The life of an application engineer is never boring. Along with all the daily challenges that come with keeping the production line running, engineers searching for suitable solutions that can automate assembly operations when manufacturing complex products is just as entertaining as watching Tommy Boy – if you’re into that kind of thing.

The life of an application engineer is never boring. Along with all the daily challenges that come with keeping the production line running, engineers searching for suitable solutions that can automate assembly operations when manufacturing complex products is just as entertaining as watching Tommy Boy – if you’re into that kind of thing.

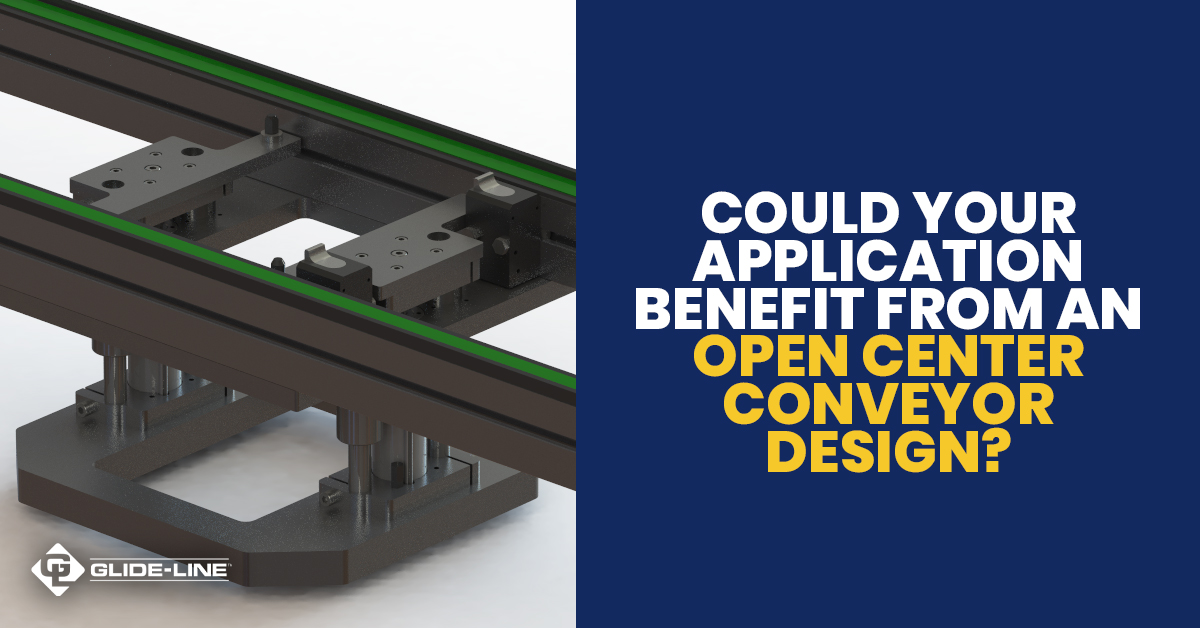

Advances in product design call for innovative conveyor solutions that don’t just give you access to your products but also allow you to transfer items smoothly between stations. With products that have dangling wiring, or medical device applications or even automotive parts, an open center conveyor design allows for the unobstructed flow of items on the line while having the freedom to mount specialty devices to support the manufacturing process.

Below, we’ll discuss some of the innovative open center conveyor designs and solutions available today. An open center conveyor design makes it possible to access your products from either side of the line or efficiently move items that need to hang below the trunk line during the manufacturing process.

Why Assembly Automation is Possible with Open Center Conveyor Designs

Traditional roller conveyors aren’t typically suitable for products with unique geometric designs that need to travel while hanging vertically or have dangling parts (like with medical IV bags) down the line. Even if you could place these items on a pallet and use your roller conveyor, you’ll need to adjust your process equipment to ensure it doesn’t obstruct while moving, transferring, storing, or lifting items.

For these applications, a conveyor with an open center design is an economical solution that enables you to automate your assembly operations efficiently.

Open center conveyors allow you to:

- Design a conveying solution with products hanging vertically between two support structures mounted on the outside

- Automate most of your lift, transfer, and rotate tasks for the optimal presentation without blocking, clogging, or choking products during your assembly application

- Efficiently move products that need to hang below the level of the conveyor and integrate locate, vision, or inspection systems directly on the line

Applications That Can Benefit from an Open Center Conveyor Design

Wherever you need a solution that provides for unobstructed workflow while hanging down below the trunk line during certain build stages, an open center conveyor design can benefit your manufacturing process. A prime example is in applications where you need a cooling cell for parts that are coming out of an oven and require unobstructed airflow from below the conveyor line.

These types of applications include:

- Manufacturing complex electronics that need to go through heating or curing processes

- Battery cell production that needs to hang on the conveyor while moving through automated assembly operations

- Wherever you need to add specialty equipment or devices without having to deal with interference from conveyor components

Using Glide-Line’s Open Center Conveyor Designs to Automate Assembly Applications

Glide-Line provides thousands of configurable conveyor solutions that help you automate any of your conveying, orientation, presentation, and access requirements. Our solutions remain highly customizable and give you the required design freedom to accommodate any special product requirement. With Glide-Line’s solutions, you can design the ideal system to efficiently move, transfer, rotate, or lift items while handling products directly on the line.

You can also get started on designing your ideal open center conveyor solution today using our IMPACT! configurator, which integrates seamlessly with your SolidWorks 3D models. With Glide-Line, you get the fastest lead times in the industry, a host of customized options available, and a dedicated team of application professionals at your disposal to help you design the ideal open center conveying system.

You can also get started on designing your ideal open center conveyor solution today using our IMPACT! configurator, which integrates seamlessly with your SolidWorks 3D models. With Glide-Line, you get the fastest lead times in the industry, a host of customized options available, and a dedicated team of application professionals at your disposal to help you design the ideal open center conveying system.

For more information about Glide-Line’s open center conveyor designs, get in touch with an expert today.

Leave a Comment