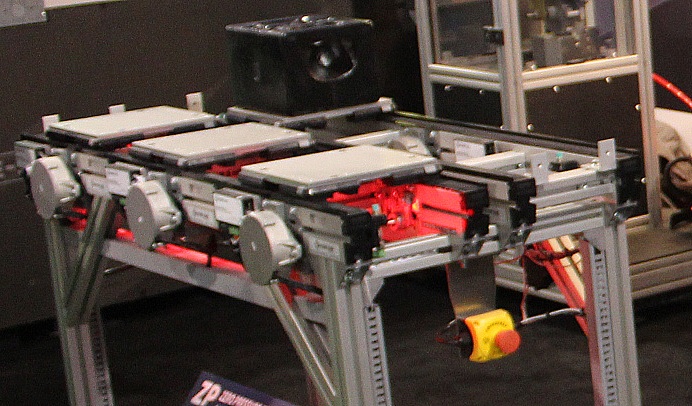

Your customer’s precision products can often require special handling. After all, they need to ensure proper assembly without damage, scuffing, sticking, or jarring in the conveying process. But specialization in conveyor design could create fear of the dreaded “C” word – customization. Customizations can blow your client’s budget quicker than an Aaron Rodgers injury can derail a Packers season. Instead, consider these five ways Glide-Line’s innovative, flexible conveyor systems help avoid damage to your clients’ precision products.

Read More