- Why Glide-Line

- Hardware Systems

- Conveyor Solutions

- Glide-Line Devices & Accessories

- Glide-Line's Zero Contact Zoned Conveyor

- Glide-Line 360 Unlimited Solutions

- Customized Solutions Gallery

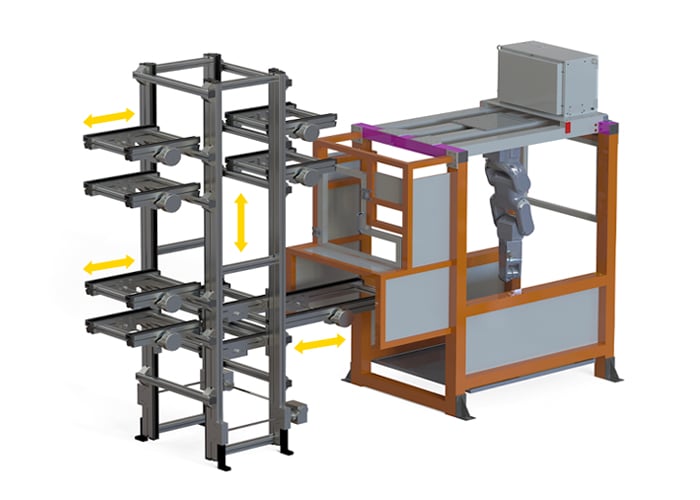

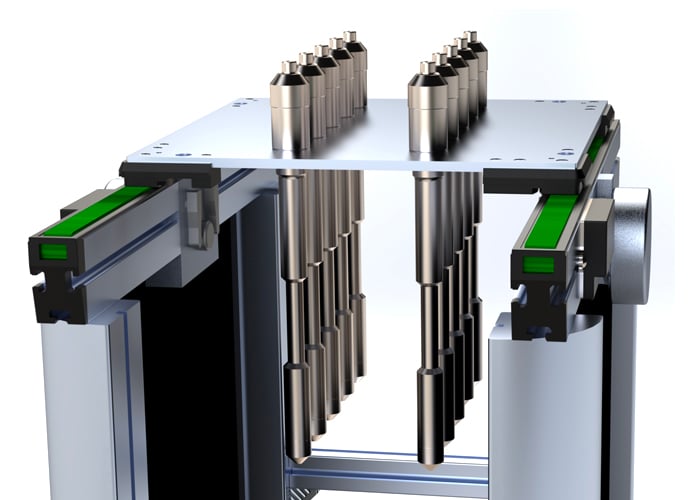

- VTU Solutions

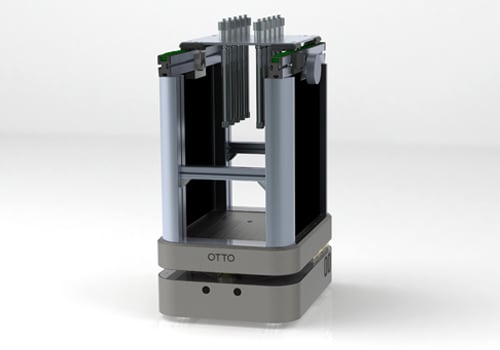

- Conveyors for AMRs

- Software Solutions

- About

- Resources

- Blog

- Videos

- Contact