Vertical Transport Units (VTU): Efficiently Move Pallets Between Floors

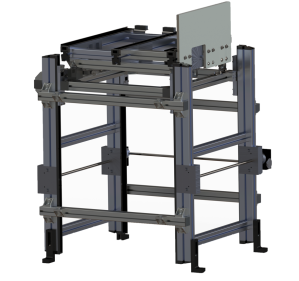

Dual Lift Vertical Transport Unit

A dual lift VTU configuration has two (2) independent actuators that enable two Z-axis movements at a time and two independent decks. This can be used many ways.

Examples:

- Decouple an upper and lower transfer

- Sorting product to / from multiple in-feeds and discharges

- Perform an operation on one product while keeping the VTU in operation for others

Videos

Options

- Can be driven with any electric motor – AC (Motor Brake Required), stepper / servo, etc.

- Complete flexibility of geometry (size, lift stroke, etc.)

Dual Deck VTU

Accuracy with a Small Footprint

Allows for vertical transfer of product on two transport conveyors simultaneously.

- A standard Vertical Transfer Unit with two transport deck conveyors

- Provides the ability to transport twice the amount of product vertically

- This is especially useful for processes requiring fast-paced throughput

- The number of transport decks can be increased to shift as many products vertically as desired

Options

- Can be driven with an electric motor – stepper / servo

- Quantity of transport deck conveyors can be added as needed

- Complete flexibility of geometry (size, lift stroke, etc.)

Low-Cost Mini VTU

Affordable Vertical Transferring

The Low Cost Mini VTU was built for those who are looking for creative space use and cost savings.

Due to the configurable nature of our systems, curves can be configured as options of 30, 45, 60, 90, and 180 degrees, other custom options are available upon request.

Specifications

- Lift range up to 250mm**

- Lift cylinder bore of 40mm

- **Lift capacity (including deck CV and pallet) of 150 Lbs @ 80 psi

- **Standard pallet length and width range of 160mm – 400mm

- **custom options available outside these ranges/values specified above upon verification from engineering*¼ NPT ports

Features

- A simple short Vertical Transport Unit (VTU) for limited vertical stroke applications

- Pneumatically actuated

- 102mm clearance for pallet and product on bottom level

Options

- Guarding

Tilting Deck VTU

Fully Configurable Lift Positioning

Allows for vertical transfer of product as well as tilting the conveyor deck up to 30° to allow for flexible access to the product being transported.

- A standard Vertical Transfer Unit with the addition of a tilting transport deck conveyor

- Provides the ability to tilt the product towards a robot or operator for improved access to the product

- Tilt feature is controlled by the VTU servo/motor which allows for the transport deck conveyor to tilt up to 30°. Deck is hinged on one side and loose on the other, allowing different Z-axis movements to provide various tilting angles

Videos

Features

- Step-servo control of the z-axis allows maximum tilting flexibility.

- Various sizes, angles and access points are all possible

Multiple Position VTU

Fully Configurable Lift Positioning

Allows for vertical transfer of product from one or more in-feed conveyors to multiple discharge conveyors.

- A standard Vertical Transfer Unit that feeds multiple input and output conveyors

- The total number of infeed and outfeed conveyors can be increased, as needed, to maximize product flow.

- Servo-driven elevator allows for multiple position stopping with precision movement

- The number of transport decks can also be increased to shift as many products vertically as desired.

Videos

Options

- Can be driven with an electric motor – stepper / servo

- Quantity of infeed, outfeed, and transport deck conveyors can be added as needed

- Complete flexibility of geometry (size, lift stroke, etc.)

Pass Through VTU

Fully Configurable Lift Positioning

The vertical transfer unit lifts product off the main line to prevent stoppage of product flow.

- A Dual Deck Vertical Transport Unit that elevates product above main line to allow work to be done from above.

- The bottom transport deck replaces the top when shifted vertically to allow downstream product to bypass and move ahead

- Useful for performing the same process at multiple stations without disturbing product flow.

- Servo-driven elevator allows precision movement and stoppage

Options

- Can be driven with an electric motor – stepper / servo

- Complete flexibility of geometry (size, lift stroke, etc.)

Bypass Lift VTU

Fully Configurable Lift Positioning

Two independently powered lift decks combined into one space to provide product bypass above the main line while simultaneously allowing undisturbed product flow to multiple positions.

- Two standard Vertical Transfer Unit decks contained within a single VTU footprint

- One elevator performs bypass to lift product above the main line

- The second elevator can simultaneously shift to multiple positions to allow product flow to continue downstream or to a return conveyor

- Servo-driven elevator allows for multiple position stopping with precision movement

- Especially useful in tight workspaces to allow multiple tasks to be performed within the same workspace

Options

- Can be driven with an electric motor – stepper or servo based upon the application needs

- Complete flexibility of geometry (size, lift stroke, etc.)

Rack Feeder

Fully Configurable Lift Positioning

Allows for vertical transfer of product to be stored on multiple independently driven stacked conveyors.

- A Vertical Transport Unit feeds product to a rack of independently driven conveyors.

- Maximum amount of product can be stored in a small footprint

- Independently-driven stacked conveyors allow for quick storage and retrieval processes to decrease cycle time

- Servo-driven elevator allows precision movement and stoppage to multiple positions

Videos

Options

- Can be driven with an electric motor – stepper / servo,

- Quantity of stacked conveyors can be increased as needed

- Complete flexibility of overall geometry

Machine Tending Solution

Fully Configurable Lift Positioning

A vertical sortation and storage device to create a buffer of pallets either upstream or downstream (or both) of a machine. Allows an operator to load up a machine with unfinished goods and automatically load parts, and can even simultaneously unload parts. This machine tending solution can greatly reduce operator involvement and keep your valuable machines running while you attend to other tasks.

Features

- Can be driven with any electric motor – AC, stepper / servo, etc.

- This basic concept can be used as an interim buffer/storage concept

- Is infinitely flexible with levels, sizing, etc.

- Servo based for speed, precise motion control and accuracy

Vertical Transport Units (VTU): Efficiently Move Pallets Between Floors

Dual Lift Vertical Transport Unit

A dual lift VTU configuration has two (2) independent actuators that enable two Z-axis movements at a time and two independent decks. This can be used many ways. Learn more in this blog: 3 Ways to Save Space by Integrating Vertically Stacked Conveyors and VTUs

Examples:

- Perform an operation on one product while keeping the VTU in operation for others

- Decouple an upper and lower transfer

- Sorting product to / from multiple in-feeds and discharges

Specifications

- Speed Range – 3.5 to 70 m/min based on a 1750 motor RPM

- Transport Payload Capacity – 250 Lbs. per strand

- Minimum Strand length – 174mm

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- Extruded aluminum construction with standard 10mm T-slots

Features

- T5 timing style conveyor belts for positive drive and precision positioning ability

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Certified for use in clean room environments

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- All maintenance operations including belt changes can be performed from the top eliminating the need to disassemble or remove ancillary equipment

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Configurable cross-members – Define the number and position of cross-members desired

- Configurable break points – Define break points in the frame for convenient assembly and breakdown

- Belt covering – All belt cores are polyurethane with steel tension members

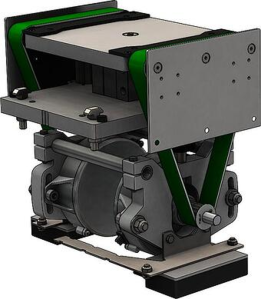

Lift Transfer Unit

Accuracy with a Small Footprint

Lift Transfer Units move work piece pallets from one transport conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two, three, and four-way traffic control conditions.

Specifications

- Speed Range – 3.5 to 70 m/min

- Bi-directional operation

- Payload Capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm to 1040mm in 1mm increments

- Pallet width range – 160mm to 1040mm in1mm increments

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- 50mm bore lift cylinder

- 10mm lift stroke – 2mm below conveying surface to 8mm above conveying surface

- G1/8 ports

Features

- T5 timing style conveyor belts for positive drive

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Various bolt-on dampened stops available

- Guard package

- 24VDC enclosed drive system

- Additional DC drive options including control cards

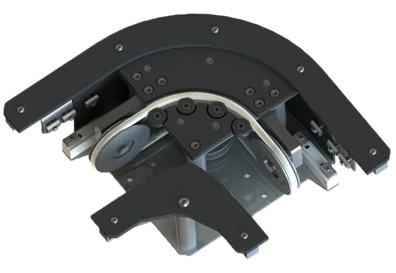

Curve Conveyor

Smooth Pallet Curving

Glide-Line curves are a mechanism to change the direction of a pallet. Pallets are conveyed around the curves by means of a solid, round urethane belt that is driven on v-groove pulleys. Small idler pulleys follow the track to reduce friction and prevent wear and tear.

Due to the configurable nature of our systems, curves can be configured as options of 30, 45, 60, 90, and 180 degrees, other custom options are available upon request.

Tandem Curves:

One variation of a curve is a Tandem Curve which allow pallets to transfer to/from parallel conveyor lanes, maintaining the leading edge of the pallet as it travels. The unit provides an economical approach to lane transfers, and if slaved can save several drives required for a traditional solution. Gap between parallel conveyors can range between 45mm and 350mm in 1mm increments.

Specifications

- Curves are suitable for pallets with 1.5:1 length to width ratio

- Curves are suitable for pallets that are up to 400mm x 400mm

- Curves are suitable for loads up to 44 lbs (20 kg)

Features

Curves are typically slave driven off adjacent conveyor by extending the o-ring belt into the upstream or downstream conveyor. The upstream conveyor utilizes a power take off shaft through a secondary drive box on the main conveyor and this shaft drives the v-grooved o-ring belt pulley.

Options

- Self-powered curve options available upon request

- Various angles to suit your needs, configurable from 15 to 270 degrees

Pallet Stops

Fully Configurable Lift Positioning

affic handling demands of your application. They are broken into 4 general categories:

All stops can be configured to be pneumatically single or double acting, to stop work-piece pallets so an operation can be performed. Dampened Stops offer a pneumatic cushioning force to the work piece that slows the impact of the pallet against the stop. The cushioning force can be adjusted to suit specific application needs. Larger stops and higher cushioning forces are available upon request.

Anti-Rebound pallet stops can be utilized as a unidirectional stop gate to prevent pallets from moving if the conveyor belt reverses direction in the application.

Drop-Away pallet stops are designed to work at an LTU (Lift and Transfer Unit) intersection where pallets are required to traverse in multiple directions.

Specifications

- Flexibility in the design and can also accomplish the same result with the lift and position kit (minus the cross bars).

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion.

- Standard stroke lift range 1mm to 200mm

- Short stroke lift range 1mm to 75mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm.

- 40mm bore lift cylinder.

- Lift capacity – 150 Lbs. @ 80 psi.

- Pallet length range – 160mm – 1040mm in 1mm increments.

- Pallet width range – 160mm – 1040mm in 1mm increments.

- G1/8 ports

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- Mid and High tolerance locating pins available