Upsizing conveyor components is the norm when conveying large or relatively heavy products. For items such as airplane wings and auto parts, this can be the most effective material handling solution. But traditional conveyor accumulation techniques can give way to product damage.

The traditional solution to accumulating larger products has been to simply upside the conveyor design, and retain the traditional accumulation technique of running the conveyor all day, putting product on pallets, and then managing traffic with pneumatic stops. While there is nothing wrong with that, there is another solution. This solution is more elegant, requires less wear and tear, and is ideal for handling products without a pallet or that can’t tolerate constant collisions and bumps associated with traditional methods.

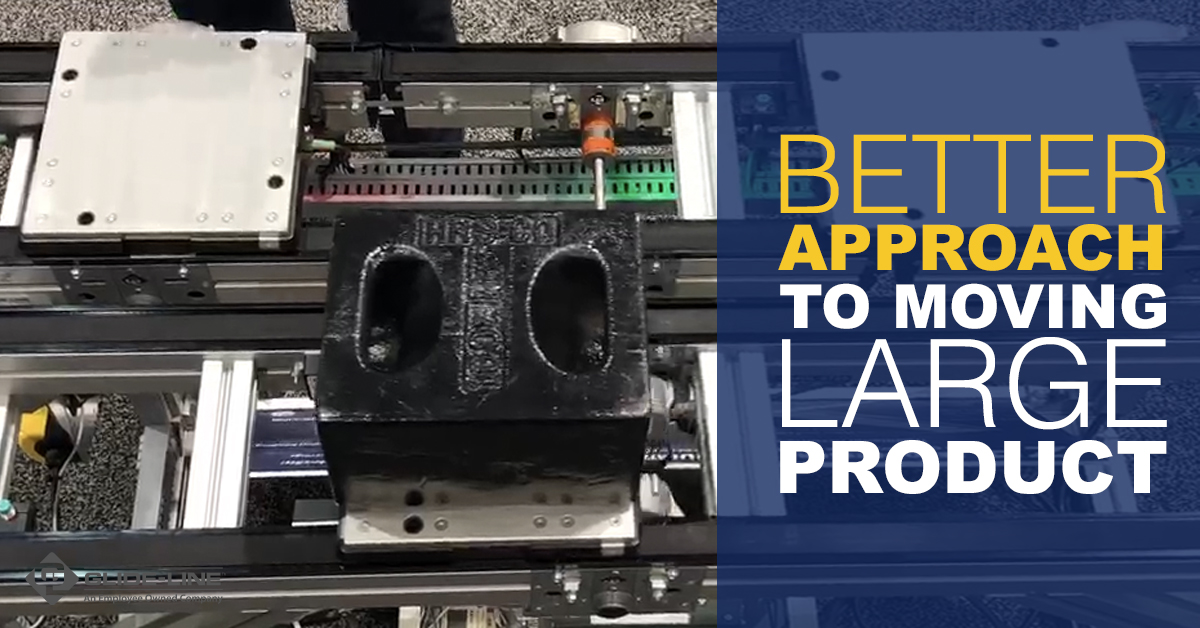

Glide-Line’s Zero Contact Zoned Conveyor solution could be the right alternative. With our zoned conveyors, you can build a system better suited for the safe handling of large, expensive products. By building a more elegant solution, you can improve handling, and reduce damage.

A Better Approach To Moving Large Product

Traditional conveyor techniques can be effective. But they give way to tremendous product damage risks. This is especially the case with stops. Typical methods utilize hard stops. The product hits the stop, without any gradual deceleration. Subsequent products bang into the stopped product. These impacts over time can cause damage to the products being handled and create a lot of wasted energy as well as wear and tear.

With the Zero Contact Zoned Conveyor, these issues are eliminated. Instead of using a single belt, we used separately zoned conveyors. With products never touching each other, there is minimal risk of product damage. In addition, many (or all) stops along the way utilize a sensor that turns zones on and off by means of local, embedded zero contact logic. The conveyor gradually decelerates to the stopping point. Subsequent conveyors are directed to stop as well, preventing products from banging into each other.

With this refined design, a Zero Contact-oriented conveyor is a more elegant alternative to simply upsizing components. This alternative eliminates the myriad of risks inherent with traditional conveyance techniques. By ensuring products never touch each other, and by using a smarter method of controlled movement, the issue of product damage disappears.

Glide-Line Can Customize A Solution To Meet Your Needs

Customization is key when building the right conveyor system design. Especially when it comes to developing customized Zero Contact Zoned Conveyor accumulation systems as we frequently customize our solution to fit the needs of your end-user (depending on their product and application).

Not only can we help you choose the right conveyor solution, we can help you configure it in half the lead time of our competitors. You can also configure it yourself, using our IMPACT! configuration software. With many options, Glide-Line is a strong choice for developing upsizing alternatives.

Want to Learn More? Check out our FREE eBook, How To Manage Conveyor Accumulation Issues.

Leave a Comment