Our Vertical Transport Units are some of our most unique innovations that we offer. Departing from the typical pneumatic lifts between only two heights, we’ve developed an entire line of VTUs that use electrically-driven actuators to control the height. We can program for multiple stops throughout the vertical shaft to achieve previously unthought-of efficiency in a single VTU. Here are 4 reasons our clients and their customers choose our VTUs over competitors’.

Smooth motion control

Smooth motion control

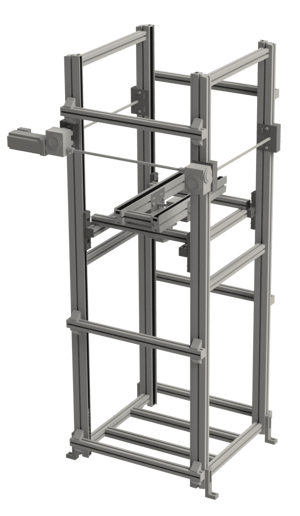

The deck of our Vertical Transport Unit is a simple conveyor. This belt-driven deck conveyor can be configured to any width or length to accommodate products, boxes, or totes. The need for pneumatic actuators is eliminated because the deck is lifted using an electrically-driven belt-driven vertical conveyor in most instances (we do offer a pneumatic option for those that want it, but it is rarely selected). Electrically-driven lifts help ensure smooth motion and transfers from one height to another.

The deck of our Vertical Transport Unit is a simple conveyor. This belt-driven deck conveyor can be configured to any width or length to accommodate products, boxes, or totes. The need for pneumatic actuators is eliminated because the deck is lifted using an electrically-driven belt-driven vertical conveyor in most instances (we do offer a pneumatic option for those that want it, but it is rarely selected). Electrically-driven lifts help ensure smooth motion and transfers from one height to another.

Stop position flexibility

Stop position flexibility

Our VTUs are controlled using programmable movement, either using a step- or servo-driven motor. Many customers use a backup proximity sensor to verify where each stop position is, when to slow the deck down, and where the “home” position is. This, combined with the precision and position knowledge from the servo or stepper allows us to have a VTU with multiple optional stops in a single footprint.

Multiple options for configurations

Multiple options for configurations

Our VTUs are incredibly configurable. They can carry up to 500 pounds at one time. They can include multiple decks, both moving distinctly at one time, with varying stops throughout the height of the VTU.

Additionally, any of our conveyors can be made into the “deck” of the VTU. Each deck has its own motor, so each one can be uniquely programmed to discharge or intake products, boxes, or totes in the single VTU footprint.

Download our guide, Innovative Ways to Create Customized Lifts and Vertical Conveyors, for even more examples of configurations you can make for your customers’ VTUs.

BYO servo motor

BYO servo motor

For those customers who want to provide their own servo motors to control the vertical movement of the VTU, we are happy to support them. We can provide the mechanical portion, and our engineering team works with the customer's data to help them size their own servo for the application so they can utilize their preferred servo motors and drives to fit the Glide-Line equipment.

In summary, we can provide a VTU with a Glide-Line-provided stepper, VTU with your customer’s servo or stepper, or we provide the servo and the controls. Read our motor guide for more details.

VTU in Action

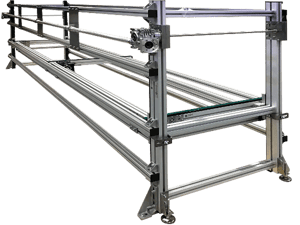

Recently, we assisted a customer, an Aerospace Industry Integrator, with a unique challenge by developing a specialized VTU for them. We configured a conveyor system with our Vertical Transport Units (VTUs) to act as the elevator between an upper and a lower conveyor section. This VTU was designed to support and maneuver for a 12-foot-long pallet!

Recently, we assisted a customer, an Aerospace Industry Integrator, with a unique challenge by developing a specialized VTU for them. We configured a conveyor system with our Vertical Transport Units (VTUs) to act as the elevator between an upper and a lower conveyor section. This VTU was designed to support and maneuver for a 12-foot-long pallet!

In this particularly challenging situation we came across, we adapted our VTU to act as a 90-degree Lift and Transfer at the same time. By rotating the deck conveyor of the VTU 90 degrees, this VTU can also function as a transfer by lifting the product up, off the main line, and conveying it onto a perpendicular spur line for station work.

For more information on this unique case, read our case study.

Clients and their customers choose to work with us for a number of reasons, but they love our VTU products in particular because of their configurability and our willingness to problem-solve along with them. We hope you’ll contact us with your next challenge and see how we can help you with a solution!

Leave a Comment