Moving photovoltaic solar panels through an assembly line today is a delicate process that involves intricate movements, transfers, and rotations. Traditional systems may suffice when the product doesn’t rely on multiple assembly stages, or when it doesn’t require exact control during every step of the process. However, for relatively delicate wide products like solar panels, many manufacturing facilities are looking for a more economical conveyance solution that provides precise control and maximum configurability to help automate the processes for increased throughput – without compromising product quality.

Industry 4.0 is driving new growth in the material handling industry, and analysts expect the sector to grow to $9 billion in revenues by 2025. Economical conveyor systems will become the workhorses of all future manufacturing facilities. When the products involved in the process require special considerations, like a gentle photovoltaic system conveyor, you need superior configurability, versatility, and customization capabilities.

Modern Conveyor Systems Manufacturers Provide New Possibilities

Conveying systems have been helping improve manufacturing processes for more than two centuries. Today, almost every manufacturing facility needs some form of conveyance system and automation capability to transfer products between different workstations. While standard systems can work for standard material handling situations, specialized conveyor systems enable application engineers and facilities to automate many of the manufacturing processes when specialized or atypical sized materials are part of the process.

Conveying systems have been helping improve manufacturing processes for more than two centuries. Today, almost every manufacturing facility needs some form of conveyance system and automation capability to transfer products between different workstations. While standard systems can work for standard material handling situations, specialized conveyor systems enable application engineers and facilities to automate many of the manufacturing processes when specialized or atypical sized materials are part of the process.

Here are some of the key benefits available from today’s multi-strand economical material conveyor systems.

Economical Multi-Strand Material Conveyor Systems

Economical Multi-Strand Material Conveyor Systems

Application engineers need to move product through multiple stages, across an assembly platform, while conveying products directly. Specialized needs in photovoltaic could be standard transportation, specialized product conveyance. It could also include manipulating products, requiring special AMR robots, rotations, and specialized handling machines that provide precise movements during every step of the assembly line.

Application engineers need to move product through multiple stages, across an assembly platform, while conveying products directly. Specialized needs in photovoltaic could be standard transportation, specialized product conveyance. It could also include manipulating products, requiring special AMR robots, rotations, and specialized handling machines that provide precise movements during every step of the assembly line.

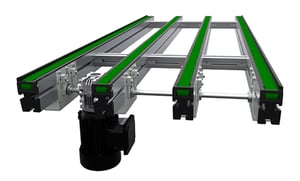

Multi-strand direct product handling conveyor systems are ideal for solar panels, as you can easily:

- Configure a custom conveyor system that gently moves products between different workstations

- Lift, rotate, and move products throughout the facility, including vertical transfers and bypasses

- Create transfer bridges and interface points for seamless movement on the assembly line

- Design Zero Contact Zoned Conveyor systems to handle delicate photovoltaic cells and panels directly on the belt

Customize Guides and Extrusions for Any Product Size or Shape

Customize Guides and Extrusions for Any Product Size or Shape

Application engineers understand that once you need to go wider, you start upsetting the budget. Roller-based systems become cost-prohibitive when you create the widths required for solar panels.

When handling wider products, it is usually best to use a system that can handle products of any width by simply expanding the system using additional strands, instead of building wider rollers. It is simply more cost effective.

When handling wider products, it is usually best to use a system that can handle products of any width by simply expanding the system using additional strands, instead of building wider rollers. It is simply more cost effective.

Multi-strand conveyor systems are driven by common shafts, and you can include lifts, transfers, and storage racks as required. On standard belt conveyors, the product could suffer from scrap rates and product scuffs or marring, which multi-strand conveyors can reduce with less friction using a low coefficient on the belts, or even zoning. You can use the same design principles to scale your system for solar panel conveyance and improve your productivity. Today’s conveyor systems manufacturers can take any concept and deliver a workable, efficient, and precise transportation system for any wide products.

Handling Product Orientation, Presentation, and Access

Handling Product Orientation, Presentation, and Access

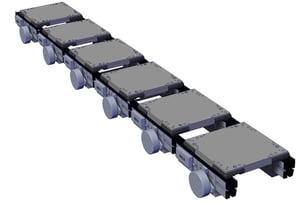

By using a base configuration of timing belt-based multi-strand economical material conveyor systems, your product manipulation capabilities improve drastically. When cost, configurability, and direct material handling systems for wide or atypical products are required, multi-strand conveyors deliver precise control and product manipulation during the assembly and manufacturing process.

You also get a reliable conveyor system that provides exact orientation, presentation, and access to the frames, solar panels, or plate-glass products across the line. For photovoltaic panel manufacturing, the vibration and pressure could have an impact on the product’s quality. Multi-strand conveyor systems provide better cushion capabilities and with Glide-Line’s Zero Contact Zoned Conveyors for material handling, you get a gentler, more cost-effective solution compared to a traditional belt or chain systems. With the Zero Contact Zoned system, there is no product-to-product contact on the conveyor system.

Automate Your Manufacturing Process with Glide-Line

With Glide-Line, you can configure a solar panel conveyor system that automates most of your material handling processes throughout the assembly line. Using the multi-strand conveyor as the base system, we’re able to add configurations that are standard to us, which allows you to orientate, position, and transfer wide products seamlessly. The Zero Contact Zoned Conveyor solution ensures your solar panels don’t collide or touch during transportation through the assembly line.

With Glide-Line, you can configure a solar panel conveyor system that automates most of your material handling processes throughout the assembly line. Using the multi-strand conveyor as the base system, we’re able to add configurations that are standard to us, which allows you to orientate, position, and transfer wide products seamlessly. The Zero Contact Zoned Conveyor solution ensures your solar panels don’t collide or touch during transportation through the assembly line.

We can assist with any kind of customized situation and help you transport a solar panel more efficiently, including:

- Vertical Transfer Units (VTUs) help save space by utilizing the vertical space in your production area

- Centerline adjustable conveyors, including configurable width guide rails while helping save space

- Vertical Transfer Units (VTUs) feeding rack systems and other storage devices that reduce operator involvement for greater cost savings

- Transfer bridges, Zero Contact Zoned Conveyors, tilting decks, bypass lifts, and direct product conveyors for delicate solar panel handling during manufacturing

Glide-Line provides flexible conveyor solutions for pallet and direct product handling operations, including wide, atypical, and fragile products like solar panels. Our engineers can design, configure, and customize solutions that automate your assembly or manufacturing process. With IMPACT!, our 3D CAD configurator, you can build your conveyor and generate instant pricing, including a parts list. Streamline how you convey solar panels and cells in your assembly operations using Glide-Line’s range of conveying solutions. Glide-Line will help keep your team happy and put a smile on the production manager’s face.

To discuss your needs with our conveyor systems manufacturers and application engineers, get in touch with Glide-Line today.

Leave a Comment