Moving on to the second part of the Design World webinar featuring Glide-Line. Here Kevin and Jenna are focusing on the topic: How Speed & Agility Can Set You Apart. You can read through the webinar transcript or simply watch the video for this portion of the webinar.

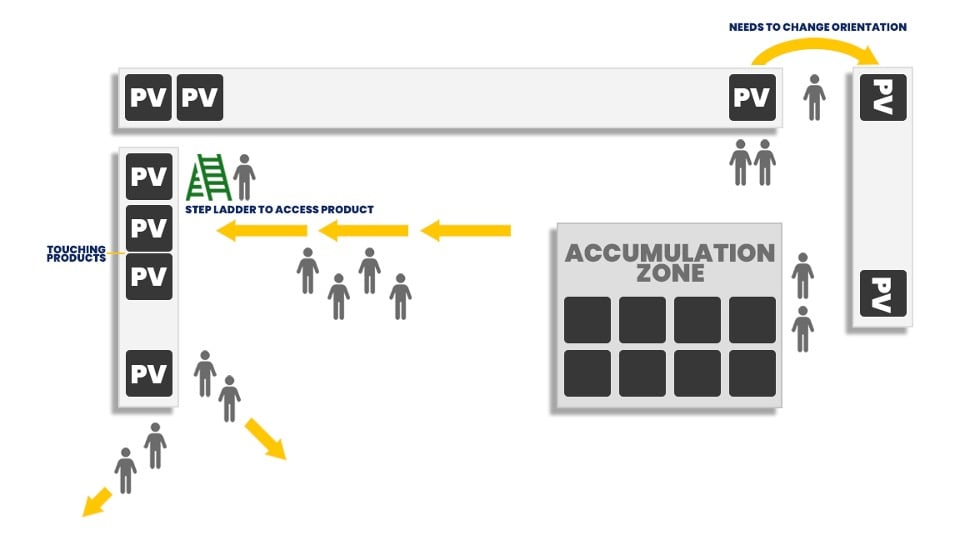

Before we move on to the topic of Speed and Agility, let’s loop back to creating supreme automation flexibility. Here is an assembly line. I want everyone to spend a couple minutes considering these questions & please drop a chat to point out, in an ideal world with no budget, how we can reinvent this line to optimize it, reduce the footprint, add automation & improve cycle time? How can we think differently, leading with flexibility on an assembly line?

- How can cycle time be improved? Where are bottlenecks, where can we think outside the box?

- What parts of the line require manual labor? Which of those locations require someone to lift a part, rotate a part or move a part?

- Can we create a more ergonomic experience to position and move the product more efficiently?

- How can we create better access and exposure while reducing the need to physically touch the product - risking damage

- Where is damage to the product occurring in the line? What can we do differently?

- Where does it seem like there is wasted space - how can we reduce the footprint in an ideal world?

Here are some ways we can improve the line!

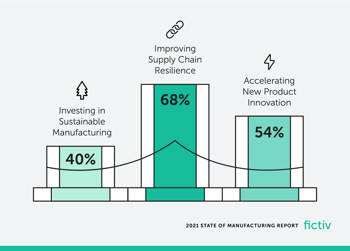

Agility is all about anticipating and adapting to changes in the market landscape. It means being in the right place at the right time with the right offering of products, tools, materials and equipment. It means answering immediate needs of customers and prospects - whether they are manufacturing a drone for your daughter’s Christmas present or are producing the COVID-19 vaccine. A huge part of being agile has to do with our global supply chain. The last few years we’ve seen disruptions causing:

Agility is all about anticipating and adapting to changes in the market landscape. It means being in the right place at the right time with the right offering of products, tools, materials and equipment. It means answering immediate needs of customers and prospects - whether they are manufacturing a drone for your daughter’s Christmas present or are producing the COVID-19 vaccine. A huge part of being agile has to do with our global supply chain. The last few years we’ve seen disruptions causing:

- Unpredictable demand (both high and low) of products and materials testing the reliability of our strategic partnerships, leading many to explore new partnerships ensuring we are working with the right suppliers and reliable manufacturers that can deliver on time.

- Material sourcing - this is a layered issue. Right now sourcing raw materials is a challenge for manufacturers who are getting their materials offshore, because the shipping and transportation industry is experiencing major delays. So at the moment, there is an advantage for those manufacturers with quality, USA-based sourcing methods. But the always true fact about sourcing - regardless of our economic environment - is that it requires a balance between the quality of the raw materials and the affordability - making reliable, consistent suppliers a competitive advantage in manufacturing.

- Amazon effect - the digital landscape we live in has changed shopping patterns, customer expectations and the competitive landscape because it has opened the industry’s reach to other businesses and consumers and it’s access to buy and sell. Consumers now expect quick delivery without compromising on quality or price…. and we're here for it!

All of these disruptions can be seen as a threat or an opportunity. At Glide-Line, we knew our flexibility allowed us to be nimble but to be agile and fast, we knew we had to be able to predict the unexpected so our customers would be prepared to lean on us alway, especially in times of crisis.

All of these disruptions can be seen as a threat or an opportunity. At Glide-Line, we knew our flexibility allowed us to be nimble but to be agile and fast, we knew we had to be able to predict the unexpected so our customers would be prepared to lean on us alway, especially in times of crisis.

We design each solution using in stock parts and materials sourced in the USA, which ensures reliability to our customers. We buy mass volume and then configure to order. We are also vertically integrated which enables streamlined operations by taking ownership over more of the production process. This allows us to provide the best lead times in the industry which also helps our customers who are facing shifting product demand challenges and the ever increasing rush orders / projects.

So a few questions to touch base on where you and your organization stand with some of these trends:

- Are you working with reliable manufacturing partners that deliver on time (Suppliers, Conveyor System Manufacturers)?

- Do you depend on partners who rely on international material sourcing methods?

- Have you experienced extremely high demand the last couple of years?

- What issues came with it and how did your organization address them?

- How did you get through these periods of surge?

- Knowing when and how to scale operations can be a challenge, what questions have you and your organization considered to keep up with growth?

- Are the lines you build operating as efficiently as possible right now?

- Is your equipment being maximized? OEE

- Why can’t your customers increase production any further with the current operation?

- Not enough people to operate the line?

- Material shortage?

- Not enough analytics and data on your current production to drive growth?

- Are you, or your customers experiencing labor shortage? Have you considered additional automation to combat this?

- How have your customer’s expectations changed over the last couple of years? Have you made adjustments to address their wants and needs?

- Have you ever had to pre-order conveyors before the entire design process was done, and then had to design around what you ordered?

- Have you ever had to wait for conveyors to arrive so you could start assembly of your line?

All of these questions come back to being customer-centric. Providing fast, reliable, flexible solutions so our industry as a whole can continue to, as it always has, be the foundation of innovation and opportunity here in the USA.

Leave a Comment