Indexing electronic components between assembly stages can become a challenge when there is high friction on the belt, when accumulation is involved. The heat generated by friction can damage the belt, leading to higher maintenance costs and excessive downtimes.

You also have to consider product damage when accumulating or indexing assemblies. If you can control every item within each zone, you can prevent parts from jarring or moving around within fixtures. Components like batteries, PC boards, sensors, or transformers are sensitive to bumps and knocks. A conveying solution that gives you exact control over acceleration, deceleration, and travel speed helps ensure you limit product damage, reduce wear and tear, and maximize your throughput during every shift.

You also have to consider product damage when accumulating or indexing assemblies. If you can control every item within each zone, you can prevent parts from jarring or moving around within fixtures. Components like batteries, PC boards, sensors, or transformers are sensitive to bumps and knocks. A conveying solution that gives you exact control over acceleration, deceleration, and travel speed helps ensure you limit product damage, reduce wear and tear, and maximize your throughput during every shift.

Here’s how Glide-Line’s Zero Contact Zoned Conveyor can help.

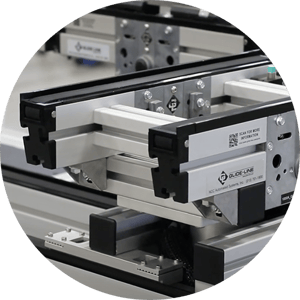

A Zero Contact Zoned Conveyor for Precise Indexing Control

Electronic components require specialized product handling solutions. Controlling the flow of products through different assembly stages starts with a Zero Contact Zoned Conveyor. This design ensures no products come into contact on the line and provide gentle product handling with zero back pressure.

Run-on-demand control gives you:

- Elegant product protection with a minimum gap of 2” between items

- Better Overall Equipment Effectiveness with zero product-to-belt friction

- Improved energy efficiency by only starting and stopping the sections when required

Glide-Line can even provide Zero Contact Zoned Conveyors for clean-room environments, white polyurethane belts deliver greater protection. The systems are configurable according to your application requirements and you can start designing your ideal layout today with our IMPACT! software.

Design a Zero Friction Indexing Conveyor for Electronic Components

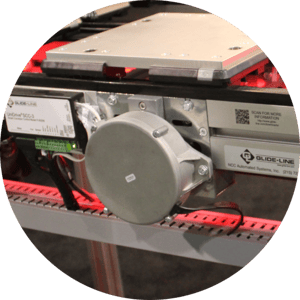

By having an individual controller for each zone, you can communicate between sections to ensure uniform control of motion during indexing. Flexible and modular design elements mean you can adjust the system to solve any unique challenges inside your facility.

Additional solutions like pallet shuttles, merge and transfer stations, as well as our 360 completely customizable product line gives you maximum freedom for electronic component product handling.

Additional solutions like pallet shuttles, merge and transfer stations, as well as our 360 completely customizable product line gives you maximum freedom for electronic component product handling.

Pallet buffers, lift and transfer shuttle, vertical transfer units (VTUs), and drop and rotate transfers (DARTs) let you manipulate products in any way you want around the plant. You can design the system to accommodate manual operations, automated transfers, or change the orientation and angles for visual inspection.

Combining a base system like our timing belt with our range of standard custom solutions lets engineers redefine what they can accomplish with our conveyors.

How to Choose the Right Zero Contact Zoned Indexing Conveyor for Your Application

At Glide-Line, we understand that application requirements vary greatly between manufacturers, component types, and industry requirements. Medical devices require the highest levels of sanitation while electrical components may have to undergo testing before leaving the line. By creating a modular design, you can accommodate any of your process stages and automate most of your material handling requirements.

The key differentiator is our willingness to work with customers to find a solution that fits. We can configure systems with different drive types (AC, DC, and servo), different conveying mediums, and electronic or pneumatic actuators. Because we are always looking for new ways to optimize our designs, our customers get the best lead times in the industry and we have the spare components available to keep your facility running productively.

Rethink Your Indexing Conveyor Design with Glide-Line

When you have to guarantee product quality for every production run, a zero backpressure, indexing conveyor will quickly become your best friend at work. You can expertly move products between process stages, transfer items elegantly to bypass lines, and automate your storage and stacking operations while preventing any damage with damped stops and starts throughout the line.

Glide-Line’s zero contact zoned indexing conveyors give you the design freedom you want while eliminating product damage. Reach out here to find out more.

Leave a Comment