Blog

View our latest guides and success stories

The Benefit of Flexible Conveyor Workstations for Manufacturing

Read More… from The Benefit of Flexible Conveyor Workstations for Manufacturing

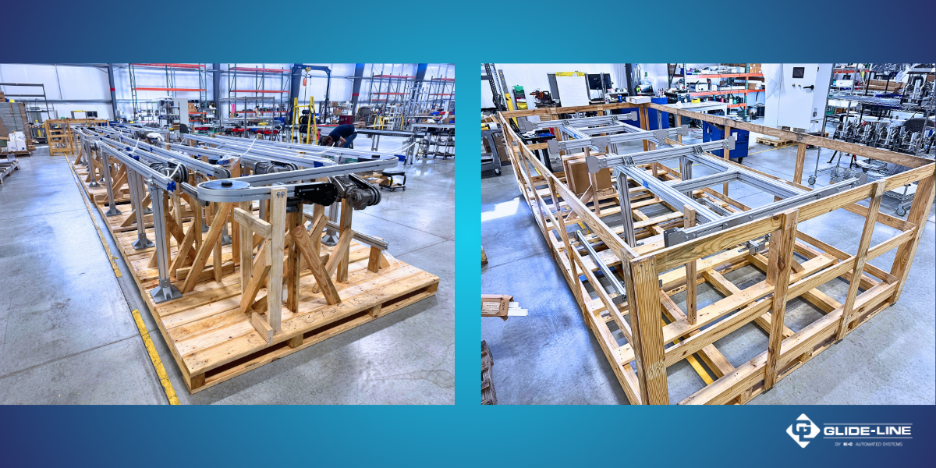

The Pre-Assembled Advantage: Why Integrators Profit More with Glide-Line

Read More… from The Pre-Assembled Advantage: Why Integrators Profit More with Glide-Line

Why Smart Manufacturers Choose Timing Belt Conveyors for Precision & Flexibility

Read More… from Why Smart Manufacturers Choose Timing Belt Conveyors for Precision & Flexibility

The Environmental and Economic Benefits of Modern Industrial Conveying Systems

Read More… from The Environmental and Economic Benefits of Modern Industrial Conveying Systems

Zone-Controlled Conveying: Why Intelligent Conveyors Are the Future

Read More… from Zone-Controlled Conveying: Why Intelligent Conveyors Are the Future

Smooth Conveyor Transfer for Delicate Photovoltaic Cells and Solar Panels

Read More… from Smooth Conveyor Transfer for Delicate Photovoltaic Cells and Solar Panels

Traffic Control Conveyor Solutions for Direct Material Handling

Read More… from Traffic Control Conveyor Solutions for Direct Material Handling

Irregularly Shaped Products Are Hard to Convey Without a Zero Contact Zoned Conveyor

Read More… from Irregularly Shaped Products Are Hard to Convey Without a Zero Contact Zoned Conveyor

How to Better Convey a Solar Panel for Increased Production Capacity

Read More… from How to Better Convey a Solar Panel for Increased Production Capacity

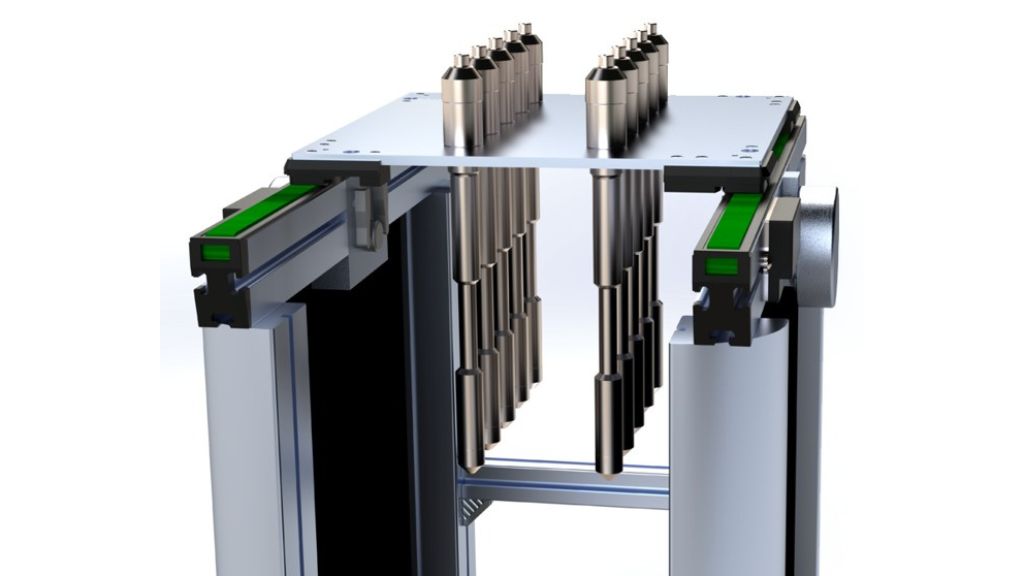

Why is the Zero Contact Zoned Conveyor A Popular Conveyor Solution?

Read More… from Why is the Zero Contact Zoned Conveyor A Popular Conveyor Solution?

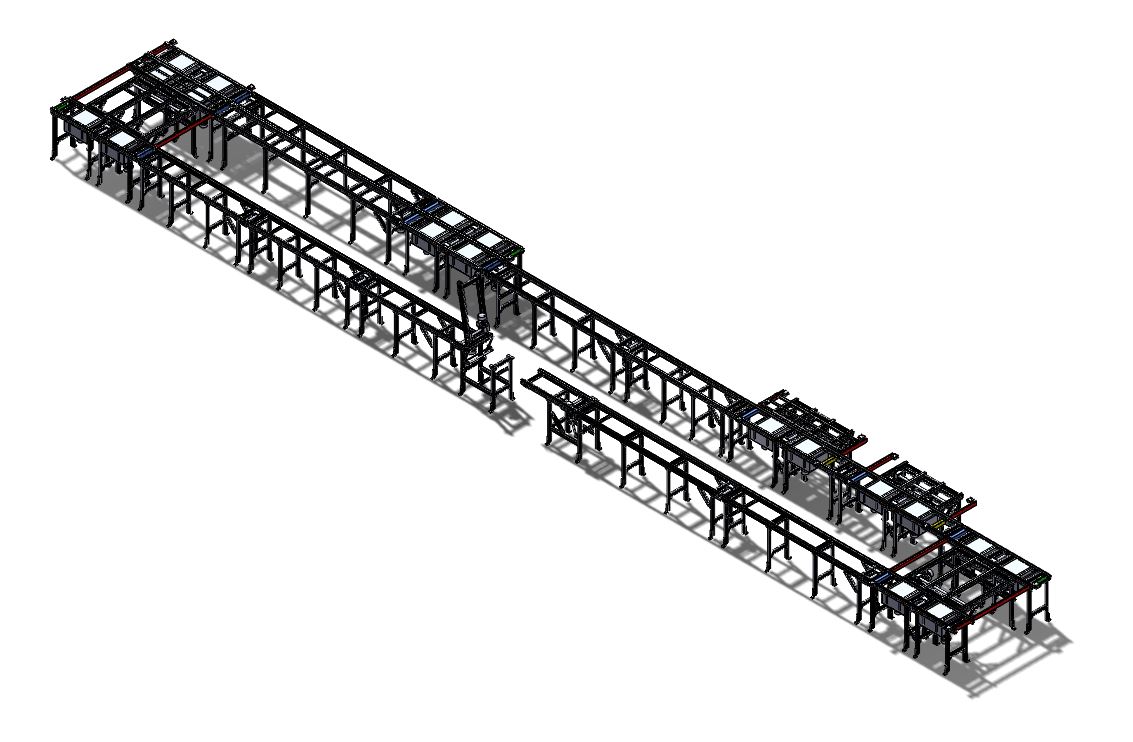

Roller Chain Conveyors with Flexible Configuration

Read More… from Roller Chain Conveyors with Flexible Configuration

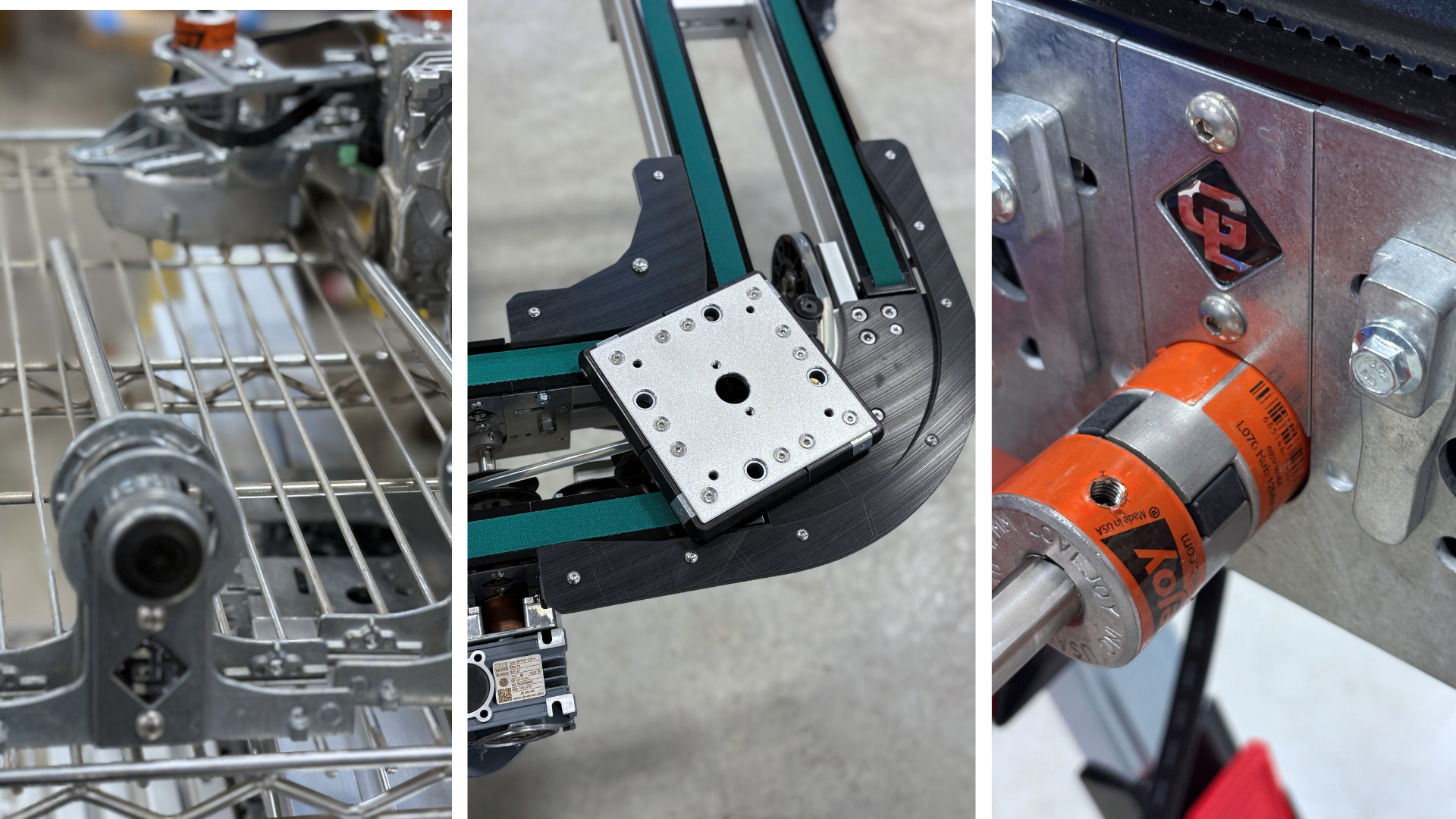

Working with Glide-Line is Fast, Flexible & Easy

Read More… from Working with Glide-Line is Fast, Flexible & Easy

Register Your IMPACT! Software Now

By registering your copy of Impact!, you will receive instructions that will allow you to download the latest pricing and pre built templates to ensure the most accurate up to date pricing, and will be apprised of all developments and updates to the software.