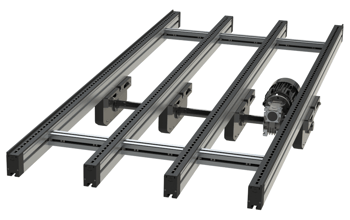

Glide-Line’s completely configurable roller chain conveyor is the first of its kind, offering precise and dynamic control over the physics of the pallet carrying rollers.

Glide-Line announced the release of their completely configurable steel roller chain conveyor system featuring dynamic traction control with a built-in accelerator to assist with faster start-up. A first of its kind, this product allows mixing and matching of traction control in a line, from low back pressure to high traction, with ultimate configurability and flexibility within.

Glide-Line, a leader in the assembly automation industry, provides versatile solutions allowing customers the flexibility of configuration. Glide-Line’s advanced configuration tools enhance the design experience for customers, giving them 100% creative freedom to customize the Glide-Line product how they want it and to their specific needs. Glide-Line’s digital manufacturing process offers custom configuration to be built quickly, efficiently, and fast, meeting tight project deadlines.

Glide-Line, a leader in the assembly automation industry, provides versatile solutions allowing customers the flexibility of configuration. Glide-Line’s advanced configuration tools enhance the design experience for customers, giving them 100% creative freedom to customize the Glide-Line product how they want it and to their specific needs. Glide-Line’s digital manufacturing process offers custom configuration to be built quickly, efficiently, and fast, meeting tight project deadlines.

“I’m excited to announce the launch of our new roller chain conveyor with dynamic traction control. Our new roller chain conveyor isn’t like any you’ve worked with before. With an innovative twist on a long-run traditional conveyor, we can now offer customers the configurability, flexibility and quick lead times they’ve come to expect with the strength and heavy duty build of a roller chain conveyor. For customers ready to add configurability to their steel roller chain conveyor projects, we now offer an innovative solution.”

Kevin Mauger, President of Glide-Line

Heavy Duty Construction with Added Flexibility

With hardened steel carry rails—instead of industry standard plastic—and Glide-Line’s signature innovative edge, this completely configurable roller chain conveyor gives precise and dynamic control over the physics of the pallet carrying rollers. This ability to control traction results in much faster acceleration speeds from stop locations with a built-in actuating accelerator and customizable positioning that even allows for field repositioning. Precise control means you choose when the accelerator is on and when it’s off, and where it is located. The adjustable position underslung drive(s) require no breaks in the CV extrusion offering continuous beam integrity.

With hardened steel carry rails—instead of industry standard plastic—and Glide-Line’s signature innovative edge, this completely configurable roller chain conveyor gives precise and dynamic control over the physics of the pallet carrying rollers. This ability to control traction results in much faster acceleration speeds from stop locations with a built-in actuating accelerator and customizable positioning that even allows for field repositioning. Precise control means you choose when the accelerator is on and when it’s off, and where it is located. The adjustable position underslung drive(s) require no breaks in the CV extrusion offering continuous beam integrity.

With flexible placement in design, dynamic acceleration sections create instant traction and can be turned off or on via air. A customizable vertical position of the driveshaft accommodates low hanging pallet or payload features. Glide-Line’s roller chain conveyor’s width can be adjusted to accommodate any product or process. It is inherently reversible and comes with optional industry-leading hardware jam prevention guards to reduce catastrophic jams and regular reliability issues.

Glide-Line delivers everything customers need and want in a roller chain conveyor.

Leave a Comment