Pallet accumulation leads to rough product handling that can compromise the integrity and quality of products being accumulated as well as lead to additional wear and tear.

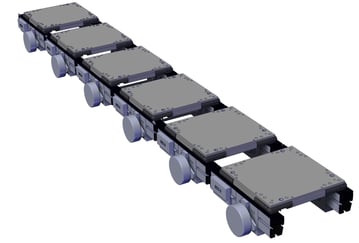

Accumulation is a necessary part of many asynchronous assembly processes. But when pallets bang into each other, get dislodged in their fixtures, or otherwise get damaged on the conveyor line, you need to find a solution!That’s why we created the Zero Contact Zoned Conveyor. With the innovative design of the Zero Contact Zoned Conveyor, we’ve helped conveyor and automation system engineers design systems to gently move all types of products.

Keep on reading to learn why the Glide-Line's Zero Contact Zoned Conveyor = Gentle Product Handling!

Zoned Conveyors Prevent Accumulation-Related Damage

Unlike the traditional single-belt conveyor system, Zero Contact Zoned Conveyor lines run multiple individually-managed accumulation zones carrying pallets from workstation to workstation.

If one of the zoned pallets hits a stop, the system can automatically turn off the zones upstream one by one, preventing subsequent pallets from banging into each other.

With one pallet per zone, and a minimum 2'' gap between products, the risk of product damage is significantly reduced. Without the risk of accumulation, products move more gently down the assembly line.

Why Traditional Conveyors Can Cause Product Damage

Traditional conveyors consist of a single belt that moves the pallets. If a pallet hits a stop on the conveyor line, the pallets behind it start to accumulate.

This accumulation causes backpressure. The greater the accumulation of stuck pallets, the greater the accumulated force when a subsequent pallet hits the stop. This can create hundreds of pounds of force, leading to product damage. But with the use of zoned conveyors, with the Zero Contact Zoned Conveyor this risk can be avoided!

Dedicated DC Motors Means Conveyors Only Run As Needed

With traditional conveyors, there is a single AC motor powering the belt. Whether or not the product needs to move, the belt will keep on moving forward.

The Zero Contact Zoned Conveyor’s individual zones are powered by their own dedicated DC pancake motor. This means the product's ANC conveyor only moves when it needs to move.

If there is any issue on the conveyor line, zones can be stopped individually. This improves product handling, and ensures subsequent product is handled with the utmost of care.

Glide-Line's Zero Contact Zoned Conveyor = A Customizable, Cost-Effective Gentle Product Handling Solution!

Zero Contact Zoned Conveyors tackle the biggest challenges when gentle product handling is needed:

With traditional single-belt conveyors, a stop on the line causes pallets to accumulate. This can cause product damage when subsequent pallets hit the stop with greater and greater force.

With traditional single-belt conveyors, a stop on the line causes pallets to accumulate. This can cause product damage when subsequent pallets hit the stop with greater and greater force.

- Unlike traditional conveyor systems, Zero Contact Zoned Conveyors don’t use a single belt. Instead, we use separate “zones” to prevent pallets from touching each other. Zero contact means zero product damage!

- With each “zone” powered by its own motor, zones can be stopped individually if an issue occurs on the conveyor line.

Add in Glide-Line’s ability to configure customized solutions in half the time of competitors, and you have yourself a strong alternative to traditional conveyors!

Ready to get started? Contact us now to see if Glide-Line’s Zero Contact Zoned Conveyors can help you build a cost-efficient system!

Leave a Comment