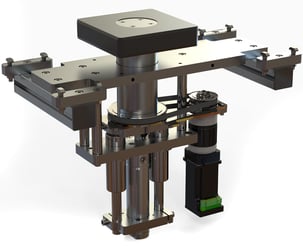

A lift and rotate unit is a standard, tried and true offering from traditional conveyor manufacturers. But Glide-Line has taken this standard offering and injected two doses of our signature creativity into the LRU to make it a flexible, creative solution in our modular conveyor automation lines.

First, we’re powering the Lift and Rotate Unit using a servo-driven motor, giving our integrator clients unlimited control and precision programming of the speed and rotational angles of the LRU.

First, we’re powering the Lift and Rotate Unit using a servo-driven motor, giving our integrator clients unlimited control and precision programming of the speed and rotational angles of the LRU.

Second, we’ve devised a creative use for the lift and rotate mechanism: a simple and effective bypass. Using the LRU, you’re able to lift pallets and place them on a shelf or ledge so other pallets can pass under the elevated pallet. This can be a cost-effective bypass solution in specific product instances.

Lift & Rotate Unit: Bypass Creation Example

Picture a square pallet. When it comes to an inspection station on the conveyor line, a Lift & Rotate Unit can elevate the pallet and rotate it 45º so the corners catch on a square-shaped ledge located above the main line. Additional pallets can continue moving under the elevated pallet. Once the pallet is ready to be re-engaged, the Lift & Rotate re-connects with the pallet, rotates it back 45º, and the pallet can continue down the line.

Instead of holding up the line to complete slower processes, building horizontally to create a jug handle bypass (adding expense and requiring extra floor space), or completing manual sequences to prevent delays, Glide-Line’s Lift and Rotate Unit can be applied in these situations to create a more cost-effective and cleaner bypass option.

Like many of our creative solutions, we devised this application for the Lift and Rotate Unit from a customer’s need. Our flexible modular conveyor mechanisms and lines are being used to constantly change the shape of the conveyor industry – since we refuse to be placed in a box and provide only one-size-fits-all solutions. Instead, we’re giving our integrator customers flexible solutions built from creative ideas.

Learn more in our new ebook, Thinking Differently: The Guide To Creatively Lift & Rotate Products in your Assembly Automation System.

Leave a Comment