options

- By managing complex traffic control conditions, DART makes it possible to minimize the size of your overall system

- Simplifies pallet handling by utilizing standard conveyor mounted pallet stops and accessories

- More cost effective than using typical lift transfers units

- Use the DART to rotate and transfer in a single station

- Much less complicated than alternative systems

Downloads

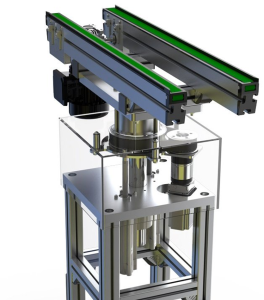

Drop & Rotate Transfer Units: Compact Pallet Routing and Orientation

Compact 360 Degree Rotation

DART Drop and Rotate Transfer Unit is a revolutionary innovation for pallet and work piece handling designed to simplify layouts and reduce cost. This specialized hub has been specifically design to maximize layouts and save complexity and cost. The DART system is a powered conveyor that can rotate from 1 degree to 360 degrees to accomplish almost any angle transfer in a system, including conventional right angle transfers. The pallet can either rotate with it (changing orientation) or stay static (maintaining orientation). With this new design in your overall layout design toolbox, Glide-Line’s DART will allow for endless opportunities and maximize assembly workspace.

All stops can be configured to be pneumatically single or double acting, to stop work-piece pallets so an operation can be performed. Dampened Stops offer a pneumatic cushioning force to the work piece that slows the impact of the pallet against the stop. The cushioning force can be adjusted to suit specific application needs. Larger stops and higher cushioning forces are available upon request.

Anti-Rebound pallet stops can be utilized as a unidirectional stop gate to prevent pallets from moving if the conveyor belt reverses direction in the application.

Drop-Away pallet stops are designed to work at an LTU (Lift and Transfer Unit) intersection where pallets are required to traverse in multiple directions.

Videos

Specifications

- Used as a centralized hub, DART can help solve complex pallet and work piece distribution challenges

- Is capable of operating with more than two stands of conveyor, ideal for handling heavier pallets and large panels

- Develop higher level automated systems at a lower relative cost

- DART utilizes many of our standard conveyor and device parts

Features

- Servo driven rotation for smooth rapid and precise positioning

- The device does not violate the space between the conveyor strands so all of the standard conveyor mounted stops and accessories can be used

- Static center plate available to maintain work piece orientation when making right angle transfers

- Smooth pneumatic vertical motion with integrated adjustable air cushions

Options

- By managing complex traffic control conditions, DART makes it possible to minimize the size of your overall system

- Simplifies pallet handling by utilizing standard conveyor mounted pallet stops and accessories

- More cost effective than using typical lift transfers units

- Use the DART to rotate and transfer in a single station

- Much less complicated than alternative systems