The Zero Contact Zoned Conveyer is very popular amongst Glide-Line products. The Zero Contact Zoned Conveyer solution is a go-to for our application engineers, because of the enabling technology. It is also something that a lot of other companies don't offer.

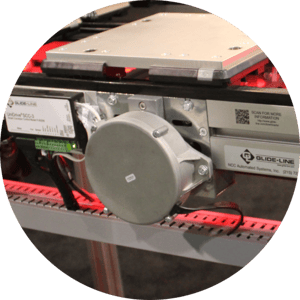

It’s small modules of conveyor units, so basically it’s one little zone of DC conveyor per product or pallet. If we have any product that can be carefully moved without being jostled, a DC-zoned conveyor is the perfect approach. It's set up with sensor brackets, and with stops that will modulate individually at its singularity along the line.

The Zero Contact Zoned Conveyer really gets its popularity from the ability to index your products or pallets in the individual zones or conveyor segments. It gives you full control of the pallets. It lets you know where they are at all times. This solution allows you to seamlessly handle pallets or products directly without bumping into each other. It also provides smooth and elegant motion from zone to zone. It relieves the need to accumulate pallets or products against one another, to keep products from jostling and bumping into one another.

The zoned approach allows you to de-accelerate certain segments at a time while others might be idle or moving at a different speed. It allows it to move very, very elegantly through the assembly line so we have found it very useful particularly when there is a whole series of operators still doing manual processes, it works really well.

Oftentimes it's desirable to introduce short sections of DC-driven conveyors as opposed to longer sections of AC-driven conveyors. In doing so you are only running small little motors on short segments, rather than running these big long lengths of conveyors when you don't need to. You’re saving a lot of energy consumption in your building. We took a liking to this solution and made it popular ourselves and through many successful projects. It's a great way to solve a lot of problems.

Oftentimes it's desirable to introduce short sections of DC-driven conveyors as opposed to longer sections of AC-driven conveyors. In doing so you are only running small little motors on short segments, rather than running these big long lengths of conveyors when you don't need to. You’re saving a lot of energy consumption in your building. We took a liking to this solution and made it popular ourselves and through many successful projects. It's a great way to solve a lot of problems.

Leave a Comment