Product damage is a common issue with traditional accumulation techniques. With pallets making hard stops, typical methods leave room for improvement (to say the very least!). To prevent products from banging into each other, you need to find alternatives to traditional conveying and accumulation methods! A strong alternative is Glide-Line’ s Zero Contact Zoned Conveyor solution. With Zero Contact Zoned Conveyors, avoid product damage and ensure smooth handling.

Single-Drive Conveyors Can Cause Product Damage. Not with the Zero Contact Zoned Conveyor!

Pallets bumping into each is a common issue with traditional accumulation conveyor designs. Allowing workpiece pallets to contact each other throughout a system can be an issue as subsequent pallets bang into stops and other pallets as a normal course of action. This damage to fragile or partially-assembled products can be a major hidden cost and seriously jeopardize productivity and quality. To prevent accumulation-related product damage, alternative means of conveyance should be considered.

That’s where the Glide-Line's Zero Contact Zoned Conveyor comes into play. Our zoned conveyors eliminate backpressure by adding and maintaining space between pallets all of the time. This minimizes most of the issues that cause product damage.

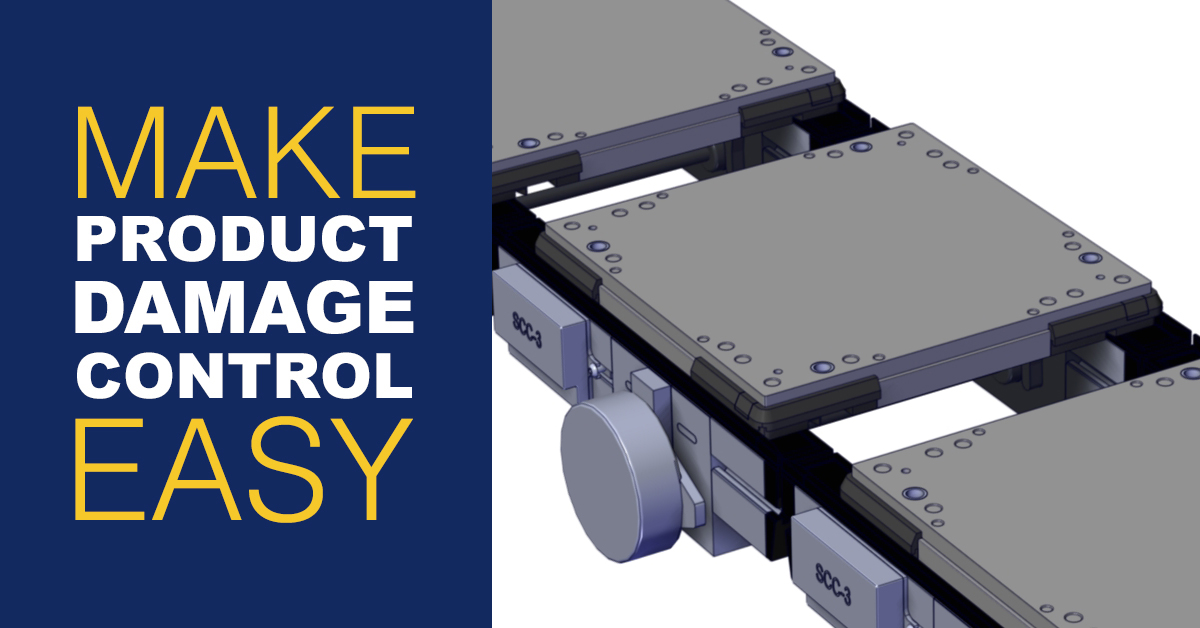

Glide-Line’s Zero Contact Zoned Conveyor solution conquers the issues caused by traditional accumulation conveyors. By arranging Glide-Line conveyors into separate zones with small, independent drives, a permanent gap is created between pallets/products. With Zero Contact Zoned Conveyors, products do not touch each other - no contact, no product damage!

For smooth handling, the Zero Contact Zoned Conveyor does not use “hard stops.” Single-drive conveyors typically use “pop ups” to quickly stop pallets when they enter a production area. While this method can certainly be effective, it gives way to product damage. Upstream pallets bang into the stopped pallet. However, with the Zero Contact Zoned Conveyor, this is not an issue. Conveyor traffic is better managed, with the use of sensors. When a zoned pallet passes the sensor, it automatically turns off. This allows the zoned conveyor to gradually decelerate. The sensor also triggers upstream pallets to stop, preventing them from banging into the stopped pallet.

Zero Contact Zoned Conveyor Logic Controls Make Product Damage Control Even Easier

Most users use their PLC controls for their conveyor systems. But the Zero Contact Zoned Conveyor comes with logic controls of its own, which can save a lot of hardware, code development in the PLC, as well as field wiring. Here are a few reasons why our built-in logic in our driver cards can save you money and ensure smooth handling:

- Zero Contact Zoned Conveyor Logic controls are easy to install. The only requirements are a source power to the motors and connecting zone to zone via plug

- There’s no programming required for indexing operations; all you need to do is wire (and sometimes configure via dip switch depending upon the application)

- Zero Contact Zoned Conveyor Motors are a robust solution - there is literally only one moving part

- Cost-Effective Zero Contact Zoned Conveyor Logic eliminates the need for a control panel/centralized control system with dozens of VFDs, code, and of course results in much less field wiring

- Local I/O on the driver cards allow additional manual control to bypass automatic logic

We Can Help You Build the Right Solution

We can customize the Zero Contact Zoned Conveyor line to fit your specific project needs. No matter how large (or how delicate) the product conveyed, we can help you build the best production line conveyor systems. Not only can we build it well, we can build it quick! You can quickly configure a customized solution using our IMPACT! configuration software. Put it all together, Glide-Line is a strong choice for developing a viable alternative to upsizing.

Want to know more about how reducing back-pressure can lead to a cost-saving conveyor system? Check out our complete guide, The Ultimate Guide To Creating A Flexible Automation Conveyor Application Solution.

Leave a Comment