- The Systems

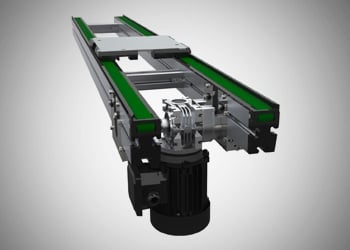

- Conveyor Solutions

- Glide-Line Devices & Accessories

- Glide-Line's Zero Contact Zoned Conveyor

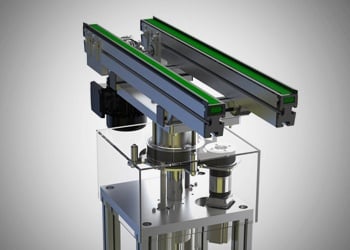

- Glide-Line 360 Unlimited Solutions

- Customized Solutions Gallery

- VTU Solutions

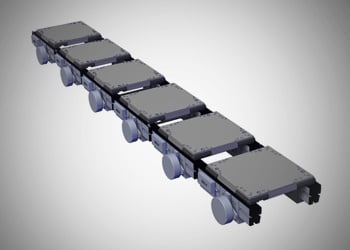

- Conveyors for AMRs

- The Software

- About

- Resources

- Blog

- Contact Us