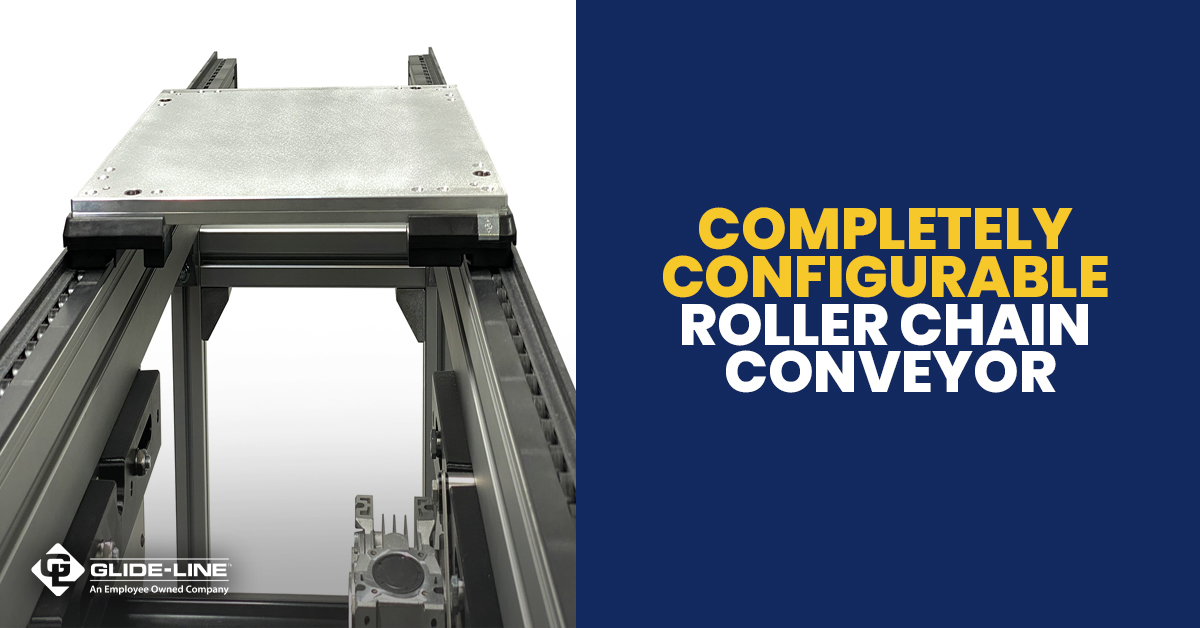

In this ebook, we share how to combat surprises in your design change management process more easily, efficiently, and precisely. Combine steps and maximize the time you spend designing your project, and minimize time spent on changes and updates to your designs. Have you ever wanted to: Get the pricing, part numbers, and conveyor design changes done yourself and on your own time, without involving a sales rep? Use CAD models that have pre-configured SOLIDWORKS mates - and make changes to them in-context? Create a unique conveyor solution that's exactly right for you or your client, and doesn't cost more? You don’t have time to waste. Download this practical guide and find out how today.

Read More