Glide-Line offers a wide variety of Pallet Stop mechanisms to suit the traffic handling demands of your clients’ applications. We offer three types:

All stops can be configured to be pneumatically single- or double-acting. With a pneumatic stop in place, the workpiece pallet is located to a position for either traffic control or so an operation can be performed.

Why Choose Glide-Line’s Pallet Stops

1. Configurable Sizes, Positioning, and Control

Glide-Line’s pallet stops are sized and positioned according to the application and your client’s needs; both are completely configurable. The limitation is the overall weight and speed of the product on the conveyor; if the maximum force is exceeded, we simply add an additional stop to accommodate.

Our standard dampened stops support up to 60kg each, while the non-dampened stops can support up to 400kg each. Since our conveyors will never exceed a 400kg load, the only limitation is on the dampened stop. If we exceed 60kg using one dampened stop, we can simply add an additional stop to increase our load capacity to 120kgs.

For systems moving larger pallets, we typically add a second pallet stop to help keep the pallet square on the conveyor line; we’ve found that using only one can jar a larger pallet, and we know maintaining pallet control is important to our customers’ clients.

You can also add pallet stop locations on both the leading and trailing edges of the pallets, mounted to the conveyor strand, enabling flexibility in the case of an obstruction on one side or the other.

2. Reduced Wear and Tear on Pallets

Glide-Line’s pallet stops cause less wear and tear on the pallet when they interact with the pallet (particularly the non-dampened stops) than our competitors’ stops. Because of the geometry and material used in the pallet stops, there is less wear on the pallets and they hold up better.

3. Flexibility

Glide-Line offers all our standard stops in a variety of configurations and options. Popular configurations include "double-acting" and "electronic sensing capable" stops. Double-acting stops allow for pneumatic control of actuation and de-actuation, instead of relying on a spring for return. Electronic sensing capable stops allow the use of electronic sensors to detect both actuated and de-actuated positions.

4. Easy Installation Anywhere

Glide-Line’s pallet stops can be added anywhere along a conveyor line; there are very few restrictions on placement for mounting the stops. They are also easy to install; Glide-Line ships all parts disassembled and clients are able to easily mount the stop anywhere it’s needed within the process.

Challenges Solved by Glide-Line’s Pallet Stops

Traffic Control

Anti-Rebound Pallet Stops can be utilized as unidirectional stop gates to prevent pallets from moving if the conveyor belt reverses direction in the application. Once a pallet passes over the anti-rebound stop, it can never go backward over it (think ratchet and pawl).

Anti-Rebound Pallet Stops can be utilized as unidirectional stop gates to prevent pallets from moving if the conveyor belt reverses direction in the application. Once a pallet passes over the anti-rebound stop, it can never go backward over it (think ratchet and pawl).

This pallet stop is used to prevent backward flow on a bi-directional conveyor. For example, if your client has two pallets and one needs to move the opposite direction, this pallet stop prevents them both from moving; one stays in place thanks to the anti-rebound pallet stop. A pneumatic actuated version of this stop is also available.

Proximity control sensors also enable excellent control over pallet locations. Once the device is clear from the sensor, the stop will de-actuate and allow the next pallet to go through.

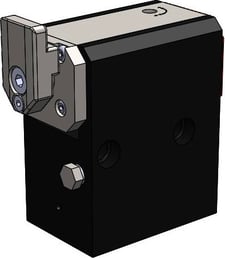

Impact Absorption

Dampened Pallet Stops are equipped with a pneumatic damper to absorb the impact of the pallet against the stop. The cushion force can be adjusted to meet demands of a specific application. It starts out in the advanced position, then absorbs the force and becomes “depressed”. The dampened stops can be sized for various load weights; 60kg is standard (140 pounds), but the weight load can go up to 120kg. These are especially useful to prevent product damage from heavy pallets; the dampened pallet stops work with conveyors to give extra control over potential impact.

Dampened Pallet Stops are equipped with a pneumatic damper to absorb the impact of the pallet against the stop. The cushion force can be adjusted to meet demands of a specific application. It starts out in the advanced position, then absorbs the force and becomes “depressed”. The dampened stops can be sized for various load weights; 60kg is standard (140 pounds), but the weight load can go up to 120kg. These are especially useful to prevent product damage from heavy pallets; the dampened pallet stops work with conveyors to give extra control over potential impact.

Dampened Pallet Stops include self-adjusting damping (manual adjustment is also available). Additional options include heat and cold resistance, position sensors, and a 13mm lowering stroke. Learn more here.

Cost Effectiveness

Cost Effectiveness

If your client is using lighter pallets with products that are not fragile, a cost-effective option is a Non-Dampened Pallet Stop. Non-Dampened Pallet Stops prevent one or more accumulated workpiece pallets at a defined stop plate in conveyor systems. As the pallet comes toward the stop, the cylinder is lifted up pneumatically and the stop blade comes up with the cylinder to stop the pallet.

Pallet Queuing

Pallet queuing can be accomplished using any of our pallet stops. By using pallet stops at the operator stations to stop the pallets and/or queue up the pallets to work on, manual operations are easy and accurate.

Accumulating Lines

On conveyors where belts are constantly running, a client can use stops to prevent the product from moving forward. Many times the stops in this instance are used with proximity sensors; we provide stop-sensor brackets that can be mounted to the pallet. The pallet has an “exciter plate” that is used with the proximity sensor. It senses the location and pneumatically actuates the stop.

Location Repeatability

Once you mount the stop, your client is able to stop the pallet at that position every time. This enables a great deal of control and repeatability in locating the pallet reliably.

Glide-Line’s pallet stops can suit any traffic handling demands your clients may need. Learn more about our customized solutions here.

Leave a Comment