Our semi-customized conveyor systems, also called our “custom standard” solutions, are built to be completely configurable. We offer flexibility, configurable sizing, innovative designs, and short lead times. There aren’t too many “cons” when it comes to working with us for semi-customized conveyor systems, but we hope these comparisons will give you some food for thought as you consider your options for the right manufacturing partner.

PRO: Flexibility

If you’re consistently asking for customizations, flexibility in design, new capabilities, and innovations, a traditional manufacturer may not cut it (at least, not without making you pay an outrageous price for it!). Choose a manufacturer like Glide-Line, who not only accommodates these requests, but plans their entire manufacturing process around them and does so at little to no added cost because our process is built for it

CON: Too many options

Glide-Line’s massive gallery of choices can seem overwhelming without a guide. That’s why all our Sales and Applications Engineers are really teachers and problem-solvers in disguise. We want to help you learn about all the options and guide you to a solution that is flexible in exactly the ways you need it.

PRO: Configurable sizing

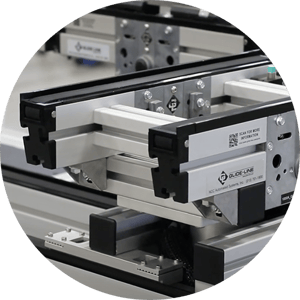

When looking for configurability, be sure that your manufacturer’s definition of “configurable” meets yours. Glide-Line’s conveyors, pallets, and other devices are configurable in 1-millimeter increments, making them extremely versatile to any spacing or product needs.

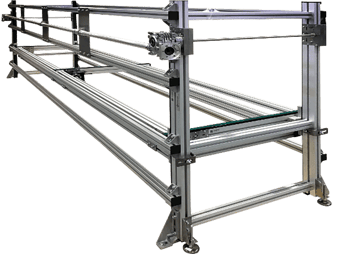

For example, a problematic-sized pallet or tray can easily be accommodated in this situation since both the pallet and the conveyor can be adjusted in length and width to move the product. Check out a recent case study we produced about this where we handled a 12 foot long pallet.

CON: Again, too many options

If you’re used to working with some of our competitors, you may be used to a defined size for pallets, width for conveyors, and limitations for vertical transport units and most other equipment. Fortunately, most of our clients find our lack of prohibitions refreshing - so few find this an actual “con.”

PRO: Innovative designs

When you’re in need of innovative designs, you need a conveyor system manufacturer capable of delivering thought-provoking and unique solutions when necessary. Our blog post, “Unique Assembly Conveyor Layouts and The Best Applications,” gives examples of the most flexible and productive conveyor layouts we’ve designed for some of our clients’ most challenging applications.

We can’t speak for all of the specs you may need, but chances are, no matter what challenge you’re facing or what you’re trying to accomplish with a conveyor, Glide-Line has a solution. We love to be challenged by unique product needs. Here are just a few examples of conveyors we offer as standard, which started as solutions to unique customer needs:

We can’t speak for all of the specs you may need, but chances are, no matter what challenge you’re facing or what you’re trying to accomplish with a conveyor, Glide-Line has a solution. We love to be challenged by unique product needs. Here are just a few examples of conveyors we offer as standard, which started as solutions to unique customer needs:

- 90°/180° transfers: achieved using our Lift and Rotate Unit or our Glide-Line 360 Conveyor (among others)

- Rotating conveyor for transfers: achieved with our Conveyor Rotate Unit

- Access / Manipulate product from the bottom side: achieved with our Open Center Design

- Vertical solutions in small footprints: achieved using our servo or stepper driven VTU solutions (multiple options)

CON: No stagnant conveyors

If you’re looking for old stand-bys and don’t often change the conveyors or systems you recommend, Glide-Line will seem completely out of the ordinary. We don’t offer same-old anything! We’ve improved on many traditional conveyors, from VTUs to steel roller chain conveyors, and we pride ourselves on disrupting the industry. If this change makes you uncomfortable, this could be a “con.”

If you’re looking for old stand-bys and don’t often change the conveyors or systems you recommend, Glide-Line will seem completely out of the ordinary. We don’t offer same-old anything! We’ve improved on many traditional conveyors, from VTUs to steel roller chain conveyors, and we pride ourselves on disrupting the industry. If this change makes you uncomfortable, this could be a “con.”

PRO: Short lead times

Partnering with a versatile conveyor systems manufacturer like Glide-Line will do the most to shorten your lead time. Glide-Line’s engineering and manufacturing process is built for speed; we can ship conveyors in two to three weeks, and devices such as lifts, lift and transfers, lift and locate stations, and more in four to six weeks. This conveyor lead time is cut in half compared to other manufacturers and saves your client significant time and money.

CON: None

We really can’t think of a con for shorter lead times - who doesn’t like lead times half those of competitors? For details, check out our ebook.

Choosing a conveyor system manufacturer is no simple task, particularly when you’re facing a deadline. When you have questions about which equipment might be best for your project, lead time, execution, cost, and support, you may need a resource, not a salesperson.

In our latest ebook, Don’t Buy a Conveyor! (Unless You’ve Taken a Look at this Checklist), we’ve provided a checklist of 26 of our recommended questions. We think these questions will give you the best answers with how to evaluate a best-fit conveyor manufacturer. In our experience, these are the most frequently-asked questions when evaluating a conveyor manufacturing partner - and additionally, we’ve included the most frequently-missed questions as well.

Leave a Comment