Inspired by pure frustration with available technologies, Glide-Line embarked on a journey to redefine what’s possible with automated conveying and product handling solutions. Over the last decade, we’ve kept our focus on our core principles. These are:

- To be fast – We had to optimize all facets of the design, quote, and build stages for any solution we develop.

- To be flexible – Our solutions had to solve unique application challenges that traditional conveyors simply can’t handle.

- Be easy to work with – We had to understand the frustrations of our customers and deliver solutions that overcome every pain point they have.

This persistent effort eventually led to a product range that provides extensive modularity, cost, and simplicity benefits to our customers. Today, Glide-Line has the most flexible conveying solutions available and is constantly working to apply our collaborative spirit to new challenges.

One of our recent projects in the life sciences manufacturing industry benefited from our willingness to revisit and rethink what’s possible. Let’s explain.

Quantifying the Value of Collaboration at Glide-Line

A customer had previously submitted a bid on a project for a high-profile medical manufacturing company. As the application required automated product handling, the initial proposal included roller-powered conveyors.

From our own experience, we knew that this design had some limitations when it comes to delicate product handling applications. Some of those include:

- Imperfectly balanced rollers, which leads to vibrations on the conveyor line and uneven traveling

- Product-to-product contact that cause damage and increase the scrap rate but also affect productivity

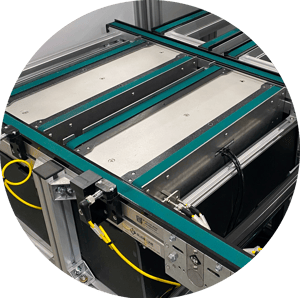

Glide-Line’s product team felt confident that we could supply an adequate solution using our alternative twin string timing belt technology.

Glide-Line’s Conveyors Provide Cost and Schedule Benefits to Customers

By the time we were brought in, the project’s bid had already gone through a series of evaluations at the end-user. Our customer, who is a systems integrator and supplier of end-to-end automation solutions, won the project and tapped us to supply the product handling systems.

By the time we were brought in, the project’s bid had already gone through a series of evaluations at the end-user. Our customer, who is a systems integrator and supplier of end-to-end automation solutions, won the project and tapped us to supply the product handling systems.

Glide-Line decided to assess some of our other solutions against the same application requirements. The results were undeniable.

For any other product-handling manufacturer, making this kind of decision would be a non-starter. However, Glide-Line found that not only could we improve the design, but we could also deliver a more robust, flexible, and cost-effective solution – and more importantly – stay on schedule.

How Glide-Line Went Above and Beyond to Help This Customer Succeed

The modularity and simplicity of our standard timing belt conveyors and vertical transport units enable Glide-Line to configure the length and width of our solutions in small increments. When it comes to specialized product handling applications, this approach makes our design flexible and cost-effective compared to a rigid, traditional roller-powered conveyor system.

The modularity and simplicity of our standard timing belt conveyors and vertical transport units enable Glide-Line to configure the length and width of our solutions in small increments. When it comes to specialized product handling applications, this approach makes our design flexible and cost-effective compared to a rigid, traditional roller-powered conveyor system.

We didn’t just provide a more efficient system, but our multiple-axis, multi-strand conveyors could fit perfectly within the requirements of the original program. The system allows for controlling traffic while eliminating any hard stops that could lead to product damage. Totes, trays, and pallets all travel through the facility on conveyors that elevate, orientate, and transfer items between processing stages.

The demanding application requirements involved in the life sciences industry also made our timing belt solution a better option. The clean design and configurable layout meant we could quickly fit different customized standard conveyor solutions into the overall system to achieve better results than the previous proposal.

Yet, the biggest benefit our system provided was a cost saving over $400k compared to the roller-powered option (half the cost!). Delivering such an optimized design within these time constraints required our engineers to collaborate extensively across different organizations and project teams.

Delivering the Best Solutions That Enable Our Customers to Succeed

This is just one example where Glide-Line remained focused on ensuring our customer got the best result in a complex product handling application. Because our solutions are highly configurable and expandable, we could quickly adjust the design using our in-context IMPACT! configuration software to meet the requirements and deliver a simple, modular, and cost-saving alternative to a roller-powered conveyor system.

This is just one example where Glide-Line remained focused on ensuring our customer got the best result in a complex product handling application. Because our solutions are highly configurable and expandable, we could quickly adjust the design using our in-context IMPACT! configuration software to meet the requirements and deliver a simple, modular, and cost-saving alternative to a roller-powered conveyor system.

If you have a demanding conveying application, consider Glide-Line as your go-to resource for handling totes, trays, pallets, or products throughout your process.

To see what product handling capabilities we have to offer, download our Ultimate Guide on Creating a Flexible Automation Conveyor eBook here.

Leave a Comment