- Why Glide-Line

- Hardware Systems

- Conveyor Solutions

- Glide-Line Devices & Accessories

- Glide-Line's Zero Contact Zoned Conveyor

- Glide-Line 360 Unlimited Solutions

- Customized Solutions Gallery

- VTU Solutions

- Conveyors for AMRs

- Software Solutions

- About

- Resources

- Blog

- Videos

- Contact

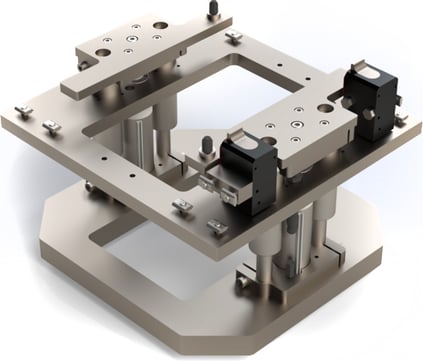

The Open Center Lift and Locate Unit offers fully configurable vertical lift positioning, and it is suitable for applications that require repeatable, positional accuracy within ±.05mm. The unit can be station-mounted or mounted directly to the transport conveyor; accuracy and repeatability are relative to the mounting structure.

The Open Center Lift and Locate Unit offers fully configurable vertical lift positioning, and it is suitable for applications that require repeatable, positional accuracy within ±.05mm. The unit can be station-mounted or mounted directly to the transport conveyor; accuracy and repeatability are relative to the mounting structure.