There’s a reason we still use wood for manufacturing most of our furniture.

It’s a sustainable resource, comes in many different strengths and weights, and it’s good for the environment.

However, when you’re moving wide furniture through assembly operations that also require elevation changes, the process may not be as straightforward as it used to be. For one thing, you can no longer expect your operators to just lift with their legs.

The steady adoption of modern manufacturing principles and ergonomics in the furniture industry is making today’s wood factories just as smart as any other assembly line. With the right material handling technologies and conveying equipment, it’s possible to automate many of the product manipulation tasks and spare your craftspeople a lot of time and physical effort.

Although Nick Offerman may prefer to work with his hands when making furniture, we respectfully disagree.

With Glide-Line’s material handling conveyors and flexible manufacturing solutions, you get the best of both worlds. You can streamline assembly operations while giving the required access to your operators at the elevation required for each task. Here’s how:

Conveying and Elevating Wide Furniture Using Flexible Manufacturing and Material Handling Technologies

Wide furniture pieces present unique challenges during the manufacturing process. Although value-added wood furniture products increase their raw material value by up to 30 times, the same economical and safety considerations will apply to your assembly line.

Pieces need to go through different process stages to work the raw material into the required shape before joining items and traveling through finishing operations. Each stage may require a different orientation, elevation, or rotation to perform the work safely and ergonomically.

Glide-Line’s range of material handling conveyors provides you with a base system that turns your assembly operations into an Industry 4.0 facility. The added benefit is wherever you need to add that extra level of detail, our programmable lift locates, rotates, and vertical transfers will ensure your workers have the necessary access and workpiece manipulation capabilities.

Workpiece Storage and Retrieval using a Vertical Transfer Unit

Just because you’re working with wide furniture products doesn’t mean you need massive pieces of equipment to transfer items vertically on the assembly line. A customized vertical transfer unit can accommodate any product dimension while smoothly moving workpieces to different elevations and conveyor sections. You can even move pieces between floors and automate your storage and retrieval tasks.

Just because you’re working with wide furniture products doesn’t mean you need massive pieces of equipment to transfer items vertically on the assembly line. A customized vertical transfer unit can accommodate any product dimension while smoothly moving workpieces to different elevations and conveyor sections. You can even move pieces between floors and automate your storage and retrieval tasks.

A vertical transfer unit enables you to:

- Customize the base system to accommodate multiple stops, elevation changes, or conveying decks

- Design a solution that can handle your product dimensions and weights without taking up unnecessary floor space

- Integrate vertical lifts at any point in your assembly operation to provide workers with safe and ergonomic access to workpieces

Locating and Lifting Workpieces for Assembly Operations

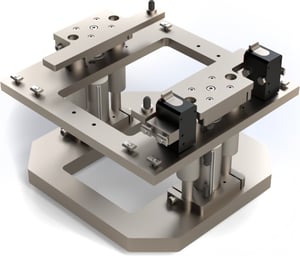

When you need precision control while elevating wide furniture above the line, a lift and locate unit lets you position a workpiece for any external operation, exactly. We have a range of designs including standard lift, locates, or heavy-duty units for heavier workpieces.

For precise lifting of workpieces above the line, our lift and locate units can:

- Lift a workpiece within an accuracy of +/- 0.05mm between 3 and 200mm increments

- Customize a solution that accommodates your exact application requirements for the assembly operation you need to perform

- Give your operators access to workpieces using an open center lift and locate design that integrates seamlessly with your multi-strand conveyor system

Drop and Rotate Wide Furniture on the Conveyor Line

When you need to manipulate pieces on the line and control either the orientation, elevation, or rotation of an item, our drop and rotate transfer units act as a centralized distribution hub. We designed the solution to save on space while providing you with an economical way to solve complex workpiece handling and distribution applications.

When you need to manipulate pieces on the line and control either the orientation, elevation, or rotation of an item, our drop and rotate transfer units act as a centralized distribution hub. We designed the solution to save on space while providing you with an economical way to solve complex workpiece handling and distribution applications.

Our drop and rotate transfer units let you:

- Manage complex distribution challenges in a small footprint

- Deploy a greater level of automation for all your workpiece elevation and rotation changes

- Drop, rotate, and transfer heavier workpieces to an external station for assembly operations

Support Your Assembly Operations and Workers With Material Handling Technologies from Glide-Line

At Glide-Line, we pride ourselves on our ability to solve complex assembly operations for any kind of workpiece or direct product handling requirement. Our solutions operate with the required precision and give you smooth control over the entire assembly line even when conveying vertically, helping to reduce damage and increase worker safety.

We also have the shortest lead times in the industry and you can start designing a system by downloading our SolidWorks-integrated IMPACT! Configurator right now.

For more information about our solutions or if you want to see how we can merge your operations with automated elevation solutions, speak to a Glide-Line expert today.

Leave a Comment