When you’re searching for an efficient way to create conveyor system layouts for your customers, Glide-Line has some fantastic “standard custom” solutions for you. Our Customized Standards are standard conveyors configured or even customized to be essentially custom-built for your customer’s process. One such option is to reduce the number of drives, saving costs for equipment and cibtirks, and slave drive power transmitted through our steel tensioned timing belts.

About the Slave Drive Conveyor Solution

With fewer drives and with cost savings for both controls and mechanical equipment, the Slave Driven Conveyor Solution from Glide-Line is a hit for integrator customers - particularly for controls engineers.This solution can be customized with other conveyors and units as well. Below, we dive into how this solution can be applied in a real-world example.

With fewer drives and with cost savings for both controls and mechanical equipment, the Slave Driven Conveyor Solution from Glide-Line is a hit for integrator customers - particularly for controls engineers.This solution can be customized with other conveyors and units as well. Below, we dive into how this solution can be applied in a real-world example.

A Guide to the Slave Drive Conveyor Solution

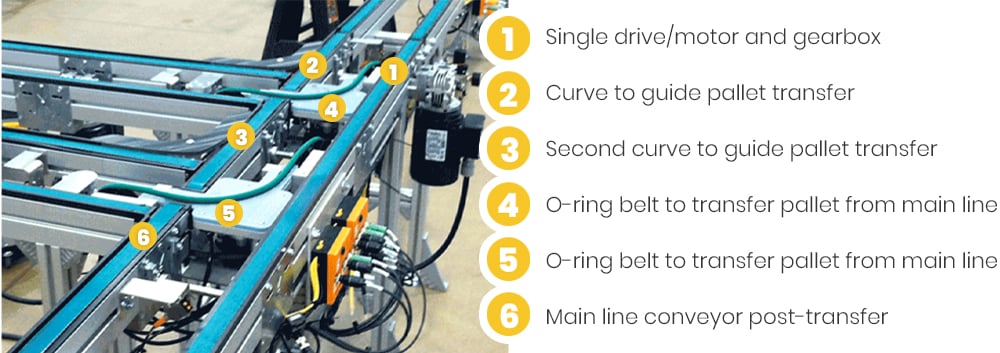

Take a look at how we apply this solution, running those four conveyors and two curves using one drive and two slave modules to assist. You can also see the o-ring belts that assist with transferring the pallet from the main trunk line to the transverse twin strand conveyors, also run using the single motor.

This solution works for products up to 50 pounds; with more weight, you’d need to add additional drives to support the weight properly. In this example:

- A single drive that controls the functions on one to two curves, two pop-up merge o-ring belt conveyors and two twin strand conveyors

- A single drive controlling functions with a different kind of transverse conveyor(s) at any angle from the main trunk line

- Lift Transfer Units that lift and engage the pallet to a new conveyor, perpendicular to the direction of flow

This particular solution not only reduces the number of drives and gearboxes needed, it also reduces the size of the control panel since you don’t need as many VFDs or starters in the panel. This means less time panel wiring, field wiring, and programming, as well. Control engineers in particular are a big fan of these efficiencies.

When to use the Slave Drive Conveyor Solution

This solution can be used by any process that includes curves, corners, Lift Transfer Units, or loop systems. Each of these types of systems can benefit from the addition - or rather, reduction - that is the Slave Driven Conveyor Solution.

Maximizing the power of a single drive is just the start of the innovations Glide-Line provides in unique solutions for applications engineers. For more information, contact us to see where this efficient, cost-saving solution can be applied in your next project.

Leave a Comment