Automatic guided vehicles, or AGVs, are changing. With new, faster, more efficient technology options, no longer do these robotic vehicles need markers or visual guides on the floor to function. Their new iterations, known as autonomous mobile robots, or AMRs, are instead programmed to move within your clients’ processes with incredible flexibility, using powerful software to manage their moves.

In addition to more efficient software, your clients frequently ask for more efficient, multi-use AMRs to simplify their process, while bringing a higher ROI for the robotic vehicles. High flexibility is no longer optional; it’s a standard that must be met. Adding conveyor toppers to your clients’ AMRs can improve the flexibility and functionality of the vehicles. Choosing a provider of those conveyor toppers doesn’t need to be complicated. Here are three reasons integrators choose Glide-Line when they’re looking for lightweight, yet powerful AMR conveyor toppers.

DC drives are standard

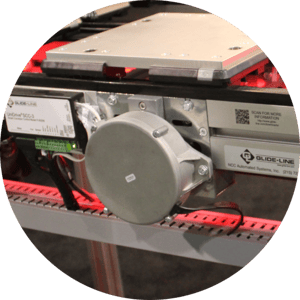

Glide-Line is flexibility, so we are a natural fit when you’re looking for added flexibility for your clients’ AMR conveyor toppers. DC drives are an option as a standard for all Glide-Line’s conveyor toppers and individual strands, including those for AMRs. We don’t need to specially modify our conveyor toppers for use on a DC drive because we’re already built to do so, and the DC drives are incredibly compact to maximize efficient space use. The best part? This doesn’t add financial cost or additional lead time to your integration.

Powerful motion in a compact space

Glide-Line’s DC-driven conveyor toppers are like ants: their capacity and strength are far greater than their compact size indicates. Our conveyor toppers can be modified to any size needed for the AMRs you’re working with, down to the millimeter. And, it’s an incredibly powerful conveyor, to boot. Phenomenal power in an itty-bitty space - the best of both worlds when it comes to AMR conveyor attachments.

Lightweight conveyors use less battery

Lightweight conveyors use less battery

The number 1 reason our integrator customers choose us is because we give integrators and their clients the lightest conveyor possible, with the highest power. We don’t need to modify our designs to improve capacity and be lighter-weight; we’re already building to accommodate these needs as part of our standard line. Read more about this in our post about the design features that are standard in our lightweight AMR conveyor toppers, which can handle small-to-medium payloads.

For your clients who need a lightweight AMR conveyor topper for transporting products under 200 pounds, consider a manufacturer like Glide-Line, whose conveyors are configurable to be lightweight and DC-driven immediately and without any modifications necessary. Learn more about our AMR conveyor topper options in our ebook, How Autonomous Mobile Robot (AMR) Integrators Incorporate A Lightweight, Customizable Conveyor To Adapt To Their Application and Product.

Leave a Comment