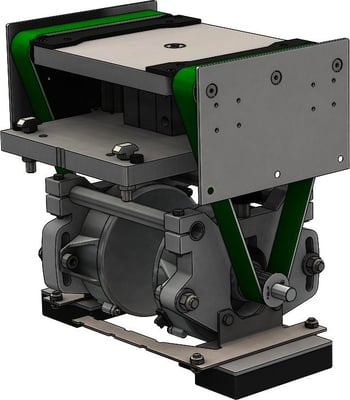

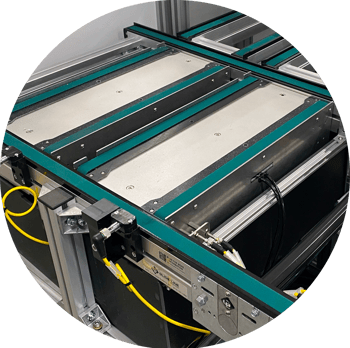

What is a Lift and Transfer Unit? Simply put, the Lift Transfer Unit picks the product up off the conveyor by 8 mm to clear the pallet guide and to complete a right angle transfer from one conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two-, three-, and four-way traffic control conditions.

What is a Lift and Transfer Unit? Simply put, the Lift Transfer Unit picks the product up off the conveyor by 8 mm to clear the pallet guide and to complete a right angle transfer from one conveyor to another. Each unit contains a pair of belts that lift to engage the pallet perpendicular to the direction of flow. The lift action raises the pallet up and over the guide rail so it can be conveyed onto the adjacent transport conveyor. Units are bi-directional and can be set up to manage two-, three-, and four-way traffic control conditions.

Built to your specifications, our highly configurable Lift Transfer Units are customizable to your client’s process, is available at any size in 1mm increments, and has options for drives (including a 24 volt DC option). It’s streamlined using the latest technology.

So, hit the turn signal, cause your pallet can now change lanes!

Check out this video to see it in action…

We build the Lift Transfer Unit to the client’s specifications to meet their exact design criteria, but depending on the layout and the customer’s needs, we’ve also offered customization on the top plate. For example, we have altered pallet top plates so they could be ported or modified to be used as a workstation and a transfer and not just a standard stand-alone transfer.

We’re able to locate the pallets accurately within five thousandths of an inch, allowing the pallet and the LTU to assist in automation operations.

The conveyor belt itself is also configurable. We use T5 timing-style conveyor belts for positive drive. We have several belt materials available to service a wide range of pallet handling conditions, including antistatic materials available suitable for operation in static-sensitive areas or with static sensitive payloads. The conveyor utilizes all ball-bearing-supported rolling elements for long, maintenance-free operation.

Love specs? Well, check out the Lift and Transfer Unit’s features, specs and options:

Features:

- T5 timing style conveyor belts for positive drive

- Several belt materials available to service a wide range of pallet handling conditions

- Utilizes all ball bearing supported rolling elements for long maintenance free operation

- Antistatic materials available to suit operation in static sensitive areas or with static sensitive payloads

- Highly configurable

- Bolt-up compatibility with other leading brands

Specifications:

Specifications:

- Speed Range – 3.5 to 70 m/min

- Bi-directional operation

- Payload Capacity – 150 Lbs. @ 80 psi

- Pallet length range – 160mm to 1040mm in 1mm increments

- Pallet width range – 160mm to 1040mm in1mm increments

- Belt Type – 25mm wide polyurethane core T5 timing belt with steel tension members

- 40mm bore lift cylinder

- 10mm lift stroke – 2mm below conveying surface to 8mm above conveying surface

- G1/8 ports

Options:

- Various bolt-on dampened stops available

- 110-480 VAC drive packages available in 1 and 3 phase

- Guard package

- 24vdc enclosed drive system

- Additional DC drive options including control cards

Leave a Comment