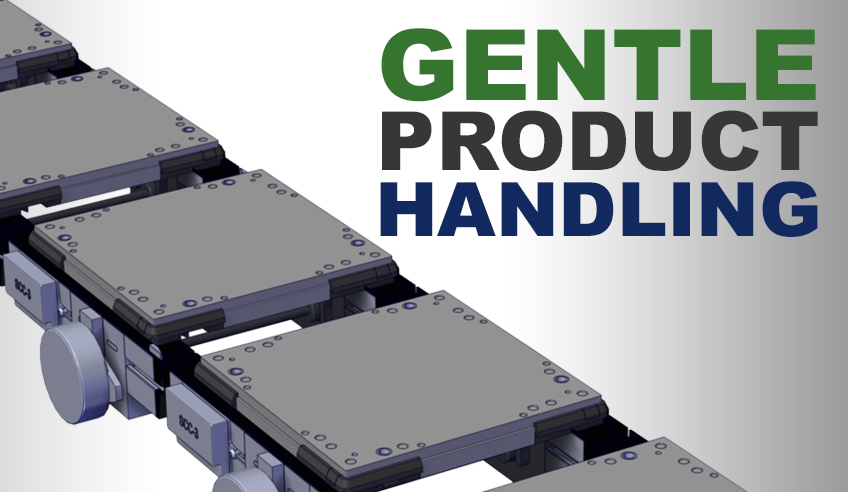

When it comes to smooth handling, traditional conveyor transportation leaves a lot to be desired. This is especially the case when moving and accumulating product between assembly stations. A stop in the line can easily cause pallets to bang into each other, leading to product damage. Many are searching for a better solution, so we introduced Glide-Line’s Zero Contact Zoned Conveyor. With Glide-Line’s Zero Contact Zoned Conveyor solution, “hard stops” are a thing of the past. With products moving smoothly from station to station, partially and fully-assembled products can be handled without the risk of product damage.

Read More