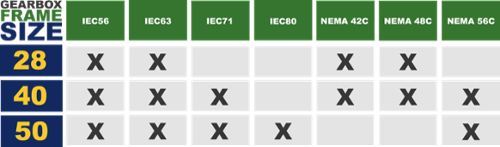

Flexibility in conveyor design is one of the biggest reasons our integrator customers choose Glide-Line. That goes for use of motors, gearboxes, and controls, as well.

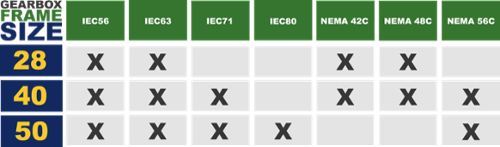

We offer a great variety in our gearbox flange options, allowing our customers to utilize a wide range of motor frame sizes. Whether you have a specification from your customer who prefers to standardize motors across their plant, or they’re using other equipment that requires a specific motor brand and frame size, we offer great flexibility in this regard.

While any conveyor manufacturer can ship a conveyor less motor and gearbox to allow for flexibility in power transmission, we actually ship a gearbox with several different flange adapters, allowing for integration of both IEC (metric) and NEMA motor frame sizes.