With traditional accumulation conveyor design, precision controlled movement is not normally part of the design requirement or operating principle. This may be fine, or it may be an issue - especially to partially complete products.

Say you have a product where pieces have been put into place but are not yet fastened. The product is moving from one station to another. Rough handling can be detrimental. One hard stop on the line, and BAM!, damaged products and reduced yield.

So what’s the solution? Are there alternatives to the traditional accumulation design? When choosing the right conveyor solution, there is another option. Glide-Line’s Zero Contact Zoned Conveyor solution. With the Zero Contact Zoned Conveyor solution, products can move from workstation to workstation with minimal risk of product damage.

How Glide-Line's Zero Contact Zoned Conveyor Ensure Precise, Controlled Movement

The Zero Contact Zoned Conveyors offer a more elegant station-to-station transport solution for your assembly process. With traditional single-belt conveyors, hard stops are used. This is why products can BANG! right into a stop. Pneumatic stops get the job done, but the lack of finesse can be devastating.

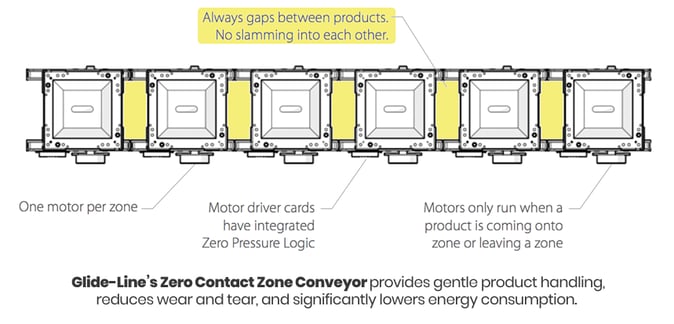

With the Zero Contact Zoned Conveyor solution, we have taken product damage out of the equation. This is because the Zero Contact Zoned Conveyor does not use a single belt. Instead, our conveyors are made up of separate zones. Each zone moves an individual product or pallet down the assembly line.

But where does precision and controlled movement come into play? With the Zero Contact Zoned Conveyor’s alternative to hard stops. Instead of “pop up” stops, our solution uses sensors to direct a conveyor to start and stop. Instead of a single AC motor powering a single belt, each zone is powered by a dedicated DC motor. This means the Zero Contact Zoned Conveyor runs only as needed, ensuring greater control, and significant power savings on the line.

Let’s say a pallet is moving from one assembly station to another. Once it reaches its destination, a trigger tells the conveyor’s dedicated DC motor to turn off. This occurs prior to reaching the zone. Shutting down power ahead of time allows the zoned conveyor to smoothly decelerate into the destination. Subsequently, upstream pallets are also directed to “turn off”. This prevents the pallets from banging into each other, the leading cause of conveyor product damage.

The performance of the Zero Contact Zoned Conveyor is enhanced by its own set of logic controls. End users may prefer to use their own PLC controls, but there are many advantages to using the built-in Zero Contact Zoned Conveyor option. The Zero Contact Zoned Conveyor Logic controls are easy to install, require no programming, and offer the option of additional zone specific control via a local I/O.

Glide-Line Can Help You Build The Right Conveyor Solution

Whether you want to configure a solution, or want us to design it for you, we can help you meet your project-specific needs. Our experience building complex solutions for integrators means we can help you build the best production line conveyor systems.

If you know what you need, and want to build it quick, no problem! With our IMPACT! configuration software, you can configure exactly what you need. Not only that, we can deliver a finished product with half the lead times of our competitors. With all of this is mind, Glide-Line’s Zero Contact Zoned Conveyor solution may be just the ticket to build a system with controlled movement.

Want to know more about how reducing backpressure can lead to a cost-saving conveyor system?

Leave a Comment