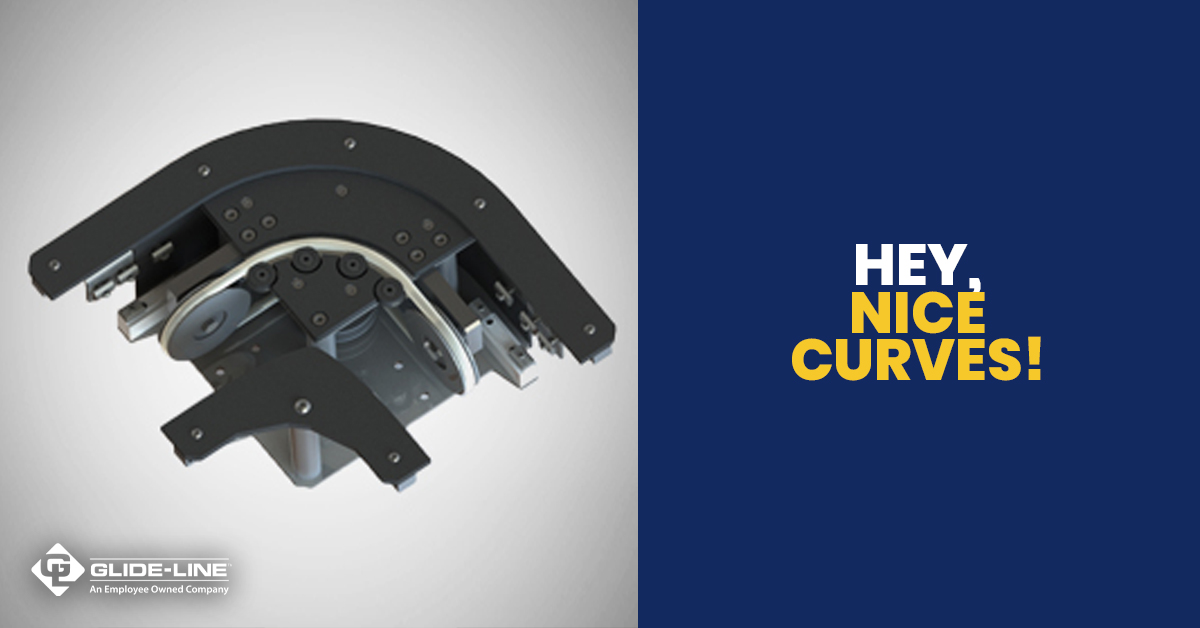

Curves are mechanisms designed to change the direction of a pallet within a conveyor line or system. Glide-Line offers a variety of angles:

- 90-degree Curves

- 45-degree Curves

- 180-degree/Tandem Curves

In fact, due to the configurable nature of Glide-Line’s systems, Curves can be configured in any angle from 15 to 270 degrees. The geometries of the outer and inner guides change with the curve angle required by your customer’s system.

How Our Curves Are Different

Curves are belt-driven by a solid, round urethane belt and guided with small v-groove pulleys and idler pulleys to reduce friction and prevent wear. We also offer one-degree increments in curves; our competitors lock you into 90-degree and 180-degree angles without high levels of customization.

Curves Solve Challenges

Glide-Line’s Curve mechanisms solve three distinct challenges for integrator clients:

- The Curve mechanism maintains pallet orientation; the same leading edge that comes into the curve is the first to leave - pallet orientation doesn’t change. The 90 curve allows you to change direction of the pallet without changing the leading edge orientation of the pallet.

- We can do unique curve angles at a standard (read: not increased) price or lead time.

- Curves are slave driven so they don’t require separate motors. Curves are typically slave driven off an adjacent conveyor by extending the o-ring belt into the upstream or downstream conveyor. The upstream conveyor utilizes a power take-off shaft through a drive box (primary or secondary) on the main conveyor and this shaft drives the v-grooved o-ring belt pulley.

Curve Specs

Curves are typically suitable for pallets with 1.5:1 length to width ratio up to 400mm x 400mm. We have many different solutions for longer pallets so the pallets don’t get stuck on the outer guides. The Curve is suitable for loads up to 20 kilograms.

Curves are typically slave driven off the upstream or downstream conveyor, removing the need for an independent drive and reducing the overall number of motors. There is no need for an extra drive mechanism to power the curve.

Most appealing to our clients is the low cost of Glide-Line’s Curve mechanism compared to a Lift & Transfer Unit that could also be used to accomplish the motion around a corner; comparatively, the Curve is about half the cost.

Learn more about the Curve mechanism from Glide-Line and contact us today to see how this addition can help meet your toughest conveyor line challenges.

Leave a Comment