Zero Contact Zoned Conveyors are ideal when transporting fragile and sterile products in totes while eliminating the need for pneumatic stops. These zoned conveying systems keep products on individual pallets, totes or trays as they move across the line.

They ensure an elegant movement of your payload as it moves across the conveyor to eliminate product damage.

With gentle stops and smooth starts, these DC pancake motor driven zoned systems also reduce the wear and tear on the conveying systems. That means less downtime.

Let's look at the three improvements you can make to your conveying line if you're transporting totes and need to reduce friction on your conveying system.

3 Improvements to Transferring Totes On and Off the Conveyor Line

Here are three improvements to your conveyor line when transferring your products in totes:

Know Your Load

Know Your Load

Delicate parts require precision conveying. Totes containing fragile materials risk damaging the parts when moved from one zone to the next during the conveying process. The Zero Contact Zoned Conveyor solution allows you to gently convey and accumulate your products with or without a workpiece pallet.

When configuring your conveying system, consider the load you will be transporting. If you want to reduce damage to products on your conveyor system without putting a product on a pallet, zoned conveyors convey and accumulate your product directly on the line gently without a workpiece pallet ensuring that products never touch and there is no damage to your load.

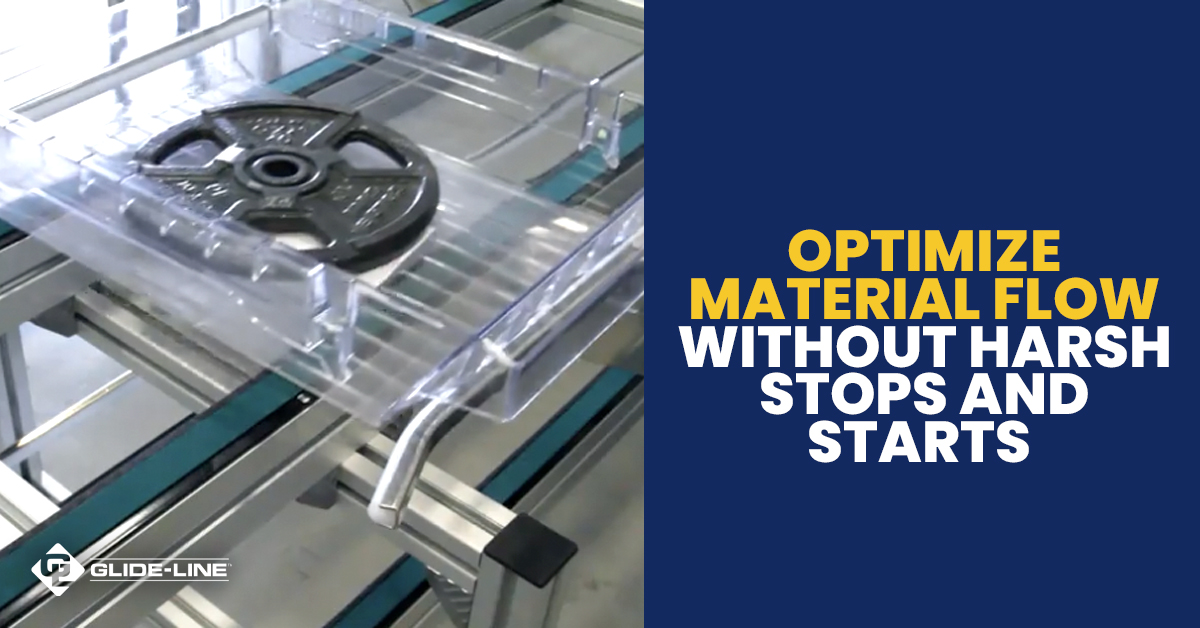

Optimize Material Flow

Optimize Material Flow

The zoned approach allows for more repeatable modules throughout the system and you can add efficient, space saving solutions along the way, like a Rotation Unit or a Vertical Transport Unit (VTU).

It simplifies the scheme of the system because it allows you to accumulate the product in individual zones. Lift, transfer, or rotate, or hand it off between processes to optimize material flow without harsh stops and starts.

It’s straightforward, gentle handling. By incorporating zoned conveying into the equation, you eliminate jarring the products against each other.

Achieve Precise Control

Achieve Precise Control

The Zero Contact Zoned Conveyor can pair with a photo eye or other sensor to start and stop the conveyor right when needed to ensure precision control on your line. Move product across the line at different speeds to maximize throughput.

The Zero Contact Zoned Conveyor can pair with a photo eye or other sensor to start and stop the conveyor right when needed to ensure precision control on your line. Move product across the line at different speeds to maximize throughput.

For heavier totes, our Roller Chain solution allows you to install pallet sensors with logic to control starts and stops. It offers dampened and undampened stops for very precise and repeatable stopping points for products.

This is an excellent solution for many applications needing the same controlled process, but for wide or long totes or products.

Let Glide-Line Conveyors Transport Your Delicate Products

Industries of all types are using evolving conveyor systems during production, processing, and packaging. Economists believe the conveyor system market size will reach $15 billion by 2023. They believe this growth is related to innovations in the technology and design of these conveyors. We are proud to continue to develop and bring our engineering customers the latest and greatest conveying solutions and technology.

These innovations in design and technology are helping improve the conveying process, especially for fragile materials transported in totes. At Glide-Line, our Zero Contact Zoned Conveyors will protect your products transferred in totes.

Contact us to learn more about our Zero Contact Zoned Conveyors.

Leave a Comment