Timing Belt Lift & Locate Units for Precision Workstation Positioning

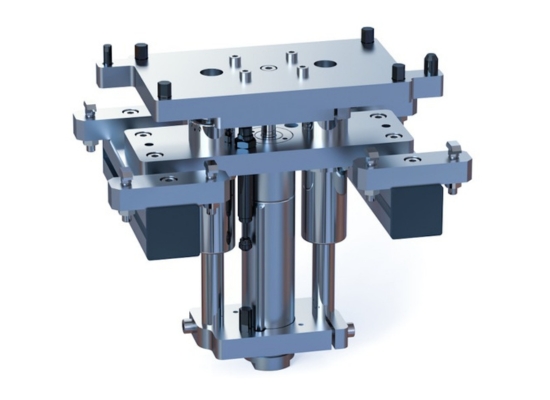

Accurate Lifting & Positioning

Lift and Locate devices are used to lift a pallet off the belt to position accurately for external operations. Positional accuracy is typically +/- .05mm but can be tighter or looser based upon the application requirements. The Standard and Low Profile lift and locates are most common with the main difference being vertical stroke (standard lift and locate offers 3-200mm z-axis adjustment). The Heavy Duty lift and locate is capable of supporting massive downward force, and the Lift and Position Kit is typically used on larger pallets.

Specifications

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion

- Lift range 1.5mm to 200mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm – 1040mm in 1mm increments

- Pallet width range – 160mm – 1040mm in 1mm increments

- ¼ NPT ports

- Standard pin accuracy of +/- 0.05mm

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- High tolerance locating pins available

Low-Profile Lift &

Locate Unit

Accuracy with a Small Footprint

Low-Profile Lift and Locate Unit (LLLU) offers vertical lift positioning in a small footprint, and it is suitable for applications that require repeatable, positional accuracy within ±.05mm. Additional fit options are available on request for lower tolerance applications. The low-profile design allows the LLLU to be used in situations that have limited clearance below the conveyor.

Videos

Specifications

- Lifts and locates pallet 1.5mm above belt

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm – 400mm in 1mm increments

- Pallet width range – 160mm – 400mm in 1mm increments

Features

- Pneumatic lift actuation

- Low profile allows for installation in areas with limited space

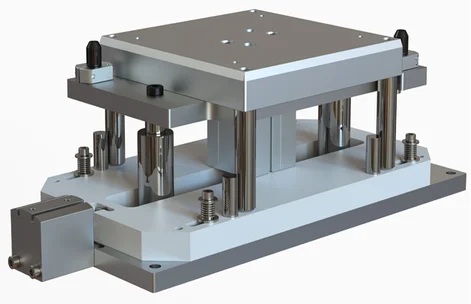

Heavy Duty Lift &

Locate Unit

Heavy Duty Lifting

The Heavy Duty Lift and Locate Unit delivers repeatable, positional accuracy within ±.05mm. The vertical lift position is fixed at 1.5mm above the belt, and the unit is designed to handle heavy loads for press operations such as swaging and ultrasonic welding. This unit utilizes a pneumatic shuttle that slips between the baseplate and the lift anvil once the pallet is raised into position. Heavy Duty Units must be station-mounted on suitable structures to absorb the required loads; accuracy and repeatability are relative to the mounting structure.

Videos

Specifications

- Station mounted only

- Lifts and locates pallet 1.5mm above belt

- Lateral and vertical location repeatability within .05mm

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- Load absorption capacity when in locked position starts at 20,000 Lbs

- Pallet length range – 160mm – 400mm in 1mm increments

- Pallet width range – 160mm – 400mm in 1mm increments

- CUSTOM options available for sizes greater than 400mm

- Non-evenly distributed center loads may require additional engineering and material

Features

- Pneumatic lift actuation

- Pneumatic shuttle lock for heavy load absorption

- Force absorption zone covers the entire anvil surface

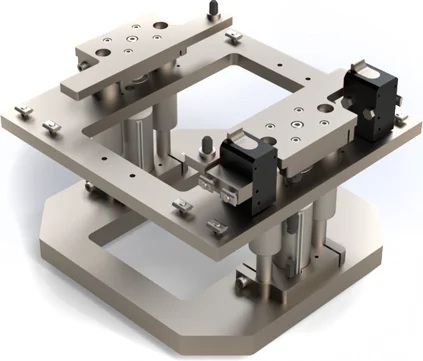

Open Center Lift

& Locate Unit

Fully Configurable Lift Positioning

The Open Center Lift and Locate Unit offers fully configurable vertical lift positioning, and it is suitable for applications that require repeatable, positional accuracy within ±.05mm. The unit can be station-mounted or mounted directly to the transport conveyor; accuracy and repeatability are relative to the mounting structure.

Specifications

- Flexibility in the design and can also accomplish the same result with the lift and position kit (minus the cross bars).

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion.

- Standard stroke lift range 1mm to 200mm

- Short stroke lift range 1mm to 75mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm.

- 40mm bore lift cylinder.

- Lift capacity – 150 Lbs. @ 80 psi.

- Pallet length range – 160mm – 1040mm in 1mm increments.

- Pallet width range – 160mm – 1040mm in 1mm increments.

- G1/8 ports

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- Mid and High tolerance locating pins available

Lift Position Kit

For Larger Pallets

Lift and Position Kit is a highly configurable device, specifically designed for larger pallets that allows one to locate only, lift only, or both lift and locate. This device mounts directly to the bottom of the conveyor T-slot. When locating, the position cylinders are capable of repeatable, positional accuracy within ±.05mm.

Specifications

- Conveyor mounted

- Lifts and locates pallet 1.5mm above belt

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- G1/8 Ports

- Pallet length minimum – 240mm*

- Pallet width minimum – 295mm*

Features

- Pneumatic lift actuation

- Lift and locates large pallet sizes

- Can be configured as lift only, lift and locate, or locate only

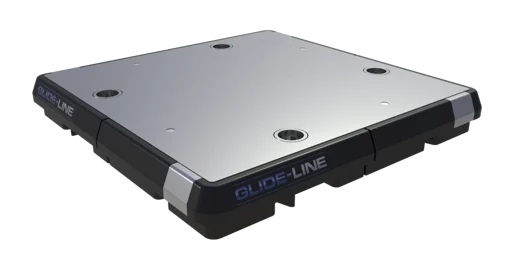

Work Piece Pallet

Secure Precise Pallet Transport

Glide-Line pallets work as a carrier for work pieces as they move around a conveyor system. Most pallets are tooled with custom fixturing components to secure work pieces as they are handled, and each pallet contains a set of precision bushings for exact pallet location at each workstation by means of our Lift and Locate Units.

Specifications

- Length range – 160mm to 1040mm in 1mm increments

- Width range – 160mm to 1040mm in 1mm increments

Features

- Length and width range from 160mm to 1040mm

- Various tool plate materials available

- Precision custom machining available

- Can be supplied assembled, unassembled, or kits (no tool plate)

Options

- Baseplate materials:

- Standard Aluminum

- Special Request: Stainless Steel, Carbon Steel, Plastic.

- Custom baseplate machining available

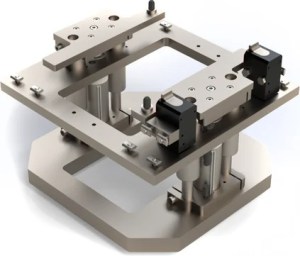

Standard Lift & Locate Units

Accurate Lifting & Positioning

Lift and Locate devices are used to lift a pallet off the belt to position accurately for external operations. Positional accuracy is typically +/- .05mm but can be tighter or looser based upon the application requirements. The Standard and Low Profile lift and locates are most common with the main difference being vertical stroke (standard lift and locate offers 3-200mm z-axis adjustment). The Heavy Duty lift and locate is capable of supporting massive downward force, and the Lift and Position Kit is typically used on larger pallets.

Specifications

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion

- Lift range 1.5mm to 200mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm – 1040mm in 1mm increments

- Pallet width range – 160mm – 1040mm in 1mm increments

- ¼ NPT ports

- Standard pin accuracy of +/- 0.05mm

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- High tolerance locating pins available

Low-Profile Lift & Locate Unit

Accuracy with a Small Footprint

Low-Profile Lift and Locate Unit (LLLU) offers vertical lift positioning in a small footprint, and it is suitable for applications that require repeatable, positional accuracy within ±.05mm. Additional fit options are available on request for lower tolerance applications. The low-profile design allows the LLLU to be used in situations that have limited clearance below the conveyor.

Specifications

- Lifts and locates pallet 1.5mm above belt

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm – 400mm in 1mm increments

- Pallet width range – 160mm – 400mm in 1mm increments

Features

- Pneumatic lift actuation

- Low profile allows for installation in areas with limited space

Heavy Duty Lift & Locate Unit

Heavy Duty Lifting

The Heavy Duty Lift and Locate Unit delivers repeatable, positional accuracy within ±.05mm. The vertical lift position is fixed at 1.5mm above the belt, and the unit is designed to handle heavy loads for press operations such as swaging and ultrasonic welding. This unit utilizes a pneumatic shuttle that slips between the baseplate and the lift anvil once the pallet is raised into position. Heavy Duty Units must be station-mounted on suitable structures to absorb the required loads; accuracy and repeatability are relative to the mounting structure.

Specifications

- Station mounted only

- Lifts and locates pallet 1.5mm above belt

- Lateral and vertical location repeatability within .05mm

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- Load absorption capacity when in locked position starts at 20,000 Lbs

- Pallet length range – 160mm – 400mm in 1mm increments

- Pallet width range – 160mm – 400mm in 1mm increments

- CUSTOM options available for sizes greater than 400mm

- Non-evenly distributed center loads may require additional engineering and material

Features

- Pneumatic lift actuation

- Pneumatic shuttle lock for heavy load absorption

- Force absorption zone covers the entire anvil surface

Open Center Lift & Locate Unit

Fully Configurable Lift Positioning

The Open Center Lift and Locate Unit offers fully configurable vertical lift positioning, and it is suitable for applications that require repeatable, positional accuracy within ±.05mm. The unit can be station-mounted or mounted directly to the transport conveyor; accuracy and repeatability are relative to the mounting structure.

Specifications

- Flexibility in the design and can also accomplish the same result with the lift and position kit (minus the cross bars).

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion.

- Standard stroke lift range 1mm to 200mm

- Short stroke lift range 1mm to 75mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm.

- 40mm bore lift cylinder.

- Lift capacity – 150 Lbs. @ 80 psi.

- Pallet length range – 160mm – 1040mm in 1mm increments.

- Pallet width range – 160mm – 1040mm in 1mm increments.

- G1/8 ports

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- Mid and High tolerance locating pins available

Lift Position Kit

For Larger Pallets

Lift and Position Kit is a highly configurable device, specifically designed for larger pallets that allows one to locate only, lift only, or both lift and locate. This device mounts directly to the bottom of the conveyor T-slot. When locating, the position cylinders are capable of repeatable, positional accuracy within ±.05mm.

Specifications

- Conveyor mounted

- Lifts and locates pallet 1.5mm above belt

- 40mm bore lift cylinder

- Lift capacity – 150 Lbs. @ 80 psi

- G1/8 Ports

- Pallet length minimum – 240mm*

- Pallet width minimum – 295mm*

Features

- Pneumatic lift actuation

- Lift and locates large pallet sizes

- Can be configured as lift only, lift and locate, or locate only

Work Piece Pallet

Secure Precise Pallet Transport

Glide-Line pallets work as a carrier for work pieces as they move around a conveyor system. Most pallets are tooled with custom fixturing components to secure work pieces as they are handled, and each pallet contains a set of precision bushings for exact pallet location at each workstation by means of our Lift and Locate Units.

Specifications

- Length range – 160mm to 1040mm in 1mm increments

- Width range – 160mm to 1040mm in 1mm increments

Features

- Length and width range from 160mm to 1040mm

- Various tool plate materials available

- Precision custom machining available

- Can be supplied assembled, unassembled, or kits (no tool plate)

Options

- Baseplate materials:

- Standard Aluminum

- Special Request: Stainless Steel, Carbon Steel, Plastic.

- Custom baseplate machining available