Pallet Transport Conveyor

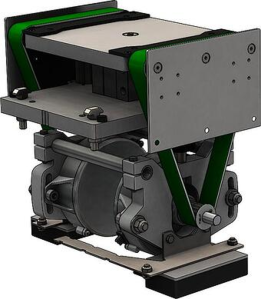

Twin Strand Pallet Conveying

The Twin Strand Transport Conveyor is a material handling solution of two or more strands, transporting panel-like products or large, platform-type fixtures from workstation to workstation. With the addition of our Roller Lift Transfer Unit, transport conveyors can be connected in many ways to suit a variety of assembly system requirements.

Videos

Specifications

- Speed Range – 3.5 to 70 m/min based on a 1750 motor RPM

- Transport Payload Capacity – 250 Lbs. per strand

- Minimum Strand length – 174mm

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- Extruded aluminum construction with standard 10mm T-slots

Features

- T5 timing style conveyor belts for positive drive and precision positioning ability

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Certified for use in clean room environments

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- All maintenance operations including belt changes can be performed from the top eliminating the need to disassemble or remove ancillary equipment

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Configurable cross-members – Define the number and position of cross-members desired

- Configurable break points – Define break points in the frame for convenient assembly and breakdown

- Belt covering – All belt cores are polyurethane with steel tension members

- Green polyamide covering (Nylon Fabric)

- Black antistatic polyamide covering (Nylon fabric with antistatic additives)

- White uncovered – Used for non-accumulating and cleanroom applications

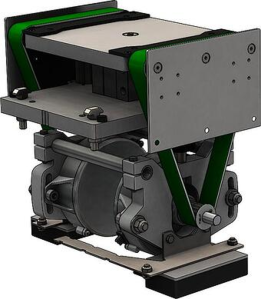

Lift Transfer Unit

Accuracy with a Small Footprint

Lift Transfer Units move work piece pallets from one transport conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two, three, and four-way traffic control conditions.

Videos

Specifications

- Speed Range – 3.5 to 70 m/min

- Bi-directional operation

- Payload Capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm to 1040mm in 1mm increments

- Pallet width range – 160mm to 1040mm in1mm increments

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- 50mm bore lift cylinder

- 10mm lift stroke – 2mm below conveying surface to 8mm above conveying surface

- G1/8 ports

Features

- T5 timing style conveyor belts for positive drive

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Various bolt-on dampened stops available

- Guard package

- 24VDC enclosed drive system

- Additional DC drive options including control cards

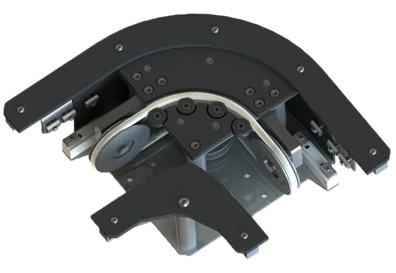

Curve Conveyor

Smooth Pallet Curving

Glide-Line curves are a mechanism to change the direction of a pallet. Pallets are conveyed around the curves by means of a solid, round urethane belt that is driven on v-groove pulleys. Small idler pulleys follow the track to reduce friction and prevent wear and tear.

Due to the configurable nature of our systems, curves can be configured as options of 30, 45, 60, 90, and 180 degrees, other custom options are available upon request.

Tandem Curves:

One variation of a curve is a Tandem Curve which allow pallets to transfer to/from parallel conveyor lanes, maintaining the leading edge of the pallet as it travels. The unit provides an economical approach to lane transfers, and if slaved can save several drives required for a traditional solution. Gap between parallel conveyors can range between 45mm and 350mm in 1mm increments.

Videos

Specifications

- Curves are suitable for pallets with 1.5:1 length to width ratio

- Curves are suitable for pallets that are up to 400mm x 400mm

- Curves are suitable for loads up to 44 lbs (20 kg)

Features

Curves are typically slave driven off adjacent conveyor by extending the o-ring belt into the upstream or downstream conveyor. The upstream conveyor utilizes a power take off shaft through a secondary drive box on the main conveyor and this shaft drives the v-grooved o-ring belt pulley.

Options

- Self-powered curve options available upon request

- Various angles to suit your needs, configurable from 15 to 270 degrees

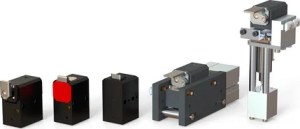

Pallet Stops

Fully Configurable Lift Positioning

Glide line offers a wide variety of pallet stops to suit the traffic handling demands of your application. They are broken into 4 general categories:

- Dampened Pallet Stops

- Non-Dampened Pallet Stops

- Anti-Rebound Pallet Stops

- Drop-Away Stops

Videos

All stops can be configured to be pneumatically single or double acting, to stop work-piece pallets so an operation can be performed. Dampened Stops offer a pneumatic cushioning force to the work piece that slows the impact of the pallet against the stop. The cushioning force can be adjusted to suit specific application needs. Larger stops and higher cushioning forces are available upon request.

Anti-Rebound pallet stops can be utilized as a unidirectional stop gate to prevent pallets from moving if the conveyor belt reverses direction in the application.

Drop-Away pallet stops are designed to work at an LTU (Lift and Transfer Unit) intersection where pallets are required to traverse in multiple directions.

Specifications

- Flexibility in the design and can also accomplish the same result with the lift and position kit (minus the cross bars).

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion.

- Standard stroke lift range 1mm to 200mm

- Short stroke lift range 1mm to 75mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm.

- 40mm bore lift cylinder.

- Lift capacity – 150 Lbs. @ 80 psi.

- Pallet length range – 160mm – 1040mm in 1mm increments.

- Pallet width range – 160mm – 1040mm in 1mm increments.

- G1/8 ports

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- Mid and High tolerance locating pins available

Downloads

Pallet Transport Conveyor

Twin Strand Pallet Conveying

The Twin Strand Transport Conveyor is a material handling solution of two or more strands, transporting panel-like products or large, platform-type fixtures from workstation to workstation. With the addition of our Roller Lift Transfer Unit, transport conveyors can be connected in many ways to suit a variety of assembly system requirements.

Specifications

- Speed Range – 3.5 to 70 m/min based on a 1750 motor RPM

- Transport Payload Capacity – 250 Lbs. per strand

- Minimum Strand length – 174mm

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- Extruded aluminum construction with standard 10mm T-slots

Features

- T5 timing style conveyor belts for positive drive and precision positioning ability

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Certified for use in clean room environments

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- All maintenance operations including belt changes can be performed from the top eliminating the need to disassemble or remove ancillary equipment

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Configurable cross-members – Define the number and position of cross-members desired

- Configurable break points – Define break points in the frame for convenient assembly and breakdown

- Belt covering – All belt cores are polyurethane with steel tension members

Lift Transfer Unit

Accuracy with a Small Footprint

Lift Transfer Units move work piece pallets from one transport conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two, three, and four-way traffic control conditions.

Specifications

- Speed Range – 3.5 to 70 m/min

- Bi-directional operation

- Payload Capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm to 1040mm in 1mm increments

- Pallet width range – 160mm to 1040mm in1mm increments

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- 50mm bore lift cylinder

- 10mm lift stroke – 2mm below conveying surface to 8mm above conveying surface

- G1/8 ports

Features

- T5 timing style conveyor belts for positive drive

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- Highly configurable

- Bolt-up compatibility with other leading brands

Options

- Various bolt-on dampened stops available

- Guard package

- 24VDC enclosed drive system

- Additional DC drive options including control cards

Curve Conveyor

Smooth Pallet Curving

Glide-Line curves are a mechanism to change the direction of a pallet. Pallets are conveyed around the curves by means of a solid, round urethane belt that is driven on v-groove pulleys. Small idler pulleys follow the track to reduce friction and prevent wear and tear.

Due to the configurable nature of our systems, curves can be configured as options of 30, 45, 60, 90, and 180 degrees, other custom options are available upon request.

Tandem Curves:

One variation of a curve is a Tandem Curve which allow pallets to transfer to/from parallel conveyor lanes, maintaining the leading edge of the pallet as it travels. The unit provides an economical approach to lane transfers, and if slaved can save several drives required for a traditional solution. Gap between parallel conveyors can range between 45mm and 350mm in 1mm increments.

Specifications

- Curves are suitable for pallets with 1.5:1 length to width ratio

- Curves are suitable for pallets that are up to 400mm x 400mm

- Curves are suitable for loads up to 44 lbs (20 kg)

Features

Curves are typically slave driven off adjacent conveyor by extending the o-ring belt into the upstream or downstream conveyor. The upstream conveyor utilizes a power take off shaft through a secondary drive box on the main conveyor and this shaft drives the v-grooved o-ring belt pulley.

Options

- Self-powered curve options available upon request

- Various angles to suit your needs, configurable from 15 to 270 degrees

Pallet Stops

Fully Configurable Lift Positioning

affic handling demands of your application. They are broken into 4 general categories:

All stops can be configured to be pneumatically single or double acting, to stop work-piece pallets so an operation can be performed. Dampened Stops offer a pneumatic cushioning force to the work piece that slows the impact of the pallet against the stop. The cushioning force can be adjusted to suit specific application needs. Larger stops and higher cushioning forces are available upon request.

Anti-Rebound pallet stops can be utilized as a unidirectional stop gate to prevent pallets from moving if the conveyor belt reverses direction in the application.

Drop-Away pallet stops are designed to work at an LTU (Lift and Transfer Unit) intersection where pallets are required to traverse in multiple directions.

Specifications

- Flexibility in the design and can also accomplish the same result with the lift and position kit (minus the cross bars).

- Station or conveyor mounted.

- Hydraulic shock absorbers for vertical motion.

- Standard stroke lift range 1mm to 200mm

- Short stroke lift range 1mm to 75mm

- Precision lift height adjustment +/- 10mm

- Lateral and vertical location repeatability within .05mm.

- 40mm bore lift cylinder.

- Lift capacity – 150 Lbs. @ 80 psi.

- Pallet length range – 160mm – 1040mm in 1mm increments.

- Pallet width range – 160mm – 1040mm in 1mm increments.

- G1/8 ports

Features

- Pneumatic lift actuation.

- Station or conveyor mounted.

Options

- Guard package

- Mid and High tolerance locating pins available