Rotating products smoothly and gently in your automation system can be challenging. Inefficient throughput, prohibitive costs, and overly complicated customizations are just a few of the problems integrators face when asked to include product rotation in their designs. Others include:

-

Abrupt motions while rotating products on traditional conveyor solutions (this is the number one complaint!)

-

Transporting large, unwieldy products or pallets around a curve

-

Maintaining or changing product orientation easily

-

Minimizing product damage resulting from pallet stops

-

Controlling extra spending on ancillary equipment needed for inspecting and/or lifting and rotating products

-

Rotating products directly in an automated conveyor line

Read our ebook to find out more about each of these challenges and how Lift and Rotate Units from Glide-Line can help solve them.

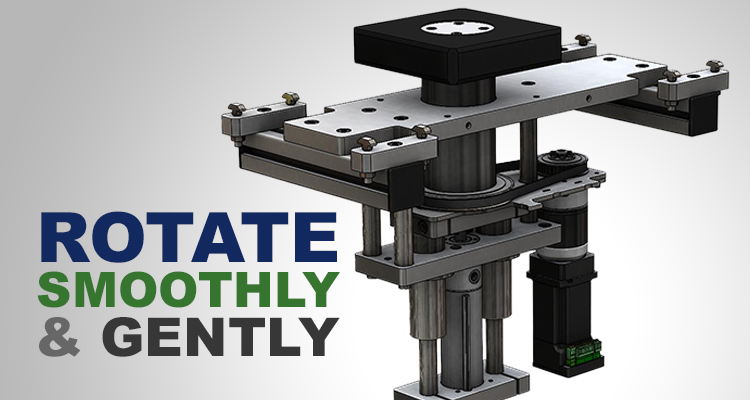

Our Lift and Rotate Unit creatively solves three overarching challenges we hear from our integrator clients.

1. Motion Control

The Glide-Line LRU is step-servo-driven. Acceleration and deceleration are smooth, controlled motions.

2. Location Repeatability

The Glide-Line LRU comes up under the pallet, lifts it up off the conveyors, and rotates it as needed. Due to the servo-driven rotation, It’s very accurate when it turns to exactly where it’s programmed to rotate and back to its original position. This makes the rotation reliable and repeatable.

Pins can be added to the device (designed to fit in pre-drilled pallet holes) to improve accuracy further.

3. Multi-Angle, Multi-Stop Custom Programmability

The Lift and Rotate Unit can have different rotation degrees for each new pallet if it’s programmed to do so – that’s how much control your client has over the rotation of pallets.

Our competitors’ rotation devices have only two rotation locations max, and they have limits on how far the pallet can rotate. Ours, on the other hand, can rotate a product to any direction at any angle. The Lift and Rotate Unit (LRU) is designed to turn pallets or sheet goods between 90 and 180 degrees in a clockwise or counterclockwise direction and can stop as many times as needed at any angle in between.

The Lift & Rotate in Action

The Lift and Rotate Unit has the ability to problem solve for a variety of different applications:

-

360 degree part inspection in the automation system

-

Change the orientation of a part or pallet as it travels downstream on the conveyor line

-

Serve as a pass-through device, lifting the pallet onto a overhead platform to be worked on, then retracting to allow for downstream production to continue (vertical bypass)

If you’re facing challenges with product or panel rotation, there is a better way to rotate pallets in your automation systems. Modular conveyors with Lift and Rotate Units able to rotate products in-line are a simple, efficient, and creative way to overcome your challenges. The LRU’s versatility, function, and compatibility make it a go-to for many of our integrators once they start incorporating it into their designs.

Leave a Comment