- Why Glide-Line

- Hardware Systems

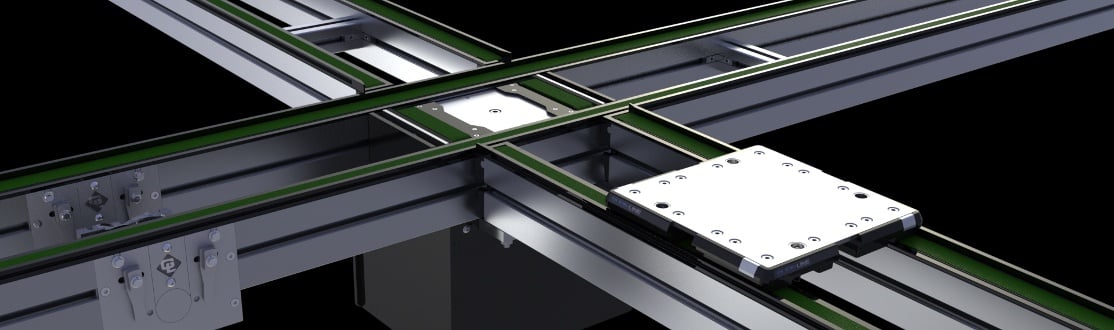

- Conveyor Solutions

- Glide-Line Devices & Accessories

- Glide-Line's Zero Contact Zoned Conveyor

- Glide-Line 360 Unlimited Solutions

- Customized Solutions Gallery

- VTU Solutions

- Conveyors for AMRs

- Software Solutions

- About

- Resources

- Blog

- Videos

- Contact

%20(1).png?width=417&name=Direct%20product%20handling%20zero%20pressure%20(appliance%20project)%20(1).png)