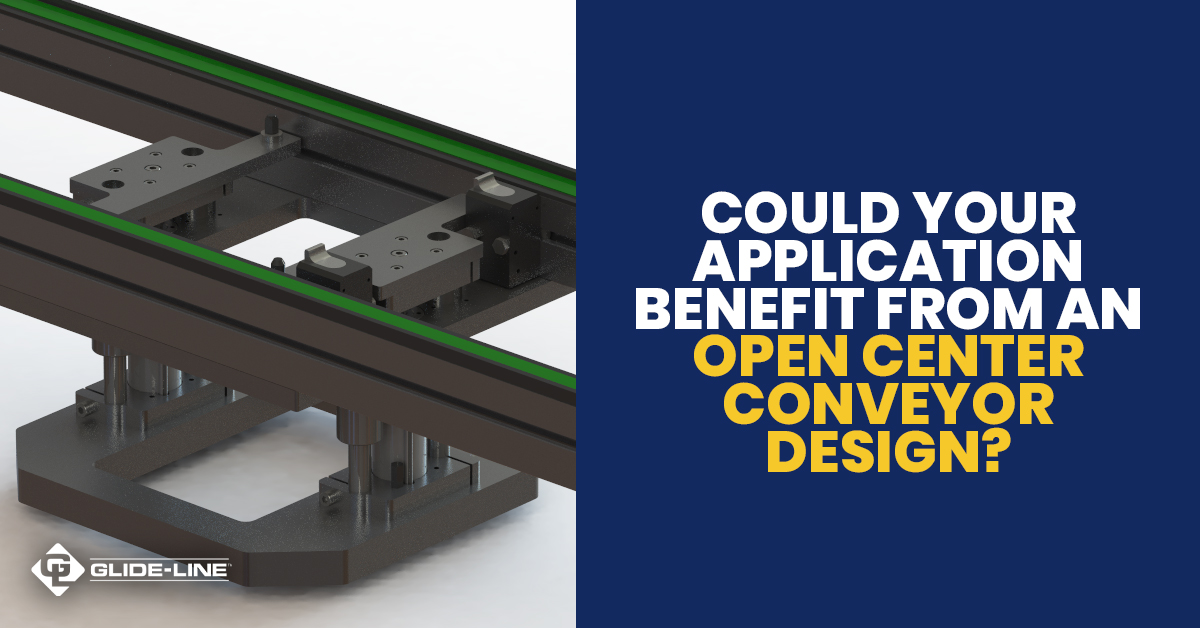

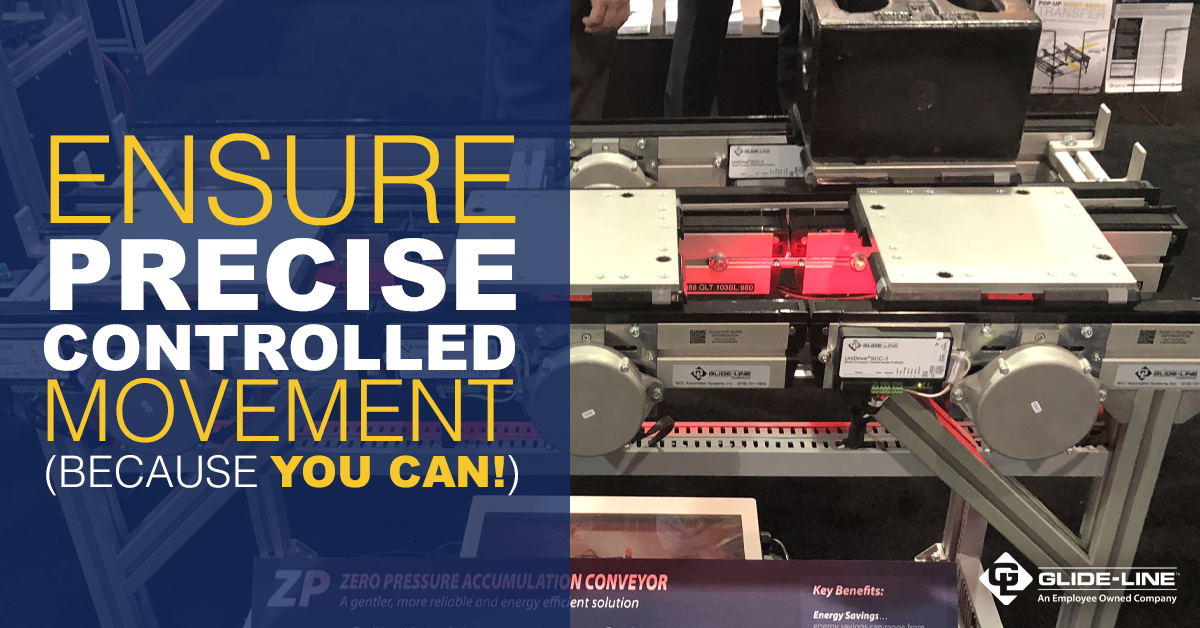

The Lift & Locate: the go-to solution for locating during assembly. But what happens when your customer’s process is a little outside the norm? Whether it’s a unique product, process, position, or proportion, Glide-Line’s custom solutions are always available. We provide a number of Lift & Locate conveyor units out of the box, but can customize any of them to your customers’ specifications: product weight and/or size restrictions, space limitations, or nearly anything specific to your customers’ applications. The best part? We can even give you the tools to customize the engineering designs yourself. But we’ll get to that later! First, some examples:

Read More